Impact of shock testing on material durability

The Crucial Role of Impact Testing in Ensuring Material Durability Why Eurolab is Your Trusted Partner

In todays fast-paced and highly competitive business environment, companies are constantly seeking ways to improve product quality, reduce costs, and enhance customer satisfaction. One critical aspect that often gets overlooked is the durability of materials used in manufacturing processes. A materials ability to withstand various environmental factors, mechanical stress, and other external influences is vital for ensuring its longevity and performance.

What is Impact Testing on Material Durability?

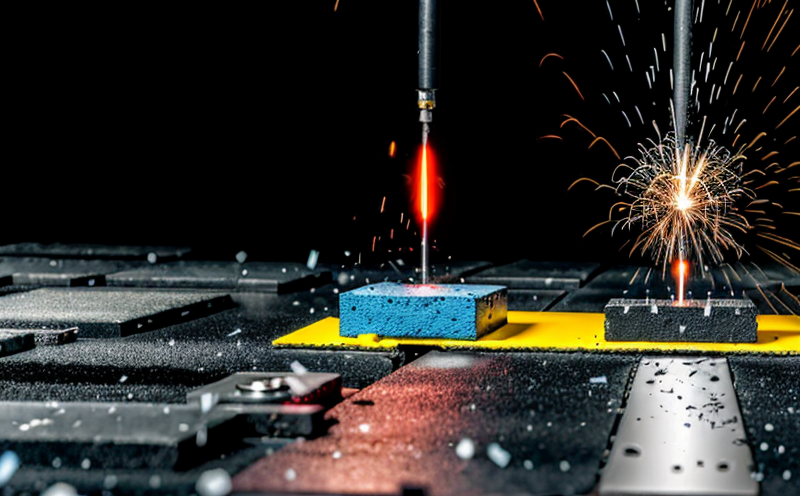

Impact testing, also known as shock testing or drop testing, is a laboratory service that simulates the effects of physical shocks, drops, or impacts on materials. This non-destructive test evaluates a materials ability to withstand sudden and intense forces, which can cause damage or failure. By subjecting materials to controlled impact tests, Eurolab helps businesses understand their products true durability and potential risks.

Why is Impact Testing Essential for Businesses?

In todays complex market landscape, the consequences of inadequate material durability can be far-reaching

Product Failure Materials that cannot withstand impacts may fail prematurely, leading to costly product recalls, lost sales, and damaged brand reputation.

Safety Concerns Products with fragile or brittle materials pose a risk to consumers, which can result in financial liability and regulatory non-compliance.

Quality Control Companies that prioritize material durability enjoy higher product quality, reduced warranty claims, and increased customer satisfaction.

Advantages of Using Impact Testing on Material Durability

Eurolabs impact testing services offer numerous benefits for businesses

Improved Product Reliability Identify potential weaknesses in materials to enhance overall product robustness.

Enhanced Safety Features Ensure compliance with regulatory standards by simulating real-world scenarios.

Cost Savings Prevent product failures, warranty claims, and recalls by understanding material limitations.

Competitive Advantage Develop products that stand out for their durability, quality, and performance.

Some key benefits of Eurolabs impact testing services are

Comprehensive Testing Methods Choose from various impact test methods to suit specific business needs (e.g., drop testing, shock testing, and vibration testing).

State-of-the-Art Equipment Utilize advanced equipment and technology to ensure accurate and reliable results.

Expert Analysis Receive detailed reports and expert analysis to help businesses make informed decisions.

How Does Eurolabs Impact Testing Service Work?

The impact testing process is straightforward

Sample Preparation Send your product or material sample to Eurolab for evaluation.

Test Selection Choose the relevant impact test method based on your specific business requirements.

Testing and Analysis Our team conducts the impact test, collecting data and analyzing results.

Reporting and Consultation Receive a detailed report outlining findings, recommendations, and suggestions for material improvements.

Frequently Asked Questions (FAQs)

What types of materials can be tested?

Eurolabs impact testing services cover various materials, including metals, plastics, composites, ceramics, and textiles.

How long does the testing process take?

Test duration depends on the specific test method and material complexity; average turnaround time is typically 1-5 business days.

Can I customize my impact testing program?

Yes, Eurolab works closely with clients to tailor impact testing programs that meet unique business requirements.

How accurate are the results?

Eurolabs advanced equipment and expert analysis ensure precise and reliable test results.

Conclusion

In an increasingly competitive market, companies must prioritize material durability to maintain product quality, customer satisfaction, and brand reputation. Eurolabs impact testing services offer a comprehensive solution for evaluating materials under controlled shock conditions. By leveraging our expertise and state-of-the-art equipment, businesses can identify potential weaknesses, enhance safety features, reduce costs, and enjoy a competitive edge.

Dont let material durability compromise your products performance. Choose Eurolabs trusted laboratory services to ensure the longevity and reliability of your products.