Real-time monitoring of shock resistance in operational environments

Real-Time Monitoring of Shock Resistance in Operational Environments Ensuring the Reliability and Durability of Your Products

In todays fast-paced and increasingly competitive business landscape, companies are constantly seeking ways to improve efficiency, reduce costs, and enhance product quality. One critical aspect of ensuring the reliability and durability of products is testing their shock resistance the ability to withstand sudden and intense impacts without sustaining damage or compromising performance. However, traditional laboratory testing methods can be time-consuming, costly, and may not accurately reflect real-world conditions.

Thats where Eurolab comes in. Our Real-time monitoring of shock resistance in operational environments service provides businesses with a cutting-edge solution for testing the shock resistance of their products under realistic conditions, ensuring that they meet the highest standards of quality and reliability.

What is Real-Time Monitoring of Shock Resistance in Operational Environments?

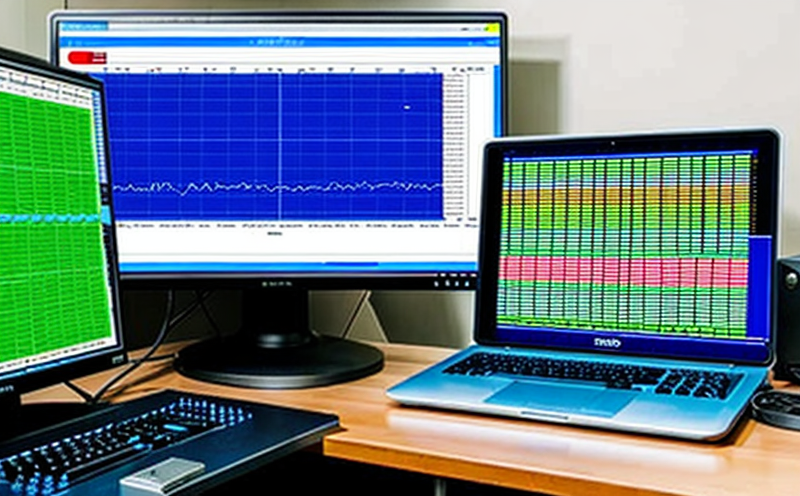

Real-Time monitoring of shock resistance in operational environments involves using advanced sensors and data analysis software to monitor the performance of products as they undergo shock testing. This service allows Eurolab to provide clients with accurate and detailed information on a products shock resistance, including its ability to withstand various types and levels of impact.

Unlike traditional laboratory testing methods, which often involve static or simulated testing conditions that may not accurately reflect real-world scenarios, our Real-time monitoring service simulates the actual operational environments in which products are used. This means that clients can rest assured that their products have been tested under conditions that closely mimic those they will encounter in use.

Why is Real-Time Monitoring of Shock Resistance in Operational Environments Essential for Businesses?

In todays global marketplace, companies must be able to demonstrate the reliability and durability of their products to maintain customer trust and loyalty. Here are just a few reasons why our Real-time monitoring service is essential for businesses

Enhanced Product Quality By testing products under realistic conditions, Eurolab ensures that clients receive accurate information about their products shock resistance.

Improved Efficiency Our Real-time monitoring service eliminates the need for time-consuming and costly laboratory testing methods, allowing clients to get the information they need quickly and efficiently.

Reduced Risk By identifying potential weaknesses in products before they are released to market, companies can reduce the risk of product failure, damage to reputation, and financial loss.

Key Benefits of Using Eurolabs Real-Time Monitoring Service

Here are just a few key benefits of using our Real-time monitoring service

Accurate Results Our advanced sensors and data analysis software ensure that clients receive accurate and reliable results.

Realistic Testing Conditions By simulating real-world conditions, our testing methodology provides a more accurate representation of product performance in operational environments.

Cost Savings Our service eliminates the need for costly laboratory testing methods, saving clients time and money.

Improved Product Design By identifying areas for improvement, companies can design products that meet the highest standards of quality and reliability.

QA Real-Time Monitoring of Shock Resistance in Operational Environments

Here are some frequently asked questions about our Real-time monitoring service

What types of products can be tested using Eurolabs Real-Time monitoring service?

Our service can be used to test a wide range of products, including those that require shock resistance testing.

How long does the testing process take?

The length of time required for testing will depend on the specific product being tested and the level of detail required by the client.

Is the data collected during testing confidential?

Yes, all data collected during testing is confidential and protected in accordance with applicable laws and regulations.

Conclusion

In todays competitive business landscape, companies must be able to demonstrate the reliability and durability of their products. Eurolabs Real-time monitoring service provides businesses with a cutting-edge solution for testing shock resistance under realistic conditions, ensuring that clients receive accurate and reliable results.

By choosing our service, clients can

Enhance product quality

Improve efficiency

Reduce risk

Dont compromise on the reliability and durability of your products. Contact Eurolab today to learn more about our Real-time monitoring service and how we can help you achieve your business goals.

Benefits Summary

Here are the key benefits of using Eurolabs Real-time monitoring service

Accurate Results

Realistic Testing Conditions

Cost Savings

Improved Product Design

By choosing our service, clients can enhance product quality, improve efficiency, and reduce risk. Contact us today to learn more about how we can help you achieve your business goals.

Get in Touch with Eurolab

To learn more about our Real-time monitoring service or to schedule a consultation, please contact us using the form on our website.

By choosing Eurolabs Real-time monitoring service, businesses can ensure that their products meet the highest standards of quality and reliability. Dont compromise choose the best.