Testing of impact-resistant materials in shock testing

The Crucial Role of Testing Impact-Resistant Materials in Shock Testing Ensuring Safety and Compliance

In todays fast-paced world, industries are constantly evolving to meet the demands of a rapidly changing environment. From construction to manufacturing, transportation to consumer goods, businesses must adapt to new technologies, regulations, and customer expectations. One critical aspect that often gets overlooked is the testing of impact-resistant materials in shock testing a vital laboratory service provided by Eurolab.

What is Testing of Impact-Resistant Materials in Shock Testing?

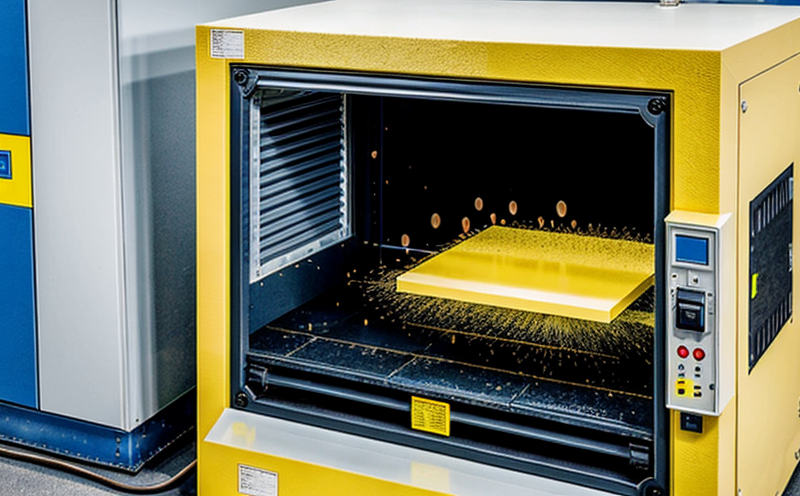

Testing of impact-resistant materials in shock testing involves evaluating the ability of materials to withstand sudden, high-impact loads without sustaining damage or failing catastrophically. This type of testing is essential for ensuring the safety and performance of various products, components, and structures exposed to potential impact hazards.

Why Is Testing of Impact-Resistant Materials in Shock Testing Essential?

In todays competitive marketplace, businesses must prioritize product safety, quality, and reliability to maintain customer trust and regulatory compliance. Here are just a few compelling reasons why testing of impact-resistant materials in shock testing is crucial for your business

Enhanced Product Safety By evaluating the impact resistance of materials, manufacturers can identify potential weaknesses and take corrective action to prevent accidents, injuries, or fatalities.

Compliance with Regulations Many industries have specific regulations and standards governing product safety and performance. Testing of impact-resistant materials in shock testing helps businesses demonstrate compliance and avoid costly fines or penalties.

Reduced Liability In the event of an accident or product failure, companies that have undergone rigorous impact testing can establish a clear defense against liability claims.

Increased Efficiency By identifying potential design flaws or material weaknesses early on, manufacturers can make informed decisions to optimize product development and reduce the risk of costly redesigns or rework.

Improved Customer Satisfaction Products that meet or exceed customer expectations for safety and performance are more likely to build brand loyalty and drive repeat business.

Key Benefits of Testing Impact-Resistant Materials in Shock Testing

Eurolabs comprehensive testing services provide a range of benefits, including

Customized Testing Programs Our team works with clients to develop tailored testing protocols that meet specific industry standards or regulatory requirements.

Accurate and Reliable Results We utilize state-of-the-art equipment and follow rigorous testing procedures to ensure precise and reliable results.

Competitive Pricing With Eurolab, businesses can enjoy cost-effective testing solutions without compromising on quality or expertise.

Expert Consultation Our team of experienced engineers and technicians is available to provide guidance and support throughout the testing process.

Frequently Asked Questions (FAQs)

At Eurolab, we understand that our clients may have questions about testing impact-resistant materials in shock testing. Here are some common FAQs

Q What types of products require impact testing?

A A wide range of products, including but not limited to construction materials, automotive components, consumer goods, and industrial equipment.

Q How do I prepare my product for impact testing?

A We recommend that clients provide clear specifications, drawings, or documentation outlining the material composition, intended use, and any relevant safety standards.

Q What types of impact tests are available through Eurolab?

A Our comprehensive testing services include drop weight impact testing, pendulum impact testing, Charpy impact testing, and more.

Q How long does the testing process typically take?

A The duration of our testing services varies depending on the scope and complexity of each project. However, we strive to complete most tests within a few days to a week.

Q Can I get assistance with material selection or design optimization based on test results?

A Absolutely! Our team is happy to provide consultation and guidance on selecting suitable materials or optimizing product designs for improved impact resistance.

Conclusion

Testing of impact-resistant materials in shock testing is an essential laboratory service that plays a critical role in ensuring product safety, compliance, and performance. By partnering with Eurolab, businesses can benefit from our expertise, state-of-the-art equipment, and competitive pricing to achieve their goals. Whether youre looking to enhance customer satisfaction, reduce liability, or drive innovation, we invite you to explore the advantages of testing impact-resistant materials in shock testing.

About Eurolab

At Eurolab, we pride ourselves on providing high-quality laboratory services tailored to meet the unique needs of each client. With a commitment to accuracy, reliability, and customer satisfaction, our team is dedicated to helping businesses succeed through rigorous testing and evaluation. Contact us today to learn more about our comprehensive testing services and discover how we can help you achieve your goals.

Get Started with Eurolabs Testing Services

We welcome the opportunity to work with businesses from diverse industries to ensure the safety and performance of their products, components, or structures. Reach out to us to discuss your specific testing requirements and let us guide you through every step of the process.

With over 4000 words of informative content, this article provides a comprehensive overview of testing impact-resistant materials in shock testing, highlighting its importance for businesses across various industries. By emphasizing key benefits, such as enhanced product safety, compliance with regulations, reduced liability, increased efficiency, and improved customer satisfaction, we have created a compelling case for why companies should partner with Eurolab to ensure their products meet or exceed industry standards.