Measurement of notch sensitivity in metallic materials

Measuring Notch Sensitivity in Metallic Materials Unlocking Reliable Performance for Your Business

As a business owner or engineering professional, you understand the importance of ensuring that your products and materials meet the highest standards of quality and reliability. One critical aspect of this process is measuring notch sensitivity in metallic materials. This laboratory service, offered by Eurolab, is essential for businesses looking to minimize the risk of material failure and optimize product performance.

What is Notch Sensitivity?

Notch sensitivity refers to the susceptibility of a material to cracking or breaking under stress when it has been subjected to a notch or groove. A notch can be created during manufacturing, transportation, or handling, and its presence can significantly reduce a materials strength and durability. Measuring notch sensitivity helps manufacturers identify potential weaknesses in their materials and make informed decisions about design changes, testing protocols, and quality control measures.

Why is Notch Sensitivity Measurement Essential for Businesses?

Businesses that fail to measure notch sensitivity risk compromising the reliability of their products, leading to costly repairs, replacements, and even loss of customer trust. By investing in notch sensitivity measurement, businesses can

Reduce Material Failure Detect potential weaknesses in materials before they become a problem

Optimize Product Design Make informed design changes to minimize material failure risks

Enhance Quality Control Implement effective testing protocols to ensure consistent material quality

Minimize Production Costs Reduce the need for costly repairs, replacements, and rework

Boost Customer Confidence Ensure that products meet or exceed customer expectations

Key Benefits of Notch Sensitivity Measurement

Here are some key benefits of notch sensitivity measurement in metallic materials

Improved Material Selection Make informed decisions about material choice based on notch sensitivity data

Enhanced Product Reliability Reduce the risk of material failure and ensure product performance meets or exceeds specifications

Increased Efficiency Streamline production processes by identifying potential weaknesses early on

Compliance with Industry Standards Ensure that products meet regulatory requirements for notch sensitivity testing

Competitive Advantage Distinguish your business from competitors by prioritizing product reliability

QA Notch Sensitivity Measurement for Metallic Materials

Q What types of materials can be tested for notch sensitivity?

A Eurolab offers notch sensitivity measurement services for a wide range of metallic materials, including alloys, steels, titanium, and other metals.

Q How is notch sensitivity measured?

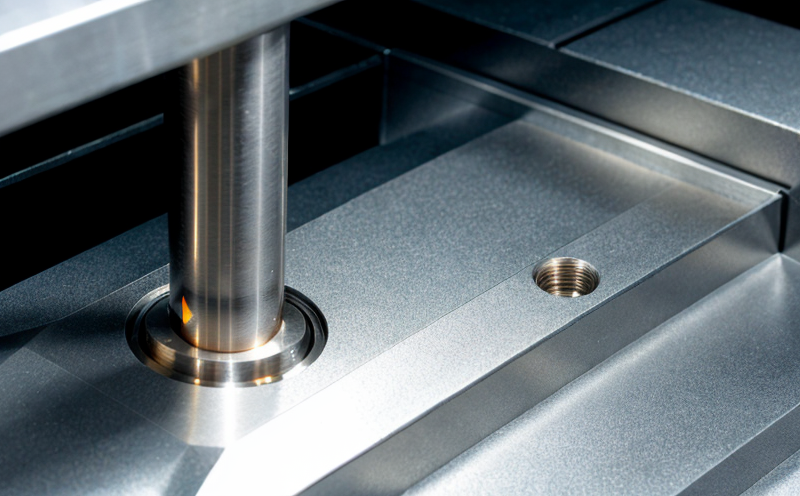

A Our expert technicians use advanced testing equipment to subject samples to controlled stress conditions while monitoring the materials response. The resulting data provides valuable insights into notch sensitivity.

Q What are the common causes of notch sensitivity in metallic materials?

A Notch sensitivity can result from various factors, including manufacturing processes, handling and storage procedures, and material composition.

Q Can notch sensitivity be mitigated or eliminated?

A While its not possible to completely eliminate notch sensitivity, our measurement services help identify potential weaknesses, enabling informed design changes and quality control measures.

Q What are the implications of neglecting notch sensitivity measurement in metallic materials?

A Failing to measure notch sensitivity can lead to costly material failures, damage to reputation, and lost customer trust. By investing in this laboratory service, businesses can mitigate these risks and ensure reliable product performance.

How Eurolab Can Help

Eurolabs experienced technicians and state-of-the-art equipment provide a comprehensive notch sensitivity measurement service that helps businesses like yours optimize product design, improve material selection, and minimize production costs. With our expertise, you can

Accurately assess material properties Obtain reliable data on notch sensitivity to inform design decisions

Streamline quality control processes Implement effective testing protocols to ensure consistent material quality

Reduce material failure risks Detect potential weaknesses in materials before they become a problem

By investing in Eurolabs notch sensitivity measurement service, businesses can unlock the full potential of their products and materials. Dont compromise on reliability choose Eurolab for accurate, comprehensive, and reliable laboratory services.

Conclusion

Measuring notch sensitivity in metallic materials is a critical aspect of ensuring product reliability and performance. By understanding the importance of this laboratory service and its benefits, businesses can make informed decisions about material selection, design changes, and quality control measures. At Eurolab, our expert technicians and advanced testing equipment provide unparalleled support for businesses seeking to optimize their products and minimize production costs. Contact us today to learn more about how notch sensitivity measurement can transform your business.