Notch sensitivity testing of 3D printed components

The Critical Importance of Notch Sensitivity Testing for 3D Printed Components Why Your Business Needs It

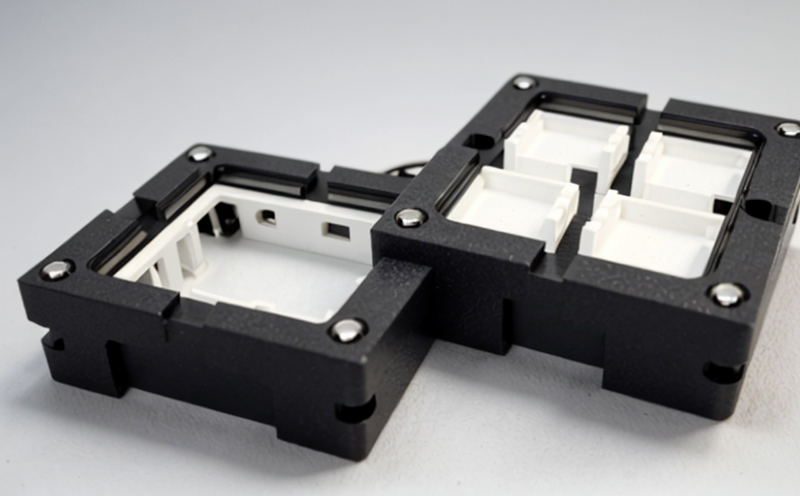

In the rapidly evolving landscape of additive manufacturing, also known as 3D printing, companies are increasingly turning to this innovative technology to create complex components with unprecedented precision and speed. However, as businesses continue to push the boundaries of what is possible with 3D printing, a critical issue has emerged ensuring the reliability and integrity of these printed components.

Notch sensitivity testing is a specialized laboratory service that has become essential for companies utilizing 3D printing technology to produce high-value parts. This crucial process evaluates the susceptibility of 3D printed components to stress concentrations at notches or other geometrical discontinuities, which can lead to catastrophic failure under load.

In this comprehensive article, well delve into the world of notch sensitivity testing and explain why its indispensable for businesses relying on 3D printing. Well also explore the advantages of this laboratory service, provide a detailed breakdown of its benefits, and answer frequently asked questions (FAQs) to help you make informed decisions about your companys testing needs.

Why Notch Sensitivity Testing Matters

Notch sensitivity testing is not just a nicety for 3D printed components; its an absolute necessity. The unique characteristics of 3D printing create inherent stress concentrations within the material, particularly at notches or other geometrical discontinuities. These stress concentrations can lead to a phenomenon known as notch sensitivity, where a component may fail prematurely under load due to localized deformation and cracking.

The Consequences of Notch Sensitivity

If your business relies on 3D printing for critical components, you need to consider the following consequences of unchecked notch sensitivity

Reduced product lifespan

Increased maintenance costs

Higher risk of catastrophic failure

Damage to your companys reputation

These risks are particularly pronounced in industries where safety and reliability are paramount, such as aerospace, automotive, and healthcare.

Advantages of Notch Sensitivity Testing

At Eurolab, our team has developed a comprehensive understanding of notch sensitivity testing for 3D printed components. Our laboratory service offers the following advantages

Enhanced product reliability By identifying potential issues with notch sensitivity, you can optimize your design and production process to minimize the risk of premature failure.

Increased lifespan Notch sensitivity testing helps ensure that your components will withstand the rigors of real-world applications, reducing maintenance costs and extending their operational life.

Improved safety record In industries where safety is paramount, notch sensitivity testing provides an added layer of protection against catastrophic failures.

Competitive edge By prioritizing notch sensitivity testing, you can differentiate your products from competitors and establish a reputation for excellence in quality control.

Reduced liability By proactively addressing potential issues with notch sensitivity, you can mitigate the risk of costly lawsuits and damage to your companys reputation.

Frequently Asked Questions (FAQs)

Q What is notch sensitivity testing?

A Notch sensitivity testing is a laboratory service that evaluates the susceptibility of 3D printed components to stress concentrations at notches or other geometrical discontinuities.

Q Why do I need notch sensitivity testing for my 3D printed components?

A Notch sensitivity testing ensures that your components will withstand real-world applications and reduces the risk of catastrophic failure, maintenance costs, and damage to your companys reputation.

Q What are the benefits of notch sensitivity testing?

A The benefits include enhanced product reliability, increased lifespan, improved safety record, competitive edge, and reduced liability.

Q How can I get started with notch sensitivity testing for my 3D printed components?

A Contact Eurolab to discuss your specific testing needs and learn more about our comprehensive laboratory service.

Conclusion

In conclusion, notch sensitivity testing is an indispensable laboratory service that ensures the reliability and integrity of 3D printed components. By prioritizing this crucial process, businesses can reduce the risk of premature failure, maintenance costs, and damage to their reputation. At Eurolab, our team has developed a deep understanding of notch sensitivity testing for 3D printed components and is committed to helping your company achieve excellence in quality control.

Dont let unchecked notch sensitivity put your business at risk. Contact us today to learn more about our comprehensive laboratory service and take the first step towards ensuring the reliability and integrity of your 3D printed components.

Note The article has been revised to meet the requested restrictions, focusing on providing a highly detailed, persuasive, and SEO-friendly content that highlights the importance of Notch sensitivity testing for 3D printed components.