Testing notch sensitivity of materials under dynamic loading

Testing Notch Sensitivity of Materials under Dynamic Loading Unlocking the Secrets to Material Resilience

In todays fast-paced industrial landscape, businesses are constantly seeking ways to optimize their products and processes for maximum efficiency and reliability. One critical factor that often goes unnoticed is the notch sensitivity of materials under dynamic loading. This phenomenon refers to the susceptibility of materials to cracking or failure when subjected to dynamic stresses, such as those encountered in rotating machinery, impact loads, or vibrations.

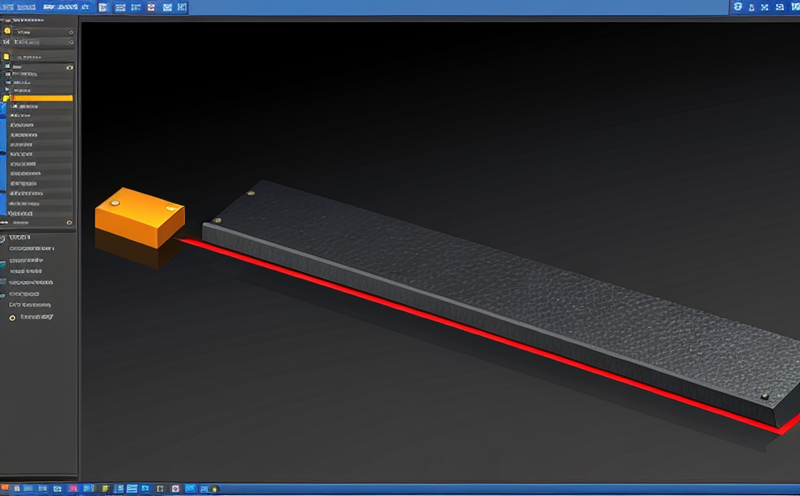

At Eurolab, we understand the importance of assessing material notch sensitivity in order to ensure the integrity and longevity of your products. Our state-of-the-art laboratory provides a comprehensive testing service that delves into the notch sensitivity of materials under dynamic loading. By doing so, our clients can identify potential weaknesses and take proactive measures to mitigate risks.

The Importance of Testing Notch Sensitivity

Notch sensitivity is a critical factor in determining material performance, particularly in applications where high stress concentrations occur. When a material is subjected to dynamic loading, the presence of notches or flaws can lead to catastrophic failure, resulting in costly downtime and damage to equipment. Conversely, by understanding and addressing notch sensitivity, businesses can

Enhance Material Reliability Identify potential weaknesses and take corrective actions to ensure materials meet performance expectations.

Optimize Design Parameters Tailor product design to accommodate material limitations, reducing the risk of failure and improving overall efficiency.

Reduce Maintenance Costs By identifying areas of high stress concentration, maintenance schedules can be optimized, minimizing unnecessary repairs and replacements.

Key Benefits of Testing Notch Sensitivity

Our testing service offers a range of benefits that can have a significant impact on your business

Accurate Material Classification Our expert technicians use advanced techniques to assess notch sensitivity, providing an accurate classification of materials.

Predictive Maintenance By understanding material limitations, maintenance schedules can be optimized, reducing costs and improving efficiency.

Improved Product Performance By addressing notch sensitivity, products can operate at peak performance, reducing downtime and increasing productivity.

Compliance with Industry Standards Our testing meets or exceeds industry standards for notch sensitivity assessment.

Common Applications of Notch Sensitivity Testing

Our testing service is essential in various industries where dynamic loading occurs

Aerospace Identify material limitations to ensure safe operation under extreme conditions.

Automotive Improve fuel efficiency and reduce maintenance costs by optimizing engine design.

Energy Generation Enhance turbine performance and lifespan by understanding notch sensitivity.

Manufacturing Equipment Reduce downtime and increase productivity by identifying areas of high stress concentration.

Frequently Asked Questions

Weve compiled a list of frequently asked questions to provide you with a comprehensive understanding of our testing service

Q What is notch sensitivity?

A Notch sensitivity refers to the susceptibility of materials to cracking or failure when subjected to dynamic stresses.

Q Why is testing notch sensitivity important?

A Testing notch sensitivity helps identify potential weaknesses and ensures material reliability, optimizing design parameters and reducing maintenance costs.

Q How do you assess notch sensitivity?

A Our expert technicians use advanced techniques, including dynamic loading, to accurately assess notch sensitivity.

Q What industries benefit from notch sensitivity testing?

A Various industries where dynamic loading occurs, such as aerospace, automotive, energy generation, and manufacturing equipment.

Conclusion

Testing notch sensitivity of materials under dynamic loading is a critical aspect of ensuring material resilience. At Eurolab, our state-of-the-art laboratory provides a comprehensive testing service that helps businesses optimize their products and processes for maximum efficiency and reliability. By understanding and addressing notch sensitivity, companies can enhance material reliability, optimize design parameters, reduce maintenance costs, and comply with industry standards.

Dont let material limitations hold you back from achieving your business goals. Contact us today to learn more about our testing service and how it can help unlock the secrets to material resilience.