Measuring Contact Resistance in Electrical Connections

Measuring Contact Resistance in Electrical Connections Ensuring Efficiency, Reliability, and Safety

In todays fast-paced industrial landscape, electrical connections play a vital role in the smooth operation of equipment and machinery. However, even the smallest issues with these connections can lead to significant downtime, decreased productivity, and increased maintenance costs. One critical aspect that is often overlooked but crucial for maintaining efficient and reliable electrical connections is measuring contact resistance. At Eurolab, our laboratory services specialize in providing expert analysis of contact resistance in electrical connections, helping businesses optimize their operations and ensure the safety of their personnel.

What is Measuring Contact Resistance in Electrical Connections?

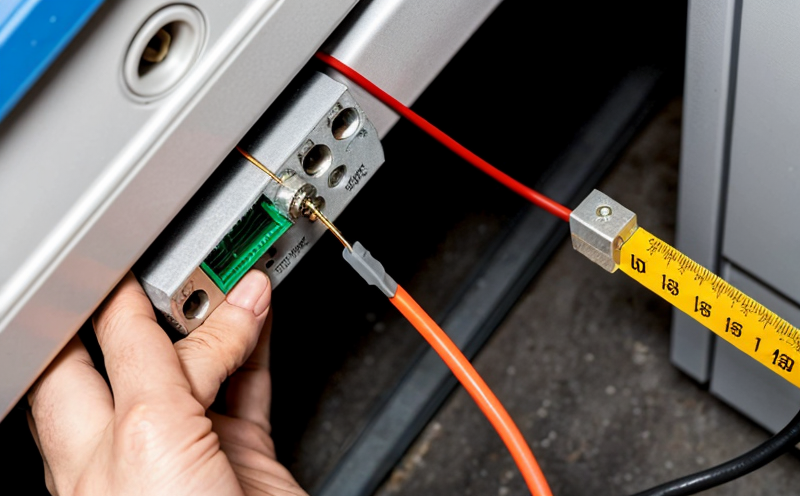

Measuring contact resistance refers to the process of determining the electrical resistance at the interface between two conductive materials, typically in a switch, connector, or other type of electrical connection. This measurement provides valuable insights into the performance and reliability of the connection, allowing for timely identification and rectification of any issues that may arise.

Why is Measuring Contact Resistance Essential for Businesses?

Incorporating contact resistance measurement into your quality control protocols can have a profound impact on your operations. Here are some compelling reasons why

Ensures Reliable Operation By monitoring contact resistance, you can prevent equipment failures and ensure continuous operation, reducing downtime and increasing overall productivity.

Improves Safety Identifying and addressing high-resistance connections helps prevent electrical shock, fires, and other safety hazards that can put personnel at risk.

Extends Equipment Life Regular measurement of contact resistance enables early detection of wear and tear on electrical connections, allowing for proactive maintenance and replacement before costly repairs are needed.

Complies with Industry Standards By incorporating contact resistance measurement into your quality control protocols, you can demonstrate compliance with industry standards and regulatory requirements.

Key Benefits of Measuring Contact Resistance in Electrical Connections

Here are the key benefits of measuring contact resistance in electrical connections

Early Detection of Issues Regular contact resistance measurements enable early detection of issues that may lead to equipment failure or safety hazards.

Improved Maintenance Scheduling By identifying potential problems before they occur, you can schedule maintenance and repairs during planned downtime, reducing costs and increasing productivity.

Reduced Downtime Identifying high-resistance connections allows for prompt replacement or repair, minimizing the risk of equipment failure and associated downtime.

Compliance with Industry Regulations Regular contact resistance measurements demonstrate compliance with industry standards and regulatory requirements.

How to Ensure Accurate Measurement Results

To ensure accurate measurement results, follow these best practices

Proper Instrument Calibration Calibrate your measuring instruments regularly to ensure accuracy and reliability.

Correct Sampling Techniques Use proper sampling techniques to obtain representative measurements of contact resistance.

Data Analysis and Interpretation Analyze and interpret data correctly to identify trends, anomalies, and areas for improvement.

QA Frequently Asked Questions About Measuring Contact Resistance in Electrical Connections

Here are answers to some frequently asked questions about measuring contact resistance

Q What is the importance of measuring contact resistance in electrical connections?

A Measuring contact resistance helps ensure reliable operation, improves safety, extends equipment life, and complies with industry standards.

Q How often should I measure contact resistance?

A The frequency of measurement depends on the specific application, but regular monitoring is essential to prevent issues from arising.

Q What instruments are used to measure contact resistance?

A Various instruments, including ohmmeters and multimeters, can be used to measure contact resistance.

Conclusion

Measuring contact resistance in electrical connections is a critical aspect of maintaining efficient, reliable, and safe operations. By incorporating this laboratory service into your quality control protocols, you can ensure compliance with industry standards, reduce downtime and maintenance costs, and protect personnel from electrical hazards. At Eurolab, our experts are dedicated to providing accurate and reliable measurement results that help businesses optimize their operations and achieve success in an increasingly competitive landscape.