Testing the Durability of Contacts in Power Connectors

Testing the Durability of Contacts in Power Connectors A Crucial Laboratory Service for Businesses

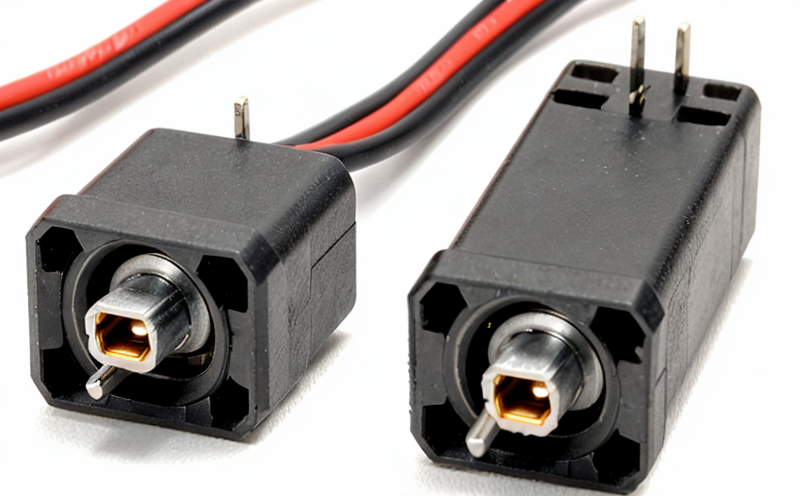

In todays fast-paced and highly competitive business landscape, ensuring the reliability and durability of electrical components is more crucial than ever. One often-overlooked aspect of this is the integrity of power connectors, which are responsible for transmitting high currents and voltages between devices. The contacts within these connectors can be prone to wear and tear, leading to faulty connections, overheating, and even fires.

This is where Testing the Durability of Contacts in Power Connectors comes into play - a vital laboratory service provided by Eurolab that helps businesses verify the performance and lifespan of their power connector contacts. By identifying potential issues early on, companies can prevent costly downtime, improve product reliability, and avoid regulatory compliance problems.

In this article, well delve into the benefits of using Testing the Durability of Contacts in Power Connectors, explore its key advantages, and provide a comprehensive QA section to address any queries you may have. So, lets dive right in!

What is Testing the Durability of Contacts in Power Connectors?

Testing the durability of contacts in power connectors involves subjecting the components to various stress tests to evaluate their resistance to wear and tear over time. This laboratory service uses specialized equipment and expert technicians to simulate real-world conditions, such as

Electrical loads

Vibration

Thermal cycling

Corrosion

The results provide valuable insights into the connectors performance under different scenarios, helping businesses optimize their designs, manufacturing processes, and testing protocols.

Why is Testing the Durability of Contacts in Power Connectors essential for businesses?

There are numerous reasons why companies should prioritize Testing the Durability of Contacts in Power Connectors. Here are some key benefits

Advantages of Using Eurolabs Laboratory Service

Improved Product Reliability By identifying potential issues early on, you can ensure that your products meet industry standards and regulations.

Reduced Downtime Minimize costly downtime by verifying the performance and lifespan of power connector contacts, reducing the likelihood of component failure.

Enhanced Customer Satisfaction Deliver high-quality products that meet customer expectations, leading to increased satisfaction and loyalty.

Compliance with Industry Regulations Stay ahead of regulatory requirements and industry standards, ensuring your business remains compliant and competitive.

Benefits for Manufacturers

Optimized Design and Manufacturing Leverage test data to refine designs and improve manufacturing processes, reducing production costs and lead times.

Increased Efficiency Streamline quality control procedures by verifying the performance and lifespan of power connector contacts.

Reduced Warranty Claims Minimize warranty claims and returns by identifying potential issues before they become major problems.

Benefits for Businesses

Cost Savings Avoid costly rework, repairs, or replacement of faulty components, leading to significant cost savings.

Competitive Advantage Differentiate your business from competitors by ensuring the highest quality products and services.

Improved Supply Chain Management Enhance supply chain efficiency by verifying the performance and lifespan of power connector contacts.

Benefits for Research and Development

Informed Decision Making Leverage test data to inform design and development decisions, reducing the risk of costly mistakes.

Accelerated Product Development Speed up product development cycles by verifying the performance and lifespan of power connector contacts early on.

Increased Innovation Explore new designs and materials with confidence, knowing that testing has validated their potential.

Frequently Asked Questions

What types of connectors can be tested?

Eurolabs laboratory service supports a wide range of connector types, including power connectors, I/O connectors, and connectors for specific industries (e.g., aerospace, medical).

How do you simulate real-world conditions in the laboratory?

Our expert technicians use specialized equipment to simulate various stress tests, such as electrical loads, vibration, thermal cycling, and corrosion.

What types of testing are available?

Eurolab offers a range of testing services, including static and dynamic testing, thermal cycling, humidity testing, and environmental testing.

How long does the testing process take?

The duration of testing depends on the type of connector, test conditions, and client requirements. Our expert technicians work closely with clients to ensure that tests are completed efficiently and effectively.

What kind of reporting is provided after testing?

Eurolab provides comprehensive test reports detailing the performance and lifespan of power connector contacts under different scenarios. Reports include detailed analysis, recommendations for improvement, and data visualization tools.

Can Eurolab assist with design optimization?

Yes! Our expert technicians can help optimize designs based on test data, ensuring that your products meet industry standards and regulations.

Are the results of testing confidential?

Absolutely! All test data and reports are treated as confidential and remain the property of the client.

Conclusion

Testing the Durability of Contacts in Power Connectors is a crucial laboratory service provided by Eurolab that helps businesses ensure the reliability and performance of their electrical components. By identifying potential issues early on, companies can prevent costly downtime, improve product reliability, and stay ahead of regulatory requirements.

Dont let faulty power connector contacts compromise your businesss reputation or bottom line. Contact us today to learn more about our laboratory service and how it can benefit your company!