Testing for Contact Resistance in Printed Circuit Boards

The Crucial Role of Contact Resistance Testing in Printed Circuit Boards Why Your Business Needs Eurolabs Expertise

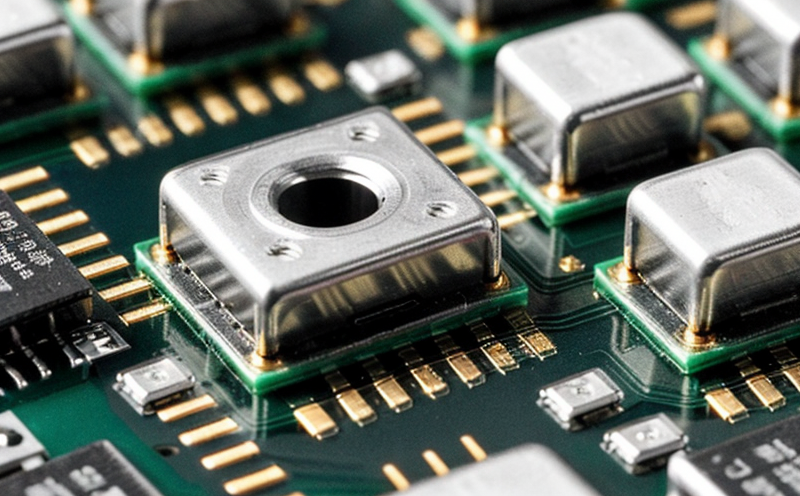

In the world of electronics and manufacturing, the reliability and performance of printed circuit boards (PCBs) are crucial factors that determine the success of a product. However, even with the most advanced design and manufacturing techniques, PCBs can still be prone to defects and malfunctions due to inadequate contact resistance. This is where Eurolabs testing for contact resistance in printed circuit boards comes into play a laboratory service that ensures the optimal performance and lifespan of your products.

What is Contact Resistance Testing?

Contact resistance, also known as contact resistance voltage (CRV), refers to the opposition to current flow between two conductive surfaces or contacts on a PCB. Its a critical parameter that affects the overall performance, reliability, and longevity of electronic devices. During production, small defects or imperfections in the PCB manufacturing process can lead to increased contact resistance, causing issues such as

Reduced device lifespan

Decreased performance and efficiency

Increased power consumption

Malfunctions and failures

Why is Contact Resistance Testing Essential for Businesses?

In todays competitive market, businesses cannot afford to compromise on product quality or reliability. A single defect or malfunction can result in costly rework, repair, or even replacement of entire PCBs. By investing in contact resistance testing, companies can

Ensure optimal performance and efficiency By identifying and addressing potential issues early on, you can prevent problems that might arise during production or usage.

Reduce costs associated with rework and repair Minimize the financial burden of repairing or replacing faulty PCBs by detecting defects before they become major issues.

Improve product lifespan Extend the life expectancy of your products by identifying potential weaknesses and taking corrective action to prevent premature failures.

Enhance customer satisfaction By providing high-quality products that meet performance expectations, you can build trust with customers and maintain a strong reputation in the market.

Benefits of Testing for Contact Resistance in Printed Circuit Boards

Early defect detection Identify potential issues before they become major problems, ensuring your PCBs meet quality standards.

Improved manufacturing yields Reduce waste and optimize production processes by detecting defects early on.

Increased product lifespan Extend the life expectancy of your products by addressing potential weaknesses.

Enhanced customer satisfaction Meet performance expectations and maintain a strong reputation in the market.

Reduced costs associated with rework and repair Minimize financial burdens by identifying and addressing issues before they become major problems.

How Does Eurolabs Contact Resistance Testing Service Work?

Eurolabs expert team uses state-of-the-art equipment to conduct thorough testing for contact resistance in printed circuit boards. Our comprehensive service includes

Sample preparation We receive your PCB samples, clean and prepare them for testing.

Testing Our experienced technicians use advanced instruments to measure the contact resistance of each sample.

Data analysis We analyze the test results to identify potential issues or areas for improvement.

Reporting and recommendations Our expert team provides a detailed report outlining the findings and offering suggestions for corrective action.

QA Frequently Asked Questions About Contact Resistance Testing

What types of PCBs can be tested?

Our testing service is suitable for a wide range of PCB applications, including but not limited to

Automotive electronics

Aerospace components

Medical devices

Industrial control systems

How do I prepare my samples for testing?

Please ensure that your PCB samples are clean, dry, and free from any debris or contaminants.

What is the typical turnaround time for contact resistance testing?

Our standard turnaround time is 5-7 business days, but this may vary depending on the complexity of the test and the workload at the time.

Can I get a copy of my test report in multiple formats (e.g., PDF, Word)?

Yes, we can provide your test report in various formats to suit your needs.

Conclusion

In todays fast-paced manufacturing environment, its essential for businesses to invest in quality control measures that ensure optimal product performance and reliability. Eurolabs testing for contact resistance in printed circuit boards is a crucial service that helps companies identify potential issues early on, reducing the risk of costly rework, repair, or replacement. By partnering with Eurolab, you can trust that your PCBs meet the highest standards of quality and performance.

Dont compromise on product reliability choose Eurolab for expert contact resistance testing services and take the first step towards ensuring the success of your products.