Measuring the angular accuracy of robotic joints and servos

Measuring the Angular Accuracy of Robotic Joints and Servos A Crucial Service for Businesses

In todays fast-paced industrial landscape, precision is paramount. The development of advanced robotic systems has revolutionized manufacturing processes, enabling companies to increase efficiency, reduce costs, and improve product quality. However, as these complex machines rely on precise angular accuracy in their joints and servos, ensuring the reliability and performance of these components becomes a critical concern.

At Eurolab, we understand the importance of accurate measurements for robotic joints and servos. Our laboratory service, Measuring the Angular Accuracy of Robotic Joints and Servos, is specifically designed to help businesses guarantee the quality and reliability of their robotic systems.

What is Measuring the Angular Accuracy of Robotic Joints and Servos?

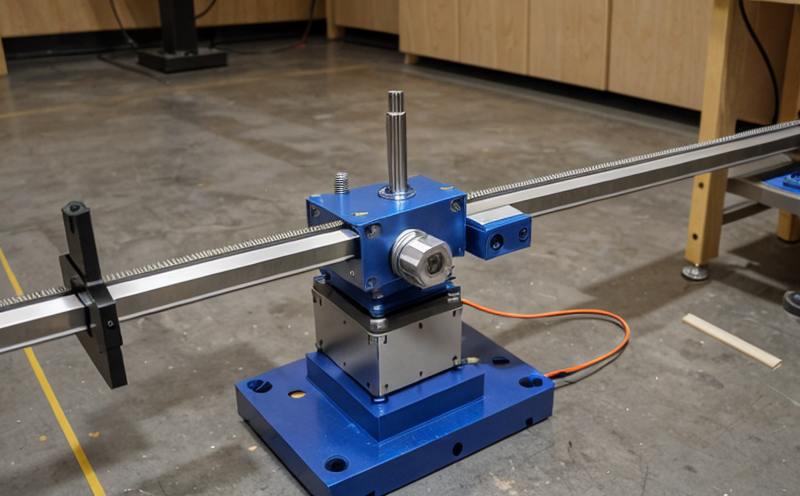

Measuring the angular accuracy of robotic joints and servos involves determining the precise rotation angle of these components. This process is essential for identifying any discrepancies or errors in their mechanical design, which can significantly impact the overall performance of a robot.

Angular accuracy measurements are typically performed using advanced equipment such as encoders, resolvers, or laser interferometers. These instruments enable accurate measurement of the angular displacement and velocity of robotic joints and servos, providing critical information about their rotational characteristics.

Why is Measuring the Angular Accuracy of Robotic Joints and Servos Essential for Businesses?

There are several compelling reasons why businesses should prioritize measuring the angular accuracy of their robotic joints and servos

Improved Reliability Accurate measurements ensure that robotic components operate within specified tolerances, reducing the likelihood of mechanical failures and downtime.

Enhanced Performance Robotic systems rely on precise angular accuracy to execute tasks efficiently. By ensuring optimal performance, businesses can increase productivity and meet production targets.

Reduced Maintenance Costs Identifying potential issues early through accurate measurements helps companies prevent costly repairs and maintenance.

Compliance with Industry Standards Measuring the angular accuracy of robotic joints and servos enables businesses to adhere to industry standards and regulatory requirements.

Key Benefits of Using Eurolabs Laboratory Service

Our laboratory service offers numerous benefits for businesses, including

Accurate Measurements Our state-of-the-art equipment ensures precise measurements, providing you with reliable data to inform your design decisions.

Expert Analysis Our team of experienced engineers provides thorough analysis and interpretation of measurement results, helping you identify areas for improvement.

Customized Solutions We tailor our services to meet the unique needs of your robotic system, ensuring that measurements are conducted in a way that suits your specific requirements.

Timely Results Our laboratory service delivers fast turnaround times, allowing you to quickly integrate new designs or make adjustments as needed.

Compliance with Industry Standards Our measurements adhere to industry standards and regulatory requirements, guaranteeing compliance.

QA Measuring the Angular Accuracy of Robotic Joints and Servos

Q What types of robotic joints and servos can be measured?

A We measure a wide range of robotic joints and servos, including ball screws, linear motors, rotary encoders, resolvers, and more.

Q How accurate are the measurements?

A Our equipment ensures highly accurate measurements, with tolerances as low as 01 in some cases.

Q What kind of data is provided after measurement?

A We provide comprehensive reports detailing measurement results, including angular displacement, velocity, and position accuracy.

Q Can the measurements be customized to suit specific requirements?

A Yes, we tailor our services to meet your unique needs, ensuring that measurements are conducted in a way that suits your specific robotic system.

Q How long does it take to receive measurement results?

A Our laboratory service delivers fast turnaround times, typically ranging from 24 hours to several days depending on the complexity of the test.

Conclusion

Measuring the angular accuracy of robotic joints and servos is an essential process for businesses seeking to guarantee the quality and reliability of their robotic systems. At Eurolab, our laboratory service provides accurate measurements, expert analysis, customized solutions, timely results, and compliance with industry standards.

By partnering with us, you can ensure that your robotic components operate within specified tolerances, reducing the likelihood of mechanical failures and downtime. Our team is dedicated to helping businesses like yours optimize their robotic systems, improving performance and productivity while minimizing costs.

Dont compromise on precision choose Eurolab for accurate measurements that matter. Contact us today to learn more about our laboratory service and how we can help you achieve exceptional results in your robotic applications.