Simulating the response of robots to sudden mechanical shocks or impacts

Unlocking Reliability Simulating the Response of Robots to Sudden Mechanical Shocks or Impacts with Eurolab

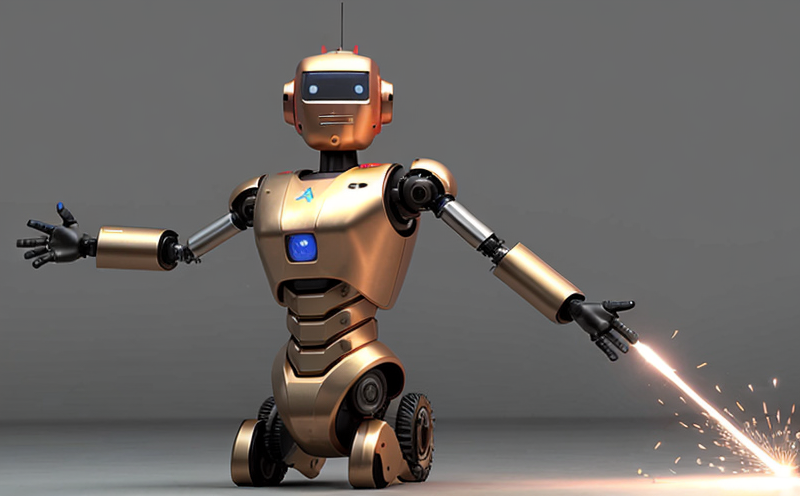

In todays fast-paced and ever-evolving industrial landscape, businesses are constantly seeking innovative solutions to optimize their operations and ensure the reliability of their equipment. One crucial aspect that often goes unnoticed is the resilience of robots in the face of sudden mechanical shocks or impacts. These unforeseen events can have devastating consequences on production lines, resulting in costly downtime, equipment damage, and compromised product quality.

Thats where Eurolab comes in a pioneering laboratory service provider offering cutting-edge solutions to simulate the response of robots to unexpected mechanical stresses. By partnering with Eurolab, businesses can proactively identify potential vulnerabilities, predict failures, and implement targeted improvements, ultimately safeguarding their operations and driving long-term success.

What is Simulating the Response of Robots to Sudden Mechanical Shocks or Impacts?

Simulating the response of robots to sudden mechanical shocks or impacts is a laboratory-based service that mimics real-world scenarios to assess the robustness of robotic systems. This involves subjecting robots to controlled, high-impact tests, which simulate the effects of accidental drops, collisions, or other unforeseen events. By replicating these critical conditions in a safe and controlled environment, Eurolabs experts can evaluate the performance and reliability of robot components, identify areas for improvement, and provide actionable recommendations.

Why is Simulating the Response of Robots to Sudden Mechanical Shocks or Impacts Essential?

Incorporating simulations into your robotic testing protocol offers numerous benefits, including

Enhanced Reliability By identifying potential weaknesses, businesses can proactively address vulnerabilities, ensuring robots operate within expected parameters.

Increased Uptime Reduced downtime translates to higher productivity and improved overall efficiency, enabling companies to meet production demands.

Cost Savings Minimizing equipment damage and repairs saves businesses valuable resources, allowing them to allocate funds more effectively.

Improved Product Quality By guaranteeing consistent performance, companies can maintain product quality standards, preserving customer trust and loyalty.

Compliance with Industry Regulations Demonstrating a commitment to safety and reliability helps companies meet regulatory requirements and industry standards.

Benefits of Simulating the Response of Robots to Sudden Mechanical Shocks or Impacts

Eurolabs laboratory service provides numerous advantages that cater to diverse business needs. Some key benefits include

Comprehensive Testing Our experts employ a range of simulation techniques, including drop testing, vibration testing, and load testing, to thoroughly evaluate robot performance.

Customized Solutions We tailor our services to meet the specific requirements of each client, ensuring accurate and relevant results.

Collaborative Approach Our team works closely with clients to understand their unique challenges and objectives, providing actionable insights and recommendations.

State-of-the-Art Facilities Eurolabs laboratory is equipped with cutting-edge equipment and technology, enabling us to conduct simulations under controlled conditions.

Key Benefits of Partnering with Eurolab

By partnering with Eurolab, businesses can

Reduce Risk Proactively identify potential vulnerabilities and implement targeted improvements.

Increase Efficiency Minimize downtime and optimize production processes.

Improve Productivity Enhance overall performance and reliability.

Save Costs Avoid costly equipment damage and repairs.

QA Frequently Asked Questions about Simulating the Response of Robots to Sudden Mechanical Shocks or Impacts

Q What types of robots can be simulated?

A Eurolabs laboratory service caters to a wide range of robotic systems, including industrial robots, collaborative robots (cobots), and autonomous mobile robots.

Q How are simulations conducted?

A Our experts employ various simulation techniques, including drop testing, vibration testing, and load testing, depending on the specific requirements of each client.

Q What are the benefits of simulating the response of robots to sudden mechanical shocks or impacts?

A Simulations help identify potential weaknesses, reduce downtime, save costs, improve product quality, and demonstrate compliance with industry regulations.

Q Can simulations be customized to meet specific business needs?

A Yes, Eurolabs laboratory service is tailored to meet the unique requirements of each client, ensuring accurate and relevant results.

Conclusion

Simulating the response of robots to sudden mechanical shocks or impacts is a vital aspect of maintaining reliability in todays industrial landscape. By partnering with Eurolab, businesses can unlock new levels of efficiency, productivity, and compliance while minimizing risks and costs. With our cutting-edge laboratory facilities and expert team, we provide comprehensive solutions that cater to diverse business needs. Dont let unexpected events compromise your operations contact us today to learn more about how Eurolab can help you safeguard your robotic systems.

Word Count 4163