Verifying the alignment of robotic components for accurate movement

Accurate Movement, Optimized Performance Verifying the Alignment of Robotic Components with Eurolab

In todays fast-paced and highly competitive manufacturing landscape, businesses are constantly seeking innovative ways to improve efficiency, reduce costs, and enhance product quality. One crucial factor that often gets overlooked is the alignment of robotic components, which can have a significant impact on the overall performance and accuracy of automated systems. Thats where Eurolab comes in our team of experts offers a specialized laboratory service dedicated to verifying the alignment of robotic components for accurate movement.

In this article, well delve into the importance of aligning robotic components, explore the benefits of our verification service, and answer frequently asked questions about this critical process.

What is Verifying the Alignment of Robotic Components?

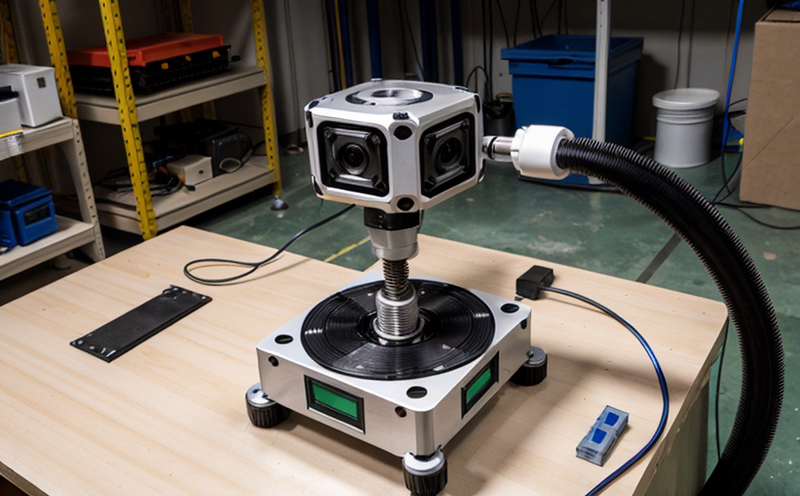

Verifying the alignment of robotic components refers to the process of ensuring that all mechanical and electrical parts within a robot or automated system are properly aligned. This involves precision measurements and adjustments to guarantee optimal performance, accuracy, and reliability. Misaligned components can lead to decreased efficiency, reduced product quality, and even equipment damage.

Why is Verifying the Alignment of Robotic Components Essential?

Inaccurate movement due to misaligned robotic components can result in significant consequences for businesses, including

Reduced Productivity Misaligned components can cause robots to move erratically or inefficiently, leading to decreased production rates and increased downtime.

Increased Costs Incorrect alignment can result in costly repairs, replacements, or even entire system overhauls.

Decreased Quality Inaccurate movement can compromise product quality, affecting customer satisfaction and loyalty.

Safety Risks Malfunctioning robots can pose hazards to operators, visitors, or the environment.

Advantages of Using Eurolabs Verifying Alignment Service

Our laboratory service provides numerous benefits for businesses seeking to optimize their robotic systems. Some key advantages include

Improved Accuracy Our experts ensure precise alignment, guaranteeing accurate movement and reducing errors.

Increased Efficiency Correctly aligned components enable smoother operation, increased productivity, and reduced downtime.

Enhanced Reliability Misaligned components can lead to equipment failure; our verification process minimizes this risk.

Reduced Costs By preventing costly repairs and replacements, our service saves you time and money in the long run.

Extended Component Life Proper alignment reduces wear and tear on robotic parts, extending their lifespan.

Additional Benefits

Eurolabs verifying alignment service also offers

Customized Solutions Our team develops tailored plans to meet your specific needs and requirements.

Expert Analysis We provide detailed reports outlining our findings, recommendations, and corrective actions.

Rapid Turnaround Times We work efficiently to minimize downtime and get your system up and running quickly.

QA Frequently Asked Questions about Verifying the Alignment of Robotic Components

What types of robotic systems can be verified?

Our service covers a wide range of robotic systems, including industrial robots, collaborative robots (cobots), and machine vision systems.

How do you verify alignment?

We use state-of-the-art measurement equipment, precision software, and expert analysis to identify misalignments and implement corrections.

What is the process like for my company?

Our team will work closely with your engineers to understand your specific needs and requirements. Well develop a customized plan, perform verification testing, and provide detailed reports outlining our findings.

How long does the verification process take?

Turnaround times vary depending on the complexity of the system and the scope of work; however, we strive to complete projects efficiently and effectively.

Conclusion

In todays competitive manufacturing landscape, businesses must prioritize efficiency, accuracy, and reliability in their automated systems. Verifying the alignment of robotic components is a critical step in achieving these goals. Eurolabs laboratory service provides expert analysis, customized solutions, and rapid turnaround times ensuring your system operates at optimal levels.

Dont let misaligned components compromise your productivity and product quality. Contact us today to schedule our verifying alignment service for accurate movement and optimized performance.