Measuring thermal stability of coatings in high-altitude conditions

Measuring Thermal Stability of Coatings in High-Altitude Conditions A Crucial Service for Businesses

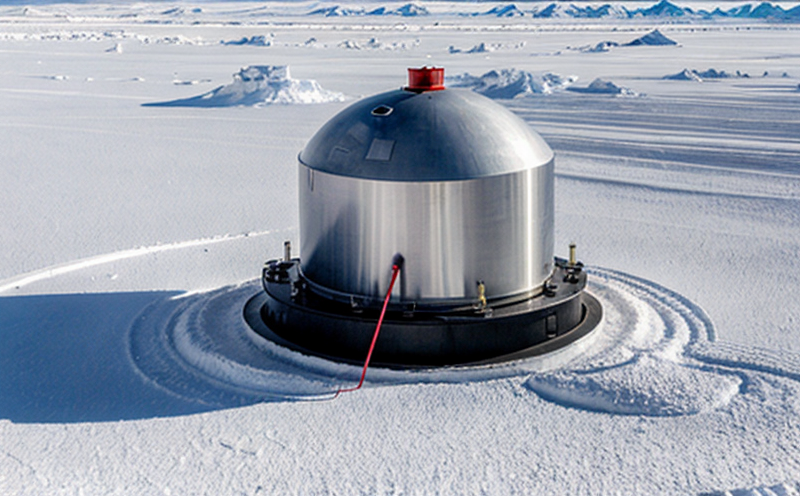

As the demand for high-performance coatings continues to rise, manufacturers and researchers are facing a pressing challenge ensuring their products can withstand the harsh conditions found at high altitudes. Extreme temperatures, low air pressure, and intense radiation can all take a toll on coatings, leading to degradation, cracking, and even failure. In this article, well explore the importance of measuring thermal stability in high-altitude conditions and how Eurolabs laboratory service can help businesses stay ahead of the curve.

Why Measuring Thermal Stability Matters

High-altitude environments pose unique challenges for coatings due to their extreme temperature fluctuations. At high altitudes, temperatures can drop dramatically at night, while rising rapidly during the day. This thermal cycling can cause coatings to degrade prematurely, compromising their performance and lifespan. Moreover, the thin air at high elevations can accelerate radiation damage, leading to a reduction in coating durability.

To mitigate these risks, businesses need to ensure their coatings can withstand the thermal stresses associated with high-altitude conditions. Measuring thermal stability is essential for predicting how well a coating will perform under real-world conditions. By understanding a coatings thermal limitations, manufacturers can

Extend Coating Lifespan By identifying potential thermal degradation points, companies can develop coatings that last longer and require less maintenance.

Improve Performance Thermal stability testing enables the development of coatings with optimized performance characteristics for high-altitude applications.

Reduce Warranty Claims By understanding a coatings limitations, manufacturers can set realistic expectations with customers, reducing warranty claims and associated costs.

Key Benefits of Measuring Thermal Stability

Here are the key benefits of measuring thermal stability in high-altitude conditions

Improved Coating Durability Understanding a coatings thermal limitations allows for the development of coatings that can withstand extreme temperature fluctuations.

Enhanced Performance By optimizing coatings for high-altitude environments, businesses can improve overall performance and efficiency.

Reduced Maintenance Costs Extended coating lifespan reduces maintenance needs, saving businesses time and money.

Increased Customer Confidence Manufacturers can provide customers with accurate information about a coatings performance capabilities, building trust and loyalty.

Compliance with Regulations Measuring thermal stability helps companies meet industry standards and regulations for high-altitude applications.

What is Involved in Measuring Thermal Stability?

Measuring thermal stability involves subjecting coatings to a range of temperature conditions that simulate those found at high altitudes. This process typically includes

Thermal Cycling Coatings are subjected to repeated cycles of heating and cooling, mimicking the temperature fluctuations experienced at high altitudes.

High-Temperature Exposure Coatings are exposed to extreme temperatures (up to 200C/392F) for extended periods, simulating the thermal stresses associated with high-altitude conditions.

Low-Temperature Exposure Coatings are subjected to low temperatures (-50C/-58F), mimicking the cold temperatures found at high altitudes.

Eurolabs Laboratory Service

At Eurolab, our team of experts provides comprehensive laboratory services for measuring thermal stability in high-altitude conditions. Our state-of-the-art facilities and cutting-edge equipment enable us to simulate a wide range of temperature conditions, from -50C/-58F to 200C/392F.

QA Frequently Asked Questions

What types of coatings can be tested?

Eurolabs laboratory service is suitable for various coating types, including but not limited to

Paints and varnishes

Protective coatings (e.g., polyurethane, epoxy)

Aerospace coatings (e.g., aluminized, ceramic-based)

How long does the testing process take?

Testing times vary depending on the coating type and specific testing requirements.

What kind of data can I expect from Eurolabs laboratory service?

Our expert team provides detailed reports outlining thermal stability performance, including

Coating degradation rates

Thermal cycling effects

Radiation damage

Conclusion

Measuring thermal stability in high-altitude conditions is a critical step in ensuring coatings perform optimally and last longer. By understanding a coatings thermal limitations, manufacturers can develop products that meet the demands of extreme environments. Eurolabs laboratory service provides businesses with comprehensive testing capabilities, empowering them to make informed decisions about their coatings performance.

Dont compromise on coating quality choose Eurolab for expert thermal stability testing and unlock the full potential of your high-performance coatings.