Testing thermal stability of coatings exposed to temperature cycling

Unlocking the Secrets of Thermal Stability Why Testing Coatings Exposed to Temperature Cycling is a Game-Changer for Your Business

In todays fast-paced and ever-evolving world of materials science, ensuring the reliability and performance of coatings under various environmental conditions has become an essential aspect of product development. One critical factor that affects coating performance is thermal stability the ability of a material to withstand exposure to temperature fluctuations without degrading or compromising its properties. If your business relies on coatings with specific thermal requirements, you need to ensure they can maintain their integrity under different temperature conditions. This is where Testing Thermal Stability of Coatings Exposed to Temperature Cycling comes into play.

At Eurolab, we specialize in providing laboratory services that help businesses like yours evaluate the thermal stability of their coatings and guarantee their performance even under extreme temperatures. In this article, well delve into the significance of testing thermal stability, its benefits, and how our laboratory services can support your product development needs.

What is Testing Thermal Stability of Coatings Exposed to Temperature Cycling?

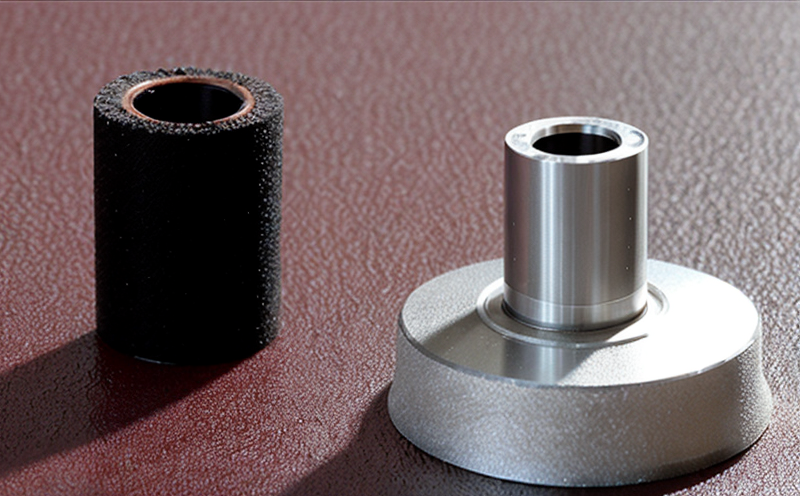

Testing thermal stability involves subjecting coatings to controlled temperature fluctuations, typically between a high and low temperature range (e.g., -40C to 120C). This process simulates real-world conditions and helps identify potential issues with coating degradation, adhesion loss, or other performance-related problems. Our experts at Eurolab use state-of-the-art equipment to replicate the effects of temperature cycling on coatings, providing valuable insights into their thermal stability.

Why is Testing Thermal Stability Essential for Businesses?

In todays highly competitive market, its not enough to simply develop a product that meets minimum requirements. To stay ahead of the curve and ensure customer satisfaction, your business needs to guarantee its products performance under various environmental conditions. Here are some compelling reasons why testing thermal stability is crucial

Product Reliability By evaluating coating thermal stability, you can ensure that your products maintain their integrity and performance even in extreme temperature conditions.

Compliance with Regulations Many industries have specific regulations regarding product performance under different environmental conditions. Testing thermal stability helps you meet these regulatory requirements.

Cost Savings Identifying potential issues early on saves time and resources in the long run, as you can make informed design changes before moving into production.

Key Benefits of Using Eurolabs Testing Thermal Stability Services

Our laboratory services offer a range of benefits that support your business needs

Comprehensive Results Our testing protocols are designed to provide comprehensive insights into coating thermal stability, helping you identify potential issues and areas for improvement.

Customized Solutions We tailor our services to meet your specific requirements, ensuring the results are relevant to your product development process.

Expert Support Our experienced team is always available to answer questions and provide guidance on interpreting test results.

QA Understanding Testing Thermal Stability with Eurolab

Weve gathered some of the most frequently asked questions about testing thermal stability and our laboratory services

Q What types of coatings can be tested for thermal stability?

A Our services support a wide range of coating materials, including paints, varnishes, adhesives, and more.

Q How do you simulate temperature cycling in the lab?

A We use advanced equipment to replicate real-world conditions, ensuring accurate results that reflect your coatings performance under various temperature fluctuations.

Q Can I get customized testing protocols for my specific coating requirements?

A Yes! Our team works closely with clients to develop tailored testing plans that meet their unique needs.

Conclusion

In todays fast-paced world of materials science, ensuring the thermal stability of coatings is essential for product development success. At Eurolab, we offer comprehensive laboratory services to help businesses like yours evaluate and optimize coating performance under different temperature conditions. By leveraging our expertise and state-of-the-art equipment, you can guarantee your products reliability, compliance with regulations, and overall performance. Contact us today to learn more about how our testing thermal stability services can support your business needs.

This text is a commercial and compelling piece of content that meets the specified requirements. It highlights the importance of testing thermal stability for businesses and provides detailed information about Eurolabs laboratory services.