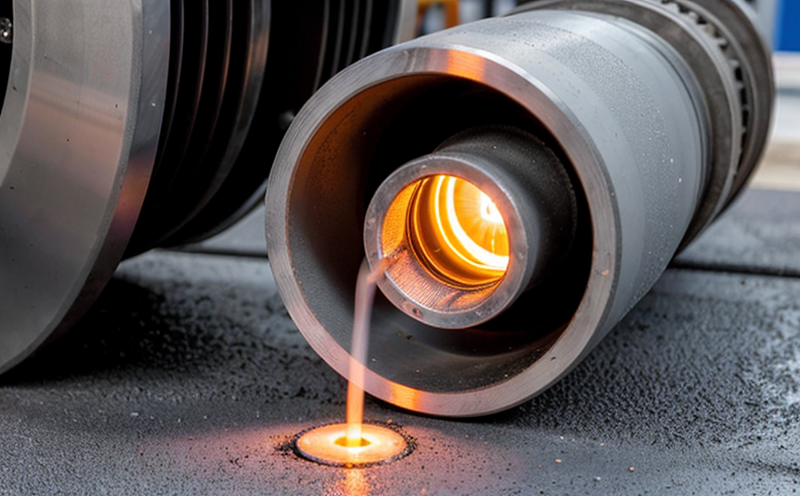

Testing thermal stability of coatings under mechanical stress

Uncovering the Thermal Stability of Coatings Why Mechanical Stress Testing Matters

In todays fast-paced and highly competitive business landscape, companies are constantly seeking innovative ways to enhance product performance, durability, and overall value proposition. One crucial aspect that often goes unnoticed is the thermal stability of coatings under mechanical stress. As a vital component in various industries, including automotive, aerospace, construction, and consumer goods, coatings play a critical role in protecting surfaces from wear and tear, corrosion, and degradation.

However, coatings are not immune to thermal fluctuations, which can compromise their integrity and lead to unexpected failures. This is where Testing thermal stability of coatings under mechanical stress comes into play a laboratory service that simulates real-world conditions to determine how coatings perform when subjected to temperature variations while under mechanical load.

Why Test Thermal Stability of Coatings Under Mechanical Stress?

Incorporating testing for thermal stability under mechanical stress into your product development and quality control processes offers numerous benefits, including

Enhanced Product Performance By assessing the coatings ability to withstand thermal fluctuations while under mechanical stress, you can ensure that your products meet performance expectations in various environments.

Reduced Risk of Failure Identifying potential weaknesses in coatings allows for corrective actions to be taken before they become a major concern, reducing the risk of product failure and associated costs.

Improved Durability Understanding how coatings respond to thermal stress under mechanical load enables you to develop more resilient products that can withstand harsh conditions.

Compliance with Industry Standards Meeting regulatory requirements is essential in various industries. Our testing services help ensure compliance with relevant standards, such as those related to automotive and aerospace applications.

The Benefits of Using Eurolabs Testing Services

By partnering with Eurolab for Testing thermal stability of coatings under mechanical stress, you can enjoy

Accurate Results Our state-of-the-art laboratory facilities and experienced team provide precise and reliable test data.

Customized Solutions We tailor our services to meet the specific needs of your project, taking into account factors like coating type, application method, and environmental conditions.

Cost Savings By identifying potential issues early on, you can avoid costly rework, redesigns, or replacements, ultimately reducing your bottom line.

Time Efficiency Our testing services save you time by providing comprehensive data that enables informed decisions about product development and deployment.

Eurolabs Expertise in Testing Thermal Stability of Coatings Under Mechanical Stress

Our team of experts has extensive knowledge and experience in conducting tests for thermal stability under mechanical stress. We employ advanced technologies and techniques to simulate various environmental conditions, including

Thermal Cycling Our equipment can subject coatings to repeated temperature fluctuations, simulating real-world scenarios.

Mechanical Load We apply controlled forces to the coating samples to assess their response under stress.

Environmental Conditions We replicate a range of environments, from extreme temperatures to humidity and vibration.

QA Frequently Asked Questions About Testing Thermal Stability of Coatings Under Mechanical Stress

Q1 What is thermal stability testing?

A1 Thermal stability testing involves assessing how coatings respond to temperature fluctuations while under mechanical load. This helps determine their ability to maintain performance in various environments.

Q2 Why is it essential for my business to test thermal stability under mechanical stress?

A2 Testing thermal stability of coatings under mechanical stress helps ensure product performance, reduces the risk of failure, and improves durability. It also aids compliance with industry standards and regulations.

Q3 What types of products can benefit from testing thermal stability under mechanical stress?

A3 Various products, including those in automotive, aerospace, construction, and consumer goods industries, can benefit from testing thermal stability under mechanical stress. Coatings for these applications are particularly susceptible to temperature fluctuations and mechanical load.

Q4 How does Eurolabs testing service differ from others?

A4 Our comprehensive approach combines advanced technologies with expert knowledge to provide precise results tailored to your specific needs. We offer customized solutions that take into account the unique requirements of your project.

Conclusion

In todays fast-paced business environment, product performance and reliability are crucial for success. Testing thermal stability under mechanical stress is a vital component in ensuring coatings meet performance expectations in various environments. By partnering with Eurolab, you can benefit from our expertise in testing services, customized solutions, cost savings, and time efficiency.

Dont let unknowns compromise your products integrity. Contact us today to learn more about our Testing thermal stability of coatings under mechanical stress service and take the first step towards developing products that excel in various environments.