Measuring torque variation across robotic joints during dynamic movements

Measuring Torque Variation Across Robotic Joints During Dynamic Movements A Crucial Service for Industry Leaders

As the world of robotics continues to advance at an unprecedented pace, companies across various industries are leveraging these intelligent machines to optimize production, enhance efficiency, and improve product quality. However, with great power comes great responsibility ensuring that robotic joints perform within predetermined parameters is crucial to maintain peak performance and minimize downtime.

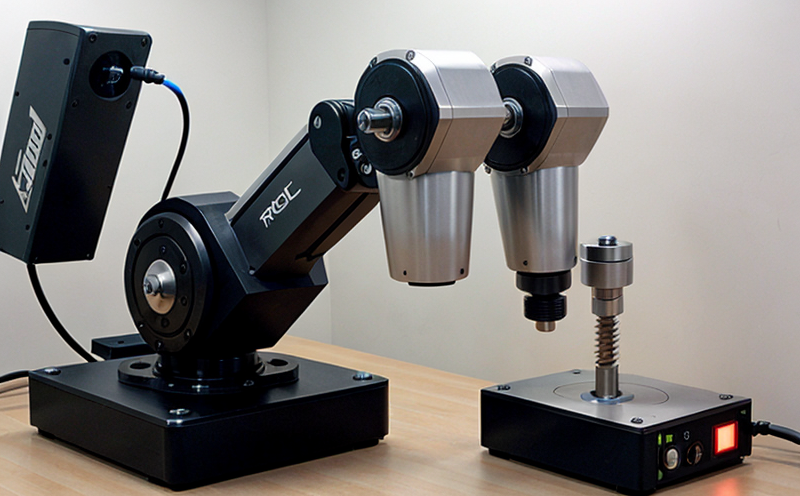

At Eurolab, we understand the significance of precision engineering in robotics. Our team of experts offers a cutting-edge laboratory service that measures torque variation across robotic joints during dynamic movements. This innovative solution helps businesses optimize their robotic systems, ensuring they operate at maximum efficiency and reliability.

Why Measuring Torque Variation Across Robotic Joints During Dynamic Movements Matters

In todays competitive landscape, companies must continually innovate to stay ahead of the curve. With increasing demands for precision and speed, manufacturers rely heavily on robotic systems to streamline production processes. However, these machines are only as good as their weakest link and that often lies in the joint dynamics.

Measuring torque variation across robotic joints during dynamic movements is essential because it directly impacts

Product Quality Unpredictable joint behavior can lead to inconsistent product quality, resulting in costly rework or even complete rejection.

Downtime Reduction Preventing mechanical failures by identifying and addressing issues proactively minimizes the likelihood of unexpected shutdowns.

Energy Efficiency Optimizing robotic joints for reduced energy consumption not only saves companies money but also helps minimize their carbon footprint.

Increased Productivity By ensuring that robotic systems operate within predetermined parameters, businesses can boost production rates without compromising quality.

The Advantages of Using Eurolabs Measuring Torque Variation Service

Our laboratory service offers numerous benefits to industry leaders, including

Benefits for Manufacturers

Improved Joint Performance Identify and address torque variation issues, ensuring that robotic joints operate smoothly and efficiently.

Enhanced Reliability Reduce the risk of mechanical failures by detecting potential problems before they occur.

Increased Productivity Optimize production processes by leveraging data-driven insights to fine-tune robotic system performance.

Benefits for Robotics Developers

Informed Design Decisions Use our laboratory services to validate and improve joint design, reducing development time and costs.

Real-World Testing Validate robotic systems in a controlled environment, ensuring they meet performance expectations.

Competitive Advantage Differentiate your products by emphasizing the reliability and efficiency of your robotic joints.

Benefits for Research Institutions

Advancing Robotics Technology Collaborate with Eurolab to advance joint design and optimization techniques, pushing the boundaries of robotics research.

Access to Expertise Leverage our teams extensive knowledge and experience in robotic system testing and analysis.

Cutting-Edge Infrastructure Utilize our state-of-the-art laboratory facilities to conduct experiments and gather data.

QA Frequently Asked Questions

Q What is Measuring Torque Variation Across Robotic Joints During Dynamic Movements?

A This laboratory service involves using advanced equipment to measure the torque applied to robotic joints as they move through a range of motions. The goal is to identify any variations in torque, which can indicate potential issues with joint performance or mechanical design.

Q What types of robots can be tested using this service?

A Our laboratory services cater to various types of industrial robots, including those used for assembly, welding, and material handling. We also support testing of humanoid robots and other specialized robotic systems.

Q How do I prepare my robotic system for testing?

A Before arriving at our facility, ensure that your robot is in good working condition and has been properly calibrated. Provide us with detailed specifications and documentation to facilitate a smooth testing process.

Q What are the benefits of outsourcing this service versus conducting it in-house?

A By partnering with Eurolab, you can tap into our expertise and specialized equipment without investing heavily in infrastructure or training personnel. Our team will handle data analysis and provide actionable insights to inform your decision-making.

Conclusion

Measuring torque variation across robotic joints during dynamic movements is a critical aspect of ensuring peak performance and reliability in industrial robotics. At Eurolab, we offer a comprehensive laboratory service that empowers businesses to optimize their robotic systems, minimizing downtime and maximizing productivity.

By choosing our expert services, you can

Optimize Joint Performance Identify and address torque variation issues for improved efficiency.

Reduce Downtime Prevent mechanical failures by detecting potential problems proactively.

Boost Productivity Leverage data-driven insights to fine-tune production processes.

Dont compromise on the performance of your robotic systems. Trust Eurolabs expertise to ensure that your machines operate at maximum capacity, enabling you to stay ahead in a competitive marketplace.