Validation of robotic joint torque in high-speed manufacturing systems

Validation of Robotic Joint Torque in High-Speed Manufacturing Systems Ensuring Precision and Efficiency

In todays fast-paced manufacturing landscape, businesses are under increasing pressure to deliver high-quality products quickly and efficiently while minimizing costs. To achieve this goal, companies are increasingly relying on robotic automation systems to streamline production processes. However, as the speed and complexity of these systems increase, so do the risks of errors and inefficiencies. This is where Validation of Robotic Joint Torque in High-Speed Manufacturing Systems comes into play a critical laboratory service provided by Eurolab that ensures the precision and accuracy of robotic joints in high-speed manufacturing systems.

What is Validation of Robotic Joint Torque?

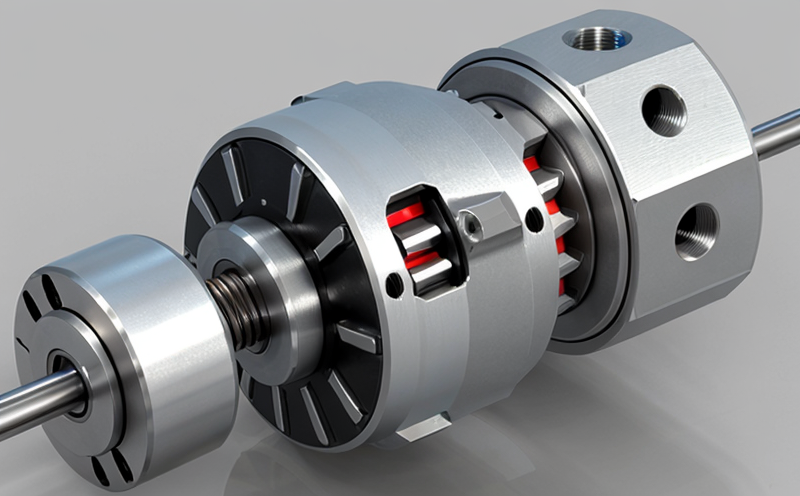

Validation of Robotic Joint Torque refers to the process of testing and verifying the torque output of individual robotic joints, particularly those involved in high-speed applications. This involves measuring the actual torque values generated by each joint under various conditions, including speed, load, and temperature. The goal is to ensure that the joints are functioning within specified tolerances, thereby preventing errors, reducing wear and tear, and optimizing system performance.

Why is Validation of Robotic Joint Torque Essential for Businesses?

In todays competitive manufacturing environment, companies cannot afford to compromise on quality or efficiency. A validated robotic joint torque ensures

Precision Accurate torque measurements ensure that joints operate within specified tolerances, reducing the risk of errors and improving overall system performance.

Efficiency Validated joints minimize downtime, reduce energy consumption, and optimize production processes, leading to increased productivity and competitiveness.

Reliability By detecting potential issues early on, businesses can prevent costly repairs, replacements, or even entire system failures.

Compliance Validation of robotic joint torque ensures adherence to industry standards and regulations, minimizing the risk of non-compliance and associated fines.

Benefits of Validation of Robotic Joint Torque in High-Speed Manufacturing Systems

Validation of robotic joint torque offers numerous benefits for businesses involved in high-speed manufacturing systems. Some key advantages include

Advantages for Manufacturers

Improved Product Quality Accurate torque measurements ensure that joints operate within specified tolerances, leading to improved product quality and reduced defects.

Increased Efficiency Validated joints minimize downtime, reduce energy consumption, and optimize production processes, leading to increased productivity and competitiveness.

Enhanced Reliability By detecting potential issues early on, manufacturers can prevent costly repairs, replacements, or even entire system failures.

Compliance with Industry Standards Validation of robotic joint torque ensures adherence to industry standards and regulations, minimizing the risk of non-compliance and associated fines.

Advantages for End-Users

Improved System Performance Validated joints ensure that systems operate within specified tolerances, leading to improved performance and reduced errors.

Increased Productivity By optimizing production processes, end-users can increase productivity and competitiveness in the market.

Reduced Maintenance Costs Accurate torque measurements enable early detection of potential issues, reducing maintenance costs and extending equipment lifespan.

Enhanced Customer Satisfaction Validated joints lead to improved product quality, reduced defects, and enhanced overall system performance, resulting in increased customer satisfaction.

How Eurolabs Validation Services Can Help

At Eurolab, our team of experts provides comprehensive validation services for robotic joint torque in high-speed manufacturing systems. Our laboratory is equipped with state-of-the-art equipment and follows industry-recognized standards to ensure accurate and reliable results. By choosing Eurolab, businesses can benefit from

Expertise Our team has extensive experience in validating robotic joints and understands the complexities of high-speed manufacturing systems.

Accurate Results We use advanced equipment and follow industry-recognized standards to ensure accurate and reliable torque measurements.

Comprehensive Reporting We provide detailed reports, including torque data, recommendations for improvement, and suggestions for optimizing system performance.

Frequently Asked Questions

Q What is the purpose of validation of robotic joint torque?

A Validation of robotic joint torque ensures that individual joints operate within specified tolerances, preventing errors, reducing wear and tear, and optimizing system performance.

Q How do I know if my robot requires validation of robotic joint torque?

A If your robot is used in high-speed applications or has experienced issues with accuracy, efficiency, or reliability, it may benefit from validation of robotic joint torque.

Q What are the benefits of validating robotic joint torque in high-speed manufacturing systems?

A Validation of robotic joint torque offers numerous benefits, including improved product quality, increased efficiency, enhanced reliability, and compliance with industry standards.

Q How long does the validation process take?

A The duration of the validation process depends on various factors, including system complexity and the number of joints to be tested. Our team will work closely with you to determine the best approach and provide a customized timeline.

Conclusion

In todays fast-paced manufacturing landscape, businesses cannot afford to compromise on quality or efficiency. Validation of robotic joint torque in high-speed manufacturing systems is an essential laboratory service provided by Eurolab that ensures precision, accuracy, and reliability. By choosing our comprehensive validation services, companies can improve product quality, increase efficiency, enhance reliability, and comply with industry standards.