Validation of joint torque in robots performing precision tasks

The Importance of Validation of Joint Torque in Robots Performing Precision Tasks Why Businesses Cant Afford to Ignore It

In todays fast-paced and highly competitive industrial landscape, precision tasks are more critical than ever before. From manufacturing high-quality electronics to performing intricate medical procedures, robots have become an integral part of many industries. However, as robotics technology continues to advance, the need for precise control and accuracy has also increased. This is where Validation of joint torque in robots performing precision tasks comes into play.

At Eurolab, our laboratory service specializes in providing a comprehensive validation of joint torque in robots performing precision tasks. Our team of experts understands the intricacies involved in ensuring that your robotic system meets the required standards for precision and accuracy. In this article, we will delve into the importance of Validation of joint torque in robots performing precision tasks, highlighting its advantages, key benefits, and frequently asked questions.

What is Validation of Joint Torque in Robots Performing Precision Tasks?

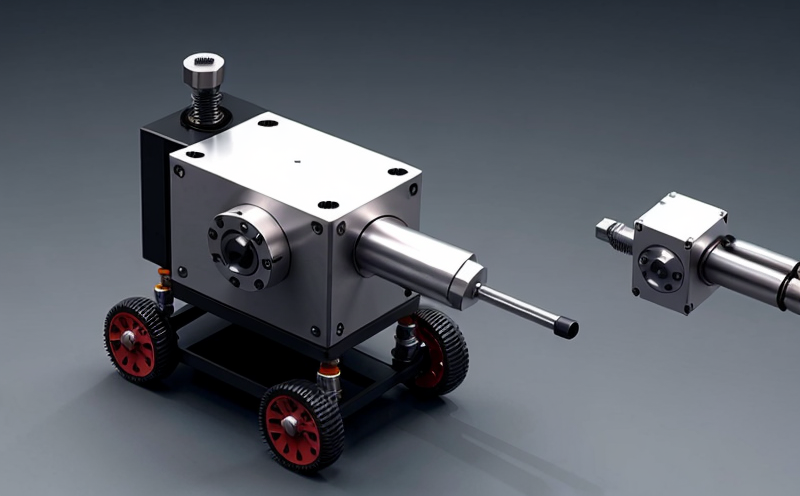

Validation of joint torque in robots performing precision tasks involves testing and verifying the robotic systems ability to generate precise and consistent joint torque. This process ensures that the robot can perform its intended tasks with accuracy and reliability. In simple terms, it verifies whether the robot can apply the correct amount of force at each joint to complete a specific task.

Why is Validation of Joint Torque in Robots Performing Precision Tasks Essential for Businesses?

In todays highly competitive market, businesses cant afford to compromise on precision and accuracy. Here are some compelling reasons why Validation of joint torque in robots performing precision tasks is essential

Advantages of Using Validation of Joint Torque in Robots Performing Precision Tasks

Improved Accuracy Validation ensures that the robotic system meets the required standards for precision and accuracy, reducing errors and improving overall performance.

Enhanced Reliability By verifying the joint torque, businesses can ensure that their robotic systems are reliable and less prone to breakdowns or failures.

Increased Productivity With precise control and accurate movements, robots can perform tasks faster and more efficiently, leading to increased productivity and reduced production costs.

Reduced Errors and Defects By minimizing errors and defects, businesses can improve product quality, enhance customer satisfaction, and reduce waste.

Key Benefits of Validation of Joint Torque in Robots Performing Precision Tasks

Here are the key benefits of using our laboratory service

Key Benefits for Manufacturers

Improved Quality Our validation process ensures that your robotic system meets the required standards for precision and accuracy.

Reduced Waste By minimizing errors and defects, manufacturers can reduce waste and improve product quality.

Increased Productivity With precise control and accurate movements, robots can perform tasks faster and more efficiently.

Key Benefits for Medical Institutions

Improved Patient Outcomes Our validation process ensures that robotic systems in medical institutions meet the required standards for precision and accuracy, leading to improved patient outcomes.

Reduced Complications By minimizing errors and defects, medical institutions can reduce complications and improve overall patient care.

Increased Efficiency With precise control and accurate movements, robots can perform tasks faster and more efficiently.

QA Section

Here are some frequently asked questions about Validation of joint torque in robots performing precision tasks

What is the purpose of validation of joint torque in robots performing precision tasks?

Validation of joint torque in robots performing precision tasks ensures that the robotic system meets the required standards for precision and accuracy, reducing errors and improving overall performance.

How does Eurolabs laboratory service ensure the accuracy of our robotic systems?

Our team of experts uses state-of-the-art equipment and rigorous testing protocols to verify the joint torque and ensure that your robotic system meets the required standards for precision and accuracy.

Can I trust Eurolab with my sensitive data and intellectual property?

Absolutely. At Eurolab, we understand the importance of confidentiality and security. We have implemented robust measures to protect your data and intellectual property.

Conclusion

In conclusion, Validation of joint torque in robots performing precision tasks is a critical process that ensures the accuracy and reliability of robotic systems. By using our laboratory service at Eurolab, businesses can improve their product quality, increase productivity, and reduce errors and defects. Dont compromise on precision and accuracy; choose Eurolab for your validation needs.

If youre interested in learning more about how Eurolab can help you with Validation of joint torque in robots performing precision tasks, please visit our website to learn more about our services and capabilities.