The Power of Shear Testing Unlocking Material Strength for Business Success

As businesses continue to push the boundaries of innovation and excellence, the importance of accurately assessing material strength cannot be overstated. This is where Shear Testing comes in a laboratory service provided by Eurolab that empowers companies to make informed decisions about their products and materials.

What is Shear Testing?

Shear Testing is a scientific process that measures the ability of a material to resist shear stress, which occurs when a force is applied parallel or tangential to the surface of the material. This type of testing is essential for businesses involved in various industries, including construction, manufacturing, and materials science. By determining the shear strength of a material, companies can ensure their products are safe, durable, and meet regulatory requirements.

The Advantages of Shear Testing

Eurolabs Shear Testing service offers numerous benefits to businesses, which can be summarized as follows

Improved Product Reliability

Reduced risk of product failure

Increased customer satisfaction through improved performance

Enhanced reputation through consistent quality

Enhanced Material Selection

Accurate identification of suitable materials for specific applications

Better understanding of material properties and limitations

Optimized material usage, reducing waste and costs

Compliance with Regulations

Adherence to industry standards and regulations

Reduced risk of non-compliance and associated penalties

Enhanced reputation through adherence to best practices

Informed Decision Making

Data-driven decisions based on accurate material properties

Increased confidence in product development and testing

Improved collaboration between stakeholders and team members

Cost Savings

Reduced material waste and re-work due to inaccurate testing

Optimized production processes, reducing labor costs and lead times

Improved supply chain management through informed material selection

How Shear Testing Works

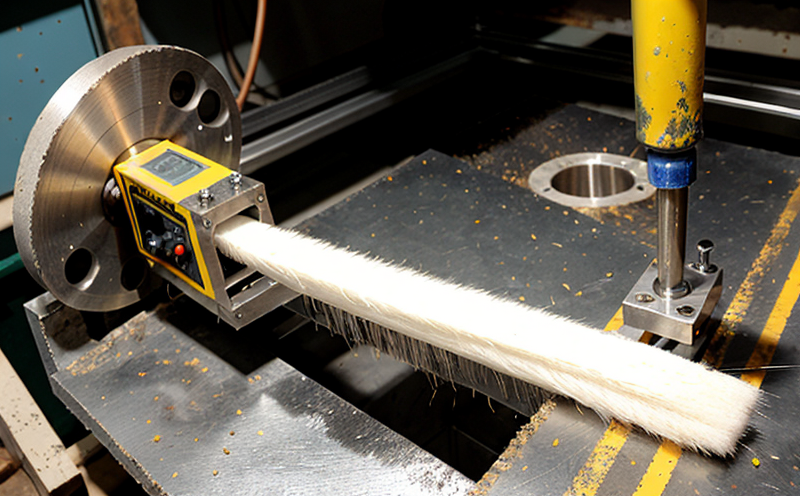

At Eurolab, our expert technicians use state-of-the-art equipment to conduct Shear Testing in accordance with industry-standard protocols. The process involves

Sample Preparation Material samples are carefully prepared for testing, ensuring accurate and reliable results.

Test Setup The sample is placed in a specialized fixture within the testing machine, which applies controlled shear forces.

Data Collection The machine collects data on the materials response to shear stress, including maximum load, deformation, and failure mode.

Results Analysis Our experienced analysts interpret the test results, providing clients with comprehensive reports and recommendations.

Frequently Asked Questions (FAQs)

What types of materials can be tested using Shear Testing?

Shear Testing is suitable for a wide range of materials, including metals, plastics, composites, ceramics, and more.

How long does the testing process take?

The duration of the test depends on the type of material and the specific testing protocol used. Typically, results are available within 24-48 hours.

What is the difference between Shear Testing and other types of mechanical testing?

Shear Testing measures a materials resistance to shear stress, which is distinct from tensile or compressive strength. Understanding the unique properties of materials is essential for informed decision making.

Can Eurolab provide custom testing protocols for specific applications?

Yes, our expert technicians work closely with clients to develop tailored testing protocols that meet their unique requirements.

Are Shear Testing results comparable across different laboratories?

Eurolab follows industry-standard protocols and maintains strict quality control measures to ensure accurate and reliable results.

Conclusion

In todays fast-paced business environment, companies must be able to rely on precise information about material strength. Eurolabs Shear Testing service provides the confidence businesses need to make informed decisions, optimize product development, and stay ahead of competitors. By investing in Shear Testing, companies can

Reduce risk and improve reliability

Enhance compliance with regulations

Drive cost savings through optimized production processes

Dont let material uncertainty hold you back choose Eurolabs Shear Testing service for unparalleled accuracy and expertise.

-

Testing the resistance of materials to forces that cause sliding or shearing failure

-

Simulating conditions where materials are subjected to lateral forces that could cause them to shear

-

Evaluating the shear strength of adhesives, coatings, and fasteners used in construction

-

Testing for material failure along internal planes or bonding points under shearing stresses

-

Verifying that building materials remain stable under conditions of lateral or horizontal movement

-

Ensuring that materials used in joints and connections resist shear forces during building operation

-

Simulating earthquake or wind forces to assess material performance under dynamic shear loading

-

Ensuring that structural connections, including bolts and welds, maintain their integrity under shear forces

-

Testing how materials perform when subjected to forces that cause one layer or part to slide over another

-

Ensuring that the shear strength of structural elements like beams and columns meets safety requirements

-

Testing for shear failure in building materials like wood, concrete, or steel to ensure durability

-

Simulating dynamic loading scenarios to test the shear performance of construction materials over time

-

Ensuring that shear forces do not compromise the overall stability of construction components

-

Verifying that materials used for exterior cladding or partitions maintain their shear strength under pressure

-

Testing the effect of shear forces on materials used in foundations and load-bearing walls

-

Evaluating shear strength in composite materials and their ability to resist splitting or separation

-

Testing the shear strength of different adhesives used in construction to ensure reliable bonding

-

Simulating shear forces caused by external factors such as wind, seismic activity, or traffic loads

-

Testing the shear capacity of materials used in roadways, bridges, and transportation infrastructure

-

Ensuring that shear failure does not lead to catastrophic structural damage in high-rise buildings

-

Verifying the shear resistance of materials used for roofing and walling to prevent buckling under stress

-

Ensuring that materials used in earthquake-prone areas can withstand shear forces without breaking or shifting