Testing for material failure along internal planes or bonding points under shearing stresses

Unlocking Reliability The Critical Importance of Testing for Material Failure Along Internal Planes or Bonding Points Under Shearing Stresses

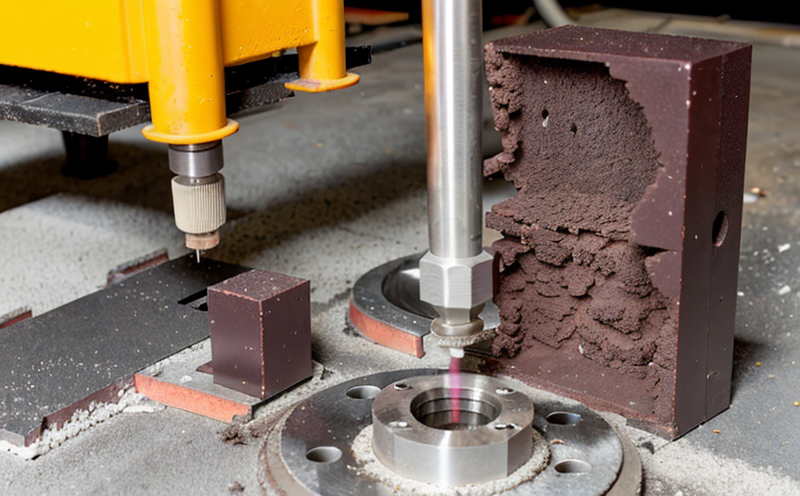

In the fast-paced world of manufacturing and engineering, ensuring the reliability and integrity of materials is paramount. One critical aspect of this endeavor is testing for material failure along internal planes or bonding points under shearing stresses a laboratory service that has become an indispensable tool for businesses seeking to mitigate risks and optimize performance.

At Eurolab, our team of expert engineers and technicians understands the significance of this testing methodology in identifying potential weaknesses within materials before they compromise product safety and efficacy. By harnessing cutting-edge technology and rigorous scientific protocols, we provide comprehensive testing solutions that empower companies to make informed decisions about their products and processes.

Why Testing for Material Failure Along Internal Planes or Bonding Points Under Shearing Stresses Matters

In todays competitive landscape, businesses are under immense pressure to deliver high-quality products while minimizing costs. However, the pursuit of efficiency can sometimes lead to compromises in material selection and processing potentially resulting in catastrophic failures that damage reputations and bottom lines.

Testing for material failure along internal planes or bonding points under shearing stresses addresses this concern by

Identifying hidden vulnerabilities Traditional testing methods often focus on surface-level evaluations, neglecting internal weaknesses that can lead to unexpected failures. Our comprehensive testing services ensure that all aspects of a materials integrity are scrutinized.

Enhancing product safety By understanding the potential failure modes of materials, businesses can implement targeted design and manufacturing improvements significantly reducing the risk of product-related accidents and injuries.

Optimizing resource allocation By identifying areas where costs can be trimmed without compromising performance, companies can redirect resources towards more innovative and value-driven initiatives.

The Advantages of Testing for Material Failure Along Internal Planes or Bonding Points Under Shearing Stresses

Our testing services offer numerous benefits to businesses seeking to excel in their respective industries

Improved product reliability By proactively identifying potential failure modes, companies can develop products that consistently meet or exceed performance expectations.

Enhanced brand reputation Demonstrating a commitment to quality and safety through rigorous testing helps build trust with customers and stakeholders driving loyalty and growth.

Increased efficiency By pinpointing areas where costs can be optimized without compromising performance, businesses can streamline operations and focus on innovation.

Key Benefits of Testing for Material Failure Along Internal Planes or Bonding Points Under Shearing Stresses

Some of the most significant advantages of our testing services include

Data-driven decision-making Our comprehensive reports provide actionable insights that inform product development and manufacturing strategies.

Cost savings through targeted improvements By identifying areas where costs can be trimmed without compromising performance, companies can redirect resources towards more innovative initiatives.

Enhanced regulatory compliance Demonstrating a commitment to quality and safety helps businesses navigate complex regulations with confidence.

Frequently Asked Questions About Testing for Material Failure Along Internal Planes or Bonding Points Under Shearing Stresses

At Eurolab, we understand that our testing services may raise questions about the process and its benefits. Below are some common queries, along with detailed answers

Q What types of materials can be tested using this method?

A Our testing services can accommodate a wide range of materials, including metals, polymers, ceramics, and composites.

Q How do you ensure the accuracy and reliability of your test results?

A We employ rigorous scientific protocols and state-of-the-art equipment to guarantee that our results are both accurate and reliable.

Q Can I request custom testing services tailored to my specific needs?

A Yes, we offer bespoke testing solutions designed in consultation with our clients to meet the unique requirements of their products or processes.

Conclusion

In conclusion, testing for material failure along internal planes or bonding points under shearing stresses is a critical component of any comprehensive quality control strategy. By harnessing the power of this methodology, businesses can unlock reliability and mitigate risks driving growth, innovation, and success.

At Eurolab, we are committed to empowering companies with the knowledge and tools necessary to excel in their respective industries. Join us in embracing the future of testing and development today.

-

Testing the resistance of materials to forces that cause sliding or shearing failure

-

Simulating conditions where materials are subjected to lateral forces that could cause them to shear

-

Evaluating the shear strength of adhesives, coatings, and fasteners used in construction

-

Verifying that building materials remain stable under conditions of lateral or horizontal movement

-

Ensuring that materials used in joints and connections resist shear forces during building operation

-

Simulating earthquake or wind forces to assess material performance under dynamic shear loading

-

Ensuring that structural connections, including bolts and welds, maintain their integrity under shear forces

-

Testing how materials perform when subjected to forces that cause one layer or part to slide over another

-

Ensuring that the shear strength of structural elements like beams and columns meets safety requirements

-

Testing for shear failure in building materials like wood, concrete, or steel to ensure durability

-

Simulating dynamic loading scenarios to test the shear performance of construction materials over time

-

Ensuring that shear forces do not compromise the overall stability of construction components

-

Verifying that materials used for exterior cladding or partitions maintain their shear strength under pressure

-

Testing the effect of shear forces on materials used in foundations and load-bearing walls

-

Evaluating shear strength in composite materials and their ability to resist splitting or separation

-

Testing the shear strength of different adhesives used in construction to ensure reliable bonding

-

Simulating shear forces caused by external factors such as wind, seismic activity, or traffic loads

-

Testing the shear capacity of materials used in roadways, bridges, and transportation infrastructure

-

Ensuring that shear failure does not lead to catastrophic structural damage in high-rise buildings

-

Verifying the shear resistance of materials used for roofing and walling to prevent buckling under stress

-

Ensuring that materials used in earthquake-prone areas can withstand shear forces without breaking or shifting