Simulating earthquake or wind forces to assess material performance under dynamic shear loading

Simulating Earthquake or Wind Forces to Assess Material Performance Under Dynamic Shear Loading A Critical Laboratory Service for Businesses

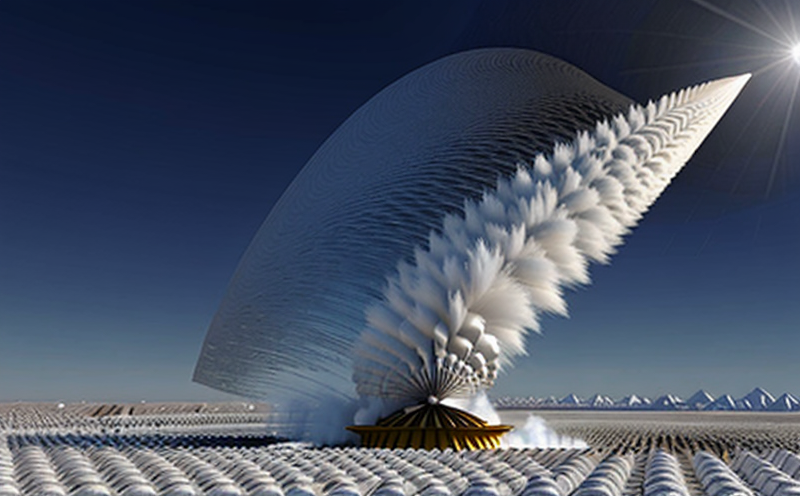

In todays fast-paced and increasingly demanding industrial landscape, businesses are constantly seeking innovative ways to ensure the reliability and performance of their products and materials. One critical aspect that often takes a backseat is the evaluation of material behavior under dynamic shear loading conditions. Earthquakes, hurricanes, and other extreme weather events can cause widespread damage and pose significant safety risks if not properly anticipated and mitigated.

This is where Eurolabs laboratory service comes in Simulating earthquake or wind forces to assess material performance under dynamic shear loading. By subjecting materials to controlled and realistic dynamic loads, our experts can help businesses like yours ensure the safety and integrity of their products, ultimately saving lives, reducing costs, and protecting reputations.

The Importance of Dynamic Shear Loading

Dynamic shear loading refers to the stress that occurs when a material is subjected to rapid changes in velocity or acceleration. This type of loading can be particularly damaging to materials, leading to cracking, deformation, or even catastrophic failure. Earthquakes and strong winds are prime examples of dynamic load events that can have devastating consequences.

Benefits of Simulating Earthquake or Wind Forces

By simulating earthquake or wind forces, Eurolabs laboratory service provides businesses with numerous benefits, including

Enhanced Product Safety Our tests help identify potential weaknesses in materials, ensuring they meet or exceed regulatory standards and industry benchmarks.

Reduced Risk of Catastrophic Failure By understanding how materials behave under dynamic load conditions, businesses can mitigate the risk of product failure, which can lead to costly downtime, damage to equipment, and even loss of life.

Increased Efficiency Our simulations enable companies to accelerate material development and testing cycles, reducing time-to-market for new products and minimizing delays caused by unforeseen problems.

Cost Savings By identifying potential issues early on, businesses can avoid expensive re-designs, recalls, or repairs, saving millions of dollars in the long run.

Compliance with Regulations Our laboratory service helps companies meet regulatory requirements, ensuring compliance with industry standards and reducing the risk of costly non-compliance fines.

Key Benefits of Eurolabs Laboratory Service

Some of the key benefits of our Simulating earthquake or wind forces to assess material performance under dynamic shear loading laboratory service include

Accurate and Reliable Results Our state-of-the-art equipment and expert team provide precise and trustworthy data, enabling businesses to make informed decisions about their products.

Customizable Testing Programs We work closely with clients to develop tailored testing programs that meet specific project requirements and industry standards.

Rapid Turnaround Times Our efficient testing process ensures quick turnaround times, allowing businesses to accelerate product development and get to market faster.

Expert Interpretation of Results Our team provides comprehensive analysis and interpretation of test results, helping businesses understand the implications for their products.

Frequently Asked Questions

Q What types of materials can be tested using Eurolabs Simulating earthquake or wind forces laboratory service?

A Our services are suitable for a wide range of materials, including metals, polymers, composites, and ceramics. We also offer testing for various product categories, such as building components, infrastructure systems, and consumer products.

Q How does the testing process work?

A The testing process typically begins with a consultation to discuss project requirements and develop a customized testing program. Our team will then conduct the tests using our state-of-the-art equipment and provide detailed analysis of the results.

Q Are the test results confidential?

A Yes, all test results are treated as confidential and shared only with authorized personnel.

Q Can Eurolabs laboratory service help me meet industry standards for material performance under dynamic load conditions?

A Absolutely. Our team has extensive experience working with regulatory bodies and industry associations to ensure compliance with relevant standards and guidelines.

Conclusion

In todays fast-paced business environment, companies cannot afford to compromise on product safety and reliability. By simulating earthquake or wind forces to assess material performance under dynamic shear loading, Eurolab provides businesses with a critical laboratory service that can make all the difference between success and failure. With our expertise, cutting-edge equipment, and commitment to delivering accurate and reliable results, we empower companies to ensure their products meet the highest standards of safety, efficiency, and performance.

Dont wait until its too late trust Eurolab to help you safeguard your business and protect the lives of those who depend on your products. Contact us today to learn more about our Simulating earthquake or wind forces laboratory service and discover how we can support your product development needs.

-

Testing the resistance of materials to forces that cause sliding or shearing failure

-

Simulating conditions where materials are subjected to lateral forces that could cause them to shear

-

Evaluating the shear strength of adhesives, coatings, and fasteners used in construction

-

Testing for material failure along internal planes or bonding points under shearing stresses

-

Verifying that building materials remain stable under conditions of lateral or horizontal movement

-

Ensuring that materials used in joints and connections resist shear forces during building operation

-

Ensuring that structural connections, including bolts and welds, maintain their integrity under shear forces

-

Testing how materials perform when subjected to forces that cause one layer or part to slide over another

-

Ensuring that the shear strength of structural elements like beams and columns meets safety requirements

-

Testing for shear failure in building materials like wood, concrete, or steel to ensure durability

-

Simulating dynamic loading scenarios to test the shear performance of construction materials over time

-

Ensuring that shear forces do not compromise the overall stability of construction components

-

Verifying that materials used for exterior cladding or partitions maintain their shear strength under pressure

-

Testing the effect of shear forces on materials used in foundations and load-bearing walls

-

Evaluating shear strength in composite materials and their ability to resist splitting or separation

-

Testing the shear strength of different adhesives used in construction to ensure reliable bonding

-

Simulating shear forces caused by external factors such as wind, seismic activity, or traffic loads

-

Testing the shear capacity of materials used in roadways, bridges, and transportation infrastructure

-

Ensuring that shear failure does not lead to catastrophic structural damage in high-rise buildings

-

Verifying the shear resistance of materials used for roofing and walling to prevent buckling under stress

-

Ensuring that materials used in earthquake-prone areas can withstand shear forces without breaking or shifting