Simulating electromagnetic interference in multi-joint robotic systems

Simulating Electromagnetic Interference in Multi-Joint Robotic Systems A Crucial Service for Businesses

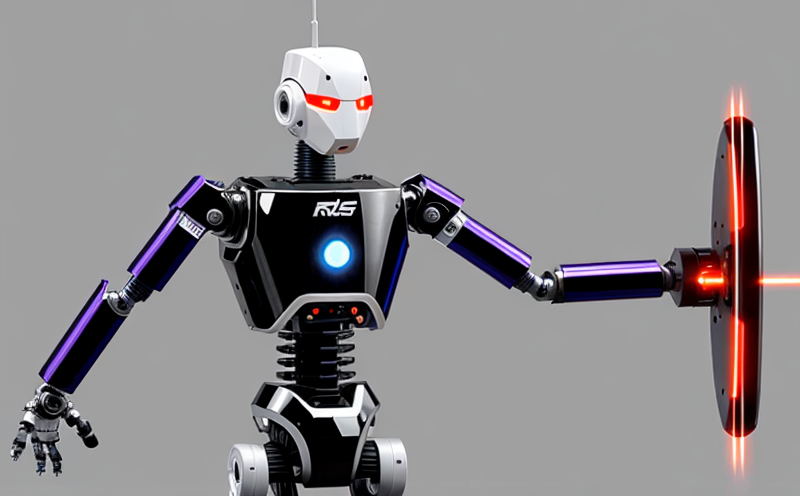

In todays rapidly evolving world of robotics and automation, manufacturers are constantly seeking innovative solutions to optimize their production processes. One critical aspect that often gets overlooked is the potential impact of electromagnetic interference (EMI) on multi-joint robotic systems. Electromagnetic interference can cause malfunctions, damage equipment, and compromise data integrity all of which can lead to costly downtime, reduced productivity, and compromised product quality.

At Eurolab, we understand the importance of ensuring the reliability and performance of your robotic systems. Our team offers a comprehensive laboratory service designed specifically for simulating electromagnetic interference in multi-joint robotic systems. This critical service enables manufacturers to identify potential EMI issues before they occur, thereby preventing costly problems down the line.

What is Electromagnetic Interference?

Electromagnetic interference occurs when an external electromagnetic field affects the operation of a device or system. In the context of robotics, EMI can be particularly problematic due to the presence of multiple moving parts, electrical components, and communication systems. When these components interact with their surroundings, they generate electromagnetic fields that can interfere with each other, causing malfunctions, data corruption, or even equipment damage.

Why is Simulating Electromagnetic Interference Essential?

Simulating EMI in multi-joint robotic systems offers a range of benefits that are essential for businesses looking to optimize their production processes. Some of the key advantages include

Early Detection and Prevention By simulating EMI, manufacturers can identify potential issues before they occur, preventing costly downtime and maintenance.

Improved Product Quality Reduced EMI enables more precise control over robotic movements, leading to higher-quality products and reduced waste.

Increased Efficiency With a better understanding of EMIs impact on their systems, manufacturers can optimize performance, reducing energy consumption and minimizing equipment wear.

Reduced Costs By identifying and mitigating EMI issues early on, businesses can avoid costly repairs, replacements, and production delays.

Key Benefits of Simulating Electromagnetic Interference in Multi-Joint Robotic Systems

Compliance with Industry Standards Our laboratory service ensures that your robotic systems meet or exceed regulatory requirements for electromagnetic compatibility (EMC).

Customized Solutions We provide tailored EMI simulations to address specific system configurations and environmental conditions.

Data-Driven Decision Making Our comprehensive reports offer actionable insights, enabling you to make informed decisions about equipment maintenance, upgrades, and operational procedures.

Enhanced Product Development By understanding the impact of EMI on your systems, you can design and develop more efficient, reliable, and high-performance robotic solutions.

How Does Eurolabs Laboratory Service Work?

Our team at Eurolab employs cutting-edge technology and expert knowledge to simulate electromagnetic interference in multi-joint robotic systems. The process involves

System Analysis We thoroughly evaluate your robotic systems configuration, operational parameters, and environmental conditions.

Simulation Design Our experts design a customized simulation plan tailored to your specific needs and requirements.

Testing and Evaluation We conduct rigorous EMI simulations using state-of-the-art equipment and data analysis tools.

Reporting and Recommendations We provide comprehensive reports detailing the results of our testing, along with actionable recommendations for mitigating EMI issues.

Frequently Asked Questions (FAQs)

Q What types of robotic systems can you simulate electromagnetic interference on?

A Our laboratory service is designed to accommodate a wide range of multi-joint robotic systems, including but not limited to robotic arms, grippers, and assembly machines.

Q How long does the simulation process typically take?

A The duration of our simulation services varies depending on the complexity of your system and the level of customization required. Our team will work closely with you to ensure that your needs are met efficiently and effectively.

Q What kind of data can I expect from the testing results?

A We provide comprehensive reports detailing the EMI impacts on your systems, including frequency spectra, signal strength, and potential interference sources.

Q Can I request additional services or support beyond the standard simulation package?

A Absolutely. Our team is committed to providing exceptional service and supports customized packages tailored to meet your specific needs.

Conclusion

In todays fast-paced world of robotics and automation, simulating electromagnetic interference in multi-joint robotic systems is a critical step towards ensuring the reliability, efficiency, and performance of your production processes. At Eurolab, we are dedicated to providing cutting-edge laboratory services that help manufacturers identify and mitigate potential EMI issues before they become costly problems.

By partnering with us, youll gain access to expert knowledge, state-of-the-art technology, and actionable insights that drive business success. Whether youre looking to optimize production efficiency, improve product quality, or reduce costs, our laboratory service is designed to meet your unique needs.

Get in touch with Eurolab today to discover how simulating electromagnetic interference can transform the performance of your multi-joint robotic systems.