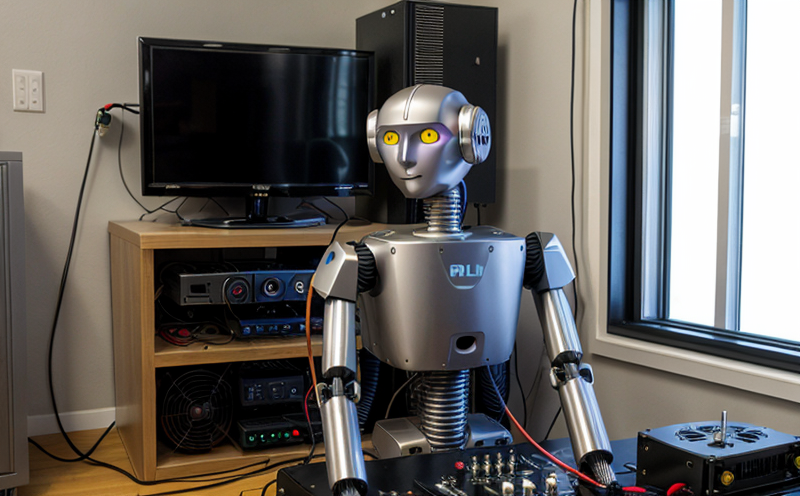

Testing electromagnetic interference (EMI) in robotic systems

Unlocking Safe and Reliable Robotic Operations The Importance of Testing Electromagnetic Interference (EMI) in Robotic Systems

In todays rapidly advancing industrial landscape, robotic systems have become an indispensable part of numerous industries, including manufacturing, logistics, healthcare, and more. These sophisticated machines are designed to streamline processes, enhance productivity, and improve product quality. However, as the complexity of these systems increases, so do the risks associated with their operation. One critical aspect that often goes unnoticed is the potential for electromagnetic interference (EMI) in robotic systems.

What is Electromagnetic Interference (EMI)?

Electromagnetic interference occurs when an external electromagnetic field disrupts the normal functioning of electronic equipment or systems. In the context of robotic systems, EMI can be particularly problematic, as it may cause malfunctioning, data corruption, or even complete system failure. This can lead to costly downtime, lost productivity, and compromised product quality.

Why is Testing Electromagnetic Interference (EMI) in Robotic Systems Essential?

Testing electromagnetic interference (EMI) in robotic systems is no longer a nicety; its a necessity for businesses looking to ensure safe and reliable operations. The benefits of EMI testing are numerous, and they can have a direct impact on your bottom line.

Advantages of Using Testing Electromagnetic Interference (EMI) in Robotic Systems

Improved System Reliability By identifying potential sources of EMI, you can take proactive measures to mitigate the risks associated with electromagnetic interference. This ensures that your robotic systems operate as intended, minimizing downtime and reducing maintenance costs.

Enhanced Product Quality Electromagnetic interference can lead to data corruption or equipment malfunctioning, which may compromise product quality. Regular EMI testing helps ensure that your products meet the required standards, reducing the likelihood of costly recalls or rework.

Compliance with Regulations Many industries have regulations governing electromagnetic compatibility (EMC). By performing regular EMI testing, you can demonstrate compliance with these regulations, avoiding potential fines and reputational damage.

Cost Savings Identifying and addressing EMI issues before they become major problems can help reduce maintenance costs and minimize the risk of costly equipment failures.

Increased Efficiency Robotic systems that are free from EMI issues operate more efficiently, allowing for increased productivity and improved output.

How Does Eurolab Help?

At Eurolab, we understand the importance of testing electromagnetic interference (EMI) in robotic systems. Our expert team has developed a comprehensive laboratory service designed to identify potential sources of EMI and ensure that your systems meet the required standards.

Our state-of-the-art facilities are equipped with advanced equipment and tools, enabling us to perform thorough and accurate EMI testing. Our experienced engineers work closely with clients to understand their specific needs and provide tailored solutions.

What Sets Us Apart?

At Eurolab, we pride ourselves on our commitment to delivering exceptional service, quality results, and timely delivery. Here are just a few reasons why you should choose us for your EMI testing needs

Expertise Our team has extensive experience in testing electromagnetic interference (EMI) in robotic systems, ensuring that you receive accurate and reliable results.

State-of-the-Art Facilities Our laboratories are equipped with the latest equipment and tools, enabling us to perform thorough and accurate EMI testing.

Personalized Service We take the time to understand your specific needs and provide tailored solutions to meet your requirements.

QA Frequently Asked Questions

Q What is the purpose of testing electromagnetic interference (EMI) in robotic systems?

A The primary goal of EMI testing is to identify potential sources of electromagnetic interference that may disrupt the normal functioning of electronic equipment or systems. This ensures safe and reliable operations, minimizing downtime and reducing maintenance costs.

Q How often should I perform EMI testing on my robotic systems?

A The frequency of EMI testing depends on various factors, including system complexity, operating environment, and regulatory requirements. Its essential to consult with our experts to determine the best testing schedule for your specific needs.

Q Can I perform EMI testing in-house, or do I need to outsource to a laboratory?

A While some organizations may have the necessary expertise and equipment to perform EMI testing, its often more efficient and cost-effective to outsource this task to a specialized laboratory like Eurolab. Our team has extensive experience and access to advanced equipment, ensuring accurate and reliable results.

Q What are the benefits of using a laboratory service for EMI testing?

A By partnering with a laboratory service, you can ensure that your robotic systems meet the required standards, reducing the likelihood of costly equipment failures or downtime. Our experts will work closely with you to identify potential sources of EMI and provide tailored solutions.

Conclusion

Testing electromagnetic interference (EMI) in robotic systems is no longer an optional extra; its a critical aspect of ensuring safe and reliable operations. At Eurolab, were committed to providing expert laboratory services that help businesses like yours minimize the risks associated with EMI.

Dont let electromagnetic interference compromise your product quality or compliance with regulations. Trust our team at Eurolab to identify potential sources of EMI and ensure that your robotic systems operate as intended.

Learn More About Our Laboratory Services

Contact us today to discover how our expert team can help you navigate the complex world of EMI testing. Together, we can unlock safe and reliable operations for your business.