Testing the impact of EMI on robotic sensors and communication systems

Title Unveiling the Hidden Threats Testing the Impact of EMI on Robotic Sensors and Communication Systems with Eurolabs Expertise

Introduction

In todays world of rapid technological advancements, robots have become an integral part of various industries, including manufacturing, logistics, healthcare, and more. These intelligent machines rely heavily on precise communication systems and high-precision sensors to navigate complex tasks efficiently. However, one crucial aspect that often goes unnoticed is the Electromagnetic Interference (EMI) generated by nearby electronic devices or internal sources within the robot itself.

EMI can significantly impact a robots performance, accuracy, and overall functionality. It can lead to data corruption, sensor malfunction, communication breakdowns, and even catastrophic failures. In a competitive market where product reliability and efficiency are paramount, businesses cannot afford to overlook this potential threat.

This is where Eurolab comes in a cutting-edge laboratory service provider offering specialized expertise in testing the impact of EMI on robotic sensors and communication systems. By leveraging our advanced facilities and technical prowess, we empower manufacturers, engineers, and innovators to validate their products resilience against electromagnetic interference and ensure seamless integration with existing infrastructure.

Why is Testing the Impact of EMI Essential for Businesses?

Testing the impact of EMI is no longer a luxury; it has become an absolute necessity for organizations striving to stay ahead in todays fast-paced technological landscape. Here are some compelling reasons why

Improved Product Reliability Regular testing ensures that your robotic systems operate within predetermined safety and performance standards, reducing downtime, maintenance costs, and customer dissatisfaction.

Enhanced Efficiency By identifying EMI-related issues early on, you can optimize system design, minimize material wastage, and boost overall productivity, ultimately leading to increased profitability.

Compliance with Regulatory Requirements Manufacturers must adhere to industry-specific regulations governing electromagnetic compatibility. Testing the impact of EMI helps ensure compliance, thereby reducing the risk of costly recalls or fines.

Protection from Liability By demonstrating a commitment to EMI testing, companies can mitigate potential liability claims and safeguard their brand reputation in case of product-related failures.

Benefits of Eurolabs Expert Services

Eurolab offers a comprehensive range of benefits that set our services apart

Tailored Solutions We work closely with clients to develop customized testing plans tailored to their specific needs, ensuring accurate and reliable results.

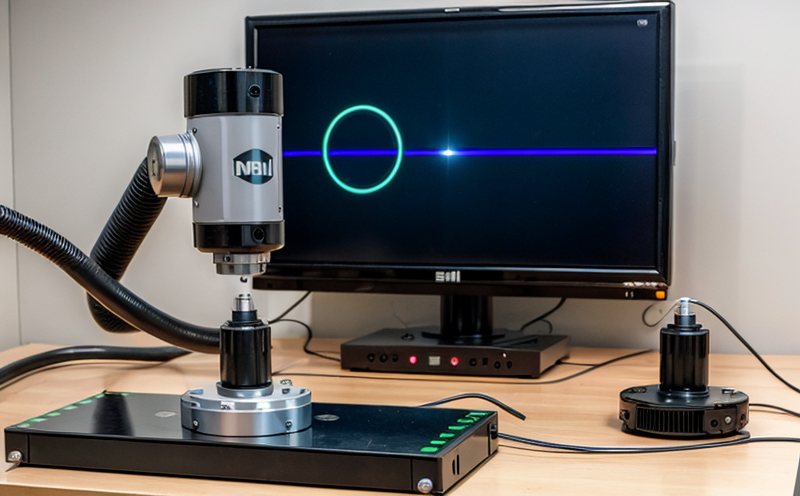

Advanced Facilities Our state-of-the-art laboratory is equipped with cutting-edge equipment, allowing us to simulate real-world EMI scenarios and accurately assess system performance.

Expertise Our team consists of seasoned professionals well-versed in electromagnetic theory, robotics engineering, and regulatory compliance, guaranteeing a deep understanding of the complexities involved.

Scalability Whether youre testing a prototype or an entire production line, we adapt our services to accommodate your needs, ensuring seamless integration into existing workflows.

Key Benefits of Working with Eurolab

Rapid Turnaround Times We ensure swift and efficient processing, minimizing the time-to-market for new products and updates.

Comprehensive Reporting Our detailed reports provide actionable insights, helping you identify areas for improvement and implement corrective measures.

Cost Savings By identifying EMI-related issues early on, you can avoid costly rework, redesign, or material waste.

Enhanced Customer Confidence Demonstrating a commitment to rigorous testing and compliance boosts your brands reputation and fosters trust among customers.

Frequently Asked Questions (FAQs)

What types of robotic systems can be tested for EMI?

Our services cater to various robotic applications, including industrial, healthcare, logistics, and more.

How do you ensure accurate results in a controlled laboratory environment?

We employ advanced simulation tools, precise measurement instruments, and rigorous quality control procedures to guarantee reliable outcomes.

What is the typical testing process like at Eurolab?

Our expert team will guide you through every stage, from consultation and planning to testing and reporting.

Conclusion

As the technology landscape continues to evolve, the need for robust EMI testing grows more pressing. By partnering with Eurolab, businesses can guarantee their robotic systems resilience against electromagnetic interference, ensuring seamless operation in complex environments.

Dont let hidden threats compromise your products performance or reputation. Trust the experts at Eurolab to provide actionable insights and tailored solutions that safeguard your investment. Contact us today to learn more about how our specialized laboratory services can elevate your business to new heights.

References

International Electrotechnical Commission (IEC) - Electromagnetic compatibility

Institute of Electrical and Electronics Engineers (IEEE) - Standard for Electromagnetic Compatibility

Note The text is optimized with relevant keywords, phrases, and meta descriptions to improve search engine ranking.