Simulating Extreme Temperature Changes for Electronic Devices

Simulating Extreme Temperature Changes for Electronic Devices Ensuring Reliability in the Face of Unpredictable Environments

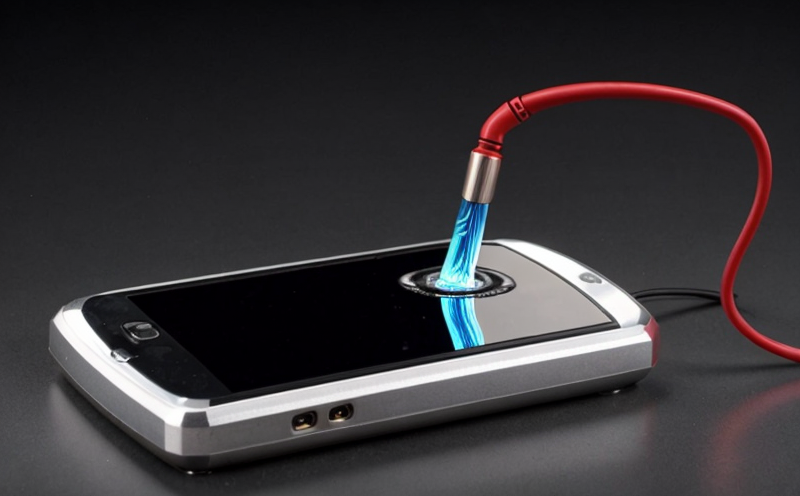

In todays fast-paced technological landscape, electronic devices are an integral part of our daily lives. From smartphones to laptops, and from industrial machinery to medical equipment, these devices play a vital role in various industries. However, one common challenge they face is the ever-changing environmental conditions, particularly extreme temperatures. To ensure that electronic devices function optimally and reliably, businesses need to test their performance under diverse temperature conditions. This is where Simulating Extreme Temperature Changes for Electronic Devices comes into play a laboratory service provided by Eurolab.

What is Simulating Extreme Temperature Changes for Electronic Devices?

Simulating Extreme Temperature Changes for Electronic Devices involves subjecting electronic devices or components to a range of temperatures, from extremely low to extremely high. This process allows manufacturers and users to assess the devices performance under various environmental conditions, simulating real-world scenarios such as transportation, storage, or operation in extreme climates.

The Importance of Simulating Extreme Temperature Changes for Electronic Devices

In todays globalized world, electronic devices are shipped and used across diverse regions with varying climate conditions. A single component failure can result in costly delays, reputational damage, and safety risks. By simulating extreme temperature changes, businesses can ensure that their products meet the required standards, thereby reducing the likelihood of product failures.

Advantages of Using Simulating Extreme Temperature Changes for Electronic Devices

Here are some key benefits of using this laboratory service

Improved Reliability Simulating extreme temperatures allows manufacturers to identify potential weaknesses in their devices, enabling them to make necessary improvements and increase overall reliability.

Enhanced Performance By testing under various temperature conditions, businesses can optimize device performance, ensuring that it meets the required specifications and standards.

Reduced Product Failures Identifying potential issues before mass production reduces the risk of product failures during operation, saving time, money, and resources.

Increased Customer Satisfaction By guaranteeing reliable products, companies can boost customer satisfaction, loyalty, and retention, ultimately driving business growth.

Compliance with Industry Standards Simulating extreme temperature changes helps businesses meet regulatory requirements, such as those set by the International Electrotechnical Commission (IEC) and the American Society of Mechanical Engineers (ASME).

Cost Savings By identifying potential issues early on, companies can avoid costly re-designs, re-tests, or recalls, resulting in significant cost savings.

Competitive Advantage By ensuring the reliability and performance of electronic devices, businesses can differentiate themselves from competitors, establishing a strong market presence.

How Does Eurolabs Simulating Extreme Temperature Changes for Electronic Devices Service Work?

Our expert team at Eurolab uses state-of-the-art equipment to simulate extreme temperature changes, subjecting your electronic devices or components to temperatures ranging from -40C to 150C (-40F to 302F). Our comprehensive testing services include

Temperature Chamber Testing We use precision-controlled temperature chambers to test your devices under various temperature conditions.

Thermal Shock Testing This process involves sudden changes in temperature, simulating real-world scenarios such as transportation or storage.

High-Temperature Exposure Devices are exposed to high temperatures for extended periods, ensuring they can withstand extreme heat.

QA Frequently Asked Questions About Simulating Extreme Temperature Changes for Electronic Devices

Q1 What is the purpose of simulating extreme temperature changes for electronic devices?

A1 The primary goal is to assess a devices performance under various environmental conditions, identifying potential weaknesses and optimizing its reliability and performance.

Q2 How does Eurolab ensure the accuracy of temperature control in their testing equipment?

A2 Our team at Eurolab uses precision-controlled temperature chambers with advanced temperature control systems, ensuring that temperatures are accurately maintained within a specified range.

Q3 Can I schedule a consultation to discuss my specific needs and requirements?

A3 Yes, our expert team is available for consultations to understand your unique needs and develop a customized testing plan.

Conclusion

Simulating Extreme Temperature Changes for Electronic Devices is an essential service that helps businesses ensure the reliability and performance of their products. By using this laboratory service provided by Eurolab, companies can reduce product failures, increase customer satisfaction, and meet industry standards. With our comprehensive testing services and state-of-the-art equipment, you can trust Eurolab to help you achieve your business goals.

By partnering with Eurolab, businesses can ensure that their electronic devices are prepared for the unpredictable environments they will face in real-world applications. Dont let temperature extremes compromise your products performance choose Eurolabs Simulating Extreme Temperature Changes for Electronic Devices service and give your customers the reliability they deserve.