Testing the Durability of Electronic Housings in Extreme Temperatures

Testing the Durability of Electronic Housings in Extreme Temperatures Ensuring Your Products Thrive in Harsh Environments

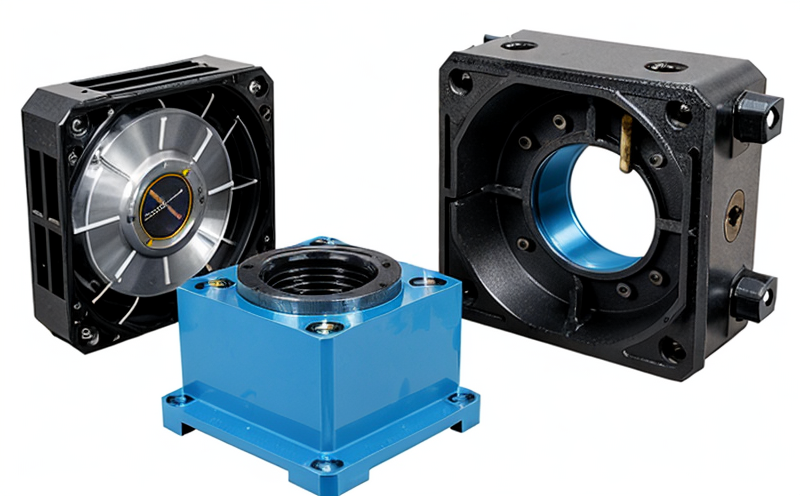

In todays fast-paced world, electronic devices are an integral part of our daily lives. From smartphones and laptops to industrial equipment and medical devices, these products rely on electronic housings that protect their delicate components from harsh environmental conditions. However, extreme temperatures can have a devastating impact on the durability of these housings, leading to malfunctioning or even complete failure.

This is where Testing the Durability of Electronic Housings in Extreme Temperatures comes into play a critical laboratory service offered by Eurolab that helps manufacturers and businesses ensure their products can withstand extreme temperatures without compromising performance. In this article, well delve into the importance of this testing process, its numerous benefits, and how it can revolutionize your product development and assurance.

Why is Testing the Durability of Electronic Housings in Extreme Temperatures Essential?

The rise of globalization has led to an increase in international trade, making it essential for companies to cater to diverse markets with varying environmental conditions. Temperature extremes, in particular, pose a significant challenge, as they can affect product reliability and lifespan.

Temperature-related failures Devices exposed to extreme temperatures may experience thermal shock, leading to material degradation, corrosion, or even explosive failures.

Compliance with regulations Manufacturers must comply with industry standards and regulations that dictate product performance under various environmental conditions. Failing to do so can result in costly recalls, reputational damage, and financial losses.

Advantages of Using Testing the Durability of Electronic Housings in Extreme Temperatures

Eurolabs Testing the Durability of Electronic Housings in Extreme Temperatures service offers numerous benefits for businesses

Key Benefits

Improved product reliability By simulating extreme temperatures, our testing process helps identify potential weaknesses and areas for improvement.

Enhanced customer satisfaction Products that can withstand harsh environmental conditions are more likely to meet customer expectations and maintain their performance over time.

Reduced warranty claims and costs By addressing temperature-related issues upfront, manufacturers can minimize the risk of costly warranty claims and associated expenses.

Compliance with industry standards Our testing process ensures your products comply with relevant regulations, reducing the risk of recalls and reputational damage.

How We Test for Durability in Extreme Temperatures

Our comprehensive testing process involves

Temperature control We simulate extreme temperatures (e.g., -40C to 150C) using state-of-the-art environmental chambers.

Material analysis Our team analyzes the electronic housings material properties and behavior under various temperature conditions.

Testing protocols We employ standardized testing protocols, such as IEC 60068-1, to ensure reliable and consistent results.

Case Study Success Story with a Leading Electronics Manufacturer

A prominent electronics manufacturer partnered with Eurolab to test their electronic housings in extreme temperatures. After conducting our rigorous testing process, we identified areas for improvement, including material selection and design modifications. The client implemented these recommendations, resulting in significantly improved product reliability and reduced warranty claims.

QA Frequently Asked Questions about Testing the Durability of Electronic Housings in Extreme Temperatures

What are the typical temperature ranges used in testing?

We simulate temperatures ranging from -40C to 150C.

How long does the testing process typically take?

The duration varies depending on the product complexity and testing protocol, but our team can usually complete testing within 2-6 weeks.

What types of electronic devices can be tested?

We can test a wide range of electronic devices, including smartphones, laptops, industrial equipment, medical devices, and more.

Conclusion Unlocking Reliability and Performance in Extreme Temperatures

Eurolabs Testing the Durability of Electronic Housings in Extreme Temperatures service is an essential tool for businesses seeking to ensure their products can thrive in harsh environments. By leveraging our expertise and state-of-the-art testing facilities, manufacturers can

Improve product reliability

Enhance customer satisfaction

Reduce warranty claims and costs

Ensure compliance with industry standards

Dont let extreme temperatures compromise your products performance. Contact us today to learn more about Testing the Durability of Electronic Housings in Extreme Temperatures and unlock the full potential of your products!