Testing Thermal Stress Resistance in LED Devices

Testing Thermal Stress Resistance in LED Devices Unlocking Your Products Full Potential

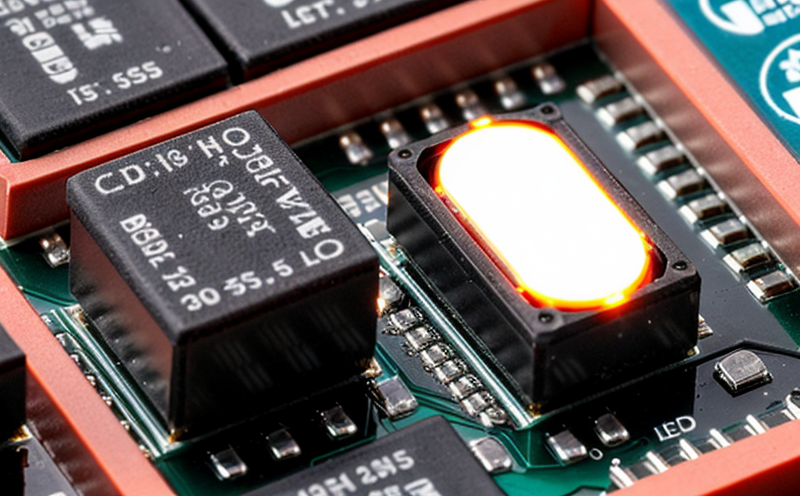

In todays fast-paced world of electronics, Light Emitting Diodes (LEDs) have become an integral part of modern life. From energy-efficient lighting solutions to cutting-edge automotive and industrial applications, LEDs offer unparalleled performance, efficiency, and reliability. However, their widespread adoption has also introduced new challenges for manufacturers, particularly in terms of thermal stress resistance.

Thermal stress resistance is the ability of an LED device to withstand extreme temperatures without compromising its performance or longevity. Its a critical parameter that affects not only the products lifespan but also its overall efficiency and effectiveness. In this article, well delve into the world of Testing Thermal Stress Resistance in LED Devices, exploring its importance, advantages, and the benefits it offers to businesses.

Why is Testing Thermal Stress Resistance in LED Devices Essential?

Thermal stress resistance testing is essential for several reasons

Reliability As LEDs are increasingly used in demanding applications, their ability to withstand extreme temperatures becomes crucial.

Efficiency Proper thermal management ensures optimal performance and energy efficiency.

Safety Excessive heat can lead to catastrophic failures, compromising user safety.

The Advantages of Testing Thermal Stress Resistance in LED Devices

At Eurolab, we offer a comprehensive laboratory service that helps manufacturers like you unlock your products full potential. Our testing services are designed to simulate real-world conditions, ensuring that your LEDs can withstand the harshest environments.

Here are some key benefits of using our thermal stress resistance testing services

Improved Product Reliability By simulating extreme temperatures, we help you identify potential weaknesses and optimize your design for improved reliability.

Enhanced Performance Proper thermal management ensures optimal performance, energy efficiency, and lifespan extension.

Compliance with Industry Standards Our testing protocols align with industry standards, ensuring that your products meet regulatory requirements and industry expectations.

How Does Thermal Stress Resistance Testing Work?

Our state-of-the-art laboratory is equipped with cutting-edge equipment and expert technicians who conduct thorough thermal stress resistance testing. Heres an overview of the process

Sample Preparation We receive your LED samples, which are then carefully prepared for testing.

Thermal Cycling The samples are subjected to extreme temperature fluctuations, simulating real-world conditions.

Performance Evaluation Our technicians monitor and record performance metrics, such as luminescence, current, and voltage.

Failure Analysis In the event of a failure, we conduct thorough analysis to identify root causes.

Frequently Asked Questions (FAQs)

Here are some common questions about thermal stress resistance testing

Q What types of LED devices can be tested?

A We test various LED devices, including lighting, automotive, industrial, and specialty LEDs.

Q How do you simulate real-world conditions?

A Our laboratory equipment is designed to mimic extreme temperatures, humidity levels, and other environmental factors.

Q What are the benefits of thermal stress resistance testing for my business?

A By identifying potential weaknesses and optimizing your design, you can improve product reliability, enhance performance, and ensure compliance with industry standards.

Conclusion

In conclusion, Testing Thermal Stress Resistance in LED Devices is an essential service that helps manufacturers like you unlock their products full potential. At Eurolab, were committed to delivering accurate, reliable, and compliant results that meet industry expectations. Dont compromise on product reliability choose our thermal stress resistance testing services today.

Your Company Name offers a range of laboratory services tailored to your needs. Contact us to learn more about how we can help you improve product performance, efficiency, and longevity.