Simulating mechanical stress and vibration to evaluate how adhesives perform in dynamic environments

The Unrivaled Power of Dynamic Adhesive Testing Simulating Mechanical Stress and Vibration to Ensure Unmatched Performance

In the ever-evolving landscape of industry and manufacturing, one factor stands above the rest in determining the success of a product adhesive performance. The ability of an adhesive to withstand dynamic environments is paramount, yet often overlooked until its too late. Thats where Eurolab comes in our comprehensive laboratory service dedicated to simulating mechanical stress and vibration to evaluate how adhesives perform in dynamic environments.

In this article, well delve into the intricacies of Simulating mechanical stress and vibration to evaluate how adhesives perform in dynamic environments, highlighting its importance, benefits, and advantages. Whether youre a seasoned manufacturer or an innovative start-up, understanding the value of dynamic adhesive testing can be the difference between a successful product launch and catastrophic failure.

What is Simulating Mechanical Stress and Vibration?

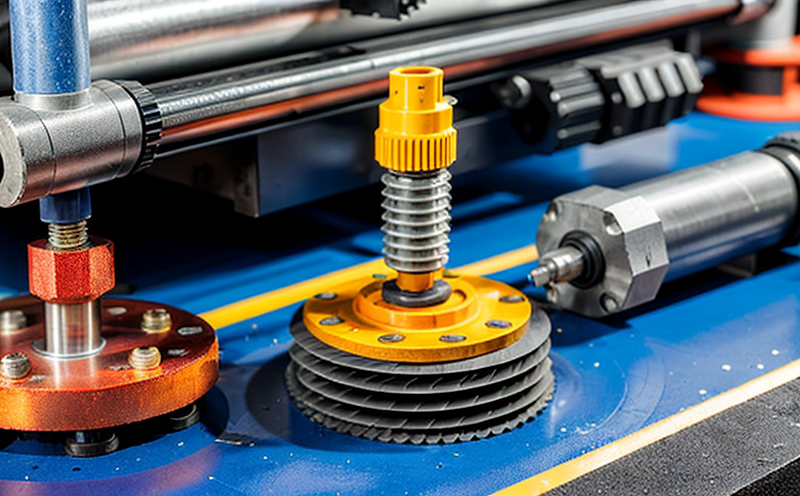

Simulating mechanical stress and vibration involves subjecting adhesives to various forms of dynamic forces, mimicking real-world conditions. This process allows manufacturers to assess an adhesives ability to withstand

Vibration Sudden, rapid movements that can cause bonding failure

Shock Abrupt impacts that put immense pressure on the bond

Torsion Twisting forces that can lead to delamination

By simulating these conditions in a controlled laboratory setting, Eurolabs experts can provide critical insights into an adhesives performance under stress.

Why is Simulating Mechanical Stress and Vibration Essential for Businesses?

In todays fast-paced industry, manufacturers face immense pressure to deliver high-quality products that meet the demands of dynamic environments. The consequences of failing to do so are dire product failure, customer dissatisfaction, and costly rework or even recalls.

By utilizing Eurolabs Simulating mechanical stress and vibration service, businesses can

Ensure Product Reliability Dynamically tested adhesives provide peace of mind, knowing that products will withstand the rigors of real-world conditions.

Reduce Costs Identifying potential issues before product launch saves time, money, and resources.

Enhance Brand Reputation Demonstrating commitment to quality through rigorous testing fosters customer trust and loyalty.

Key Benefits of Simulating Mechanical Stress and Vibration

Eurolabs laboratory service offers a comprehensive range of benefits, including

Improved Adhesive Selection Identify the most suitable adhesive for your specific application, ensuring optimal performance.

Increased Product Lifespan Dynamically tested adhesives exhibit improved durability and resistance to wear and tear.

Enhanced Safety Products designed with dynamic testing in mind are less likely to cause harm or injury.

Competitive Advantage By incorporating dynamic adhesive testing into your product development process, youll differentiate yourself from competitors.

QA Your Most Pressing Questions Answered

We understand that every manufacturer has unique questions and concerns. Here are some of the most frequently asked questions about Simulating mechanical stress and vibration

What types of products benefit from dynamic adhesive testing?

Any product exposed to dynamic forces, such as

Electronic devices (e.g., smartphones, laptops)

Automotive components (e.g., dashboards, interior trim)

Aerospace materials (e.g., satellite components, aircraft skin)

How do I know which type of testing is right for my product?

Consult with Eurolabs experts to determine the most suitable testing method based on your specific application and requirements.

Can you provide certification or documentation after the testing process?

Yes, upon completion of testing, well supply comprehensive reports detailing test results, recommendations, and any necessary certifications.

Is dynamic adhesive testing a one-time requirement or an ongoing process?

While initial testing is essential, regular re-testing may be necessary to ensure product performance remains optimal over time.

Conclusion Take the First Step Towards Unmatched Adhesive Performance

In todays fast-paced industry, manufacturers can no longer afford to overlook the importance of dynamic adhesive testing. By partnering with Eurolab and utilizing our Simulating mechanical stress and vibration service, youll be well on your way to creating products that meet the demands of even the most challenging environments.

Dont let product failure or costly rework hold you back take control of your adhesive performance today. Contact us to learn more about our comprehensive laboratory services and discover how dynamic testing can elevate your business to new heights.

-

Testing the ability of materials to adhere to surfaces without detaching or peeling

-

Evaluating the bond strength of adhesives used in construction materials and coatings

-

Testing whether adhesives maintain their integrity under stress, temperature changes, or environmental conditions

-

Simulating real-world conditions to test the durability of adhesive bonds over time

-

Ensuring that bonding agents used in construction materials such as tiles, paint, or flooring are durable

-

Testing for resistance to forces like shear, tension, and compression that could break the adhesive bond

-

Verifying that adhesive materials can withstand moisture, heat, and other environmental conditions

-

Testing the adhesion of coatings to substrates such as concrete, wood, or metal to ensure durability

-

Simulating heavy load conditions to test how adhesives perform under pressure or weight

-

Ensuring that adhesives used in outdoor and exposed construction applications remain stable

-

Verifying the adhesion of materials used for insulation, membranes, and coatings to various surfaces

-

Testing the peel strength of adhesives used in construction to ensure that bonds do not fail prematurely

-

Simulating the impact of thermal cycling on the adhesion of building materials over time

-

Testing for resistance to chemical exposure that could weaken or break adhesive bonds

-

Ensuring that adhesives maintain their performance under harsh conditions, such as high humidity or freezing temperatures

-

Verifying that adhesives used in joints and seams do not weaken or detach during building settlement or movement

-

Testing the adhesion of materials in construction panels to ensure stability over time

-

Ensuring that adhesives provide a consistent and strong bond without creating voids or bubbles

-

Verifying that adhesives do not cause material degradation or compromise structural integrity over time

-

Ensuring that adhesives used for floor and wall coverings provide secure bonding without excessive wear

-

Testing for any potential failure points in adhesive joints that could cause materials to separate over time

-

Ensuring that adhesives maintain their performance even after long exposure to weather or UV rays