Verifying the adhesion of materials used for insulation, membranes, and coatings to various surfaces

The Crucial Role of Verifying Adhesion in Ensuring Building Integrity A Laboratory Service by Eurolab

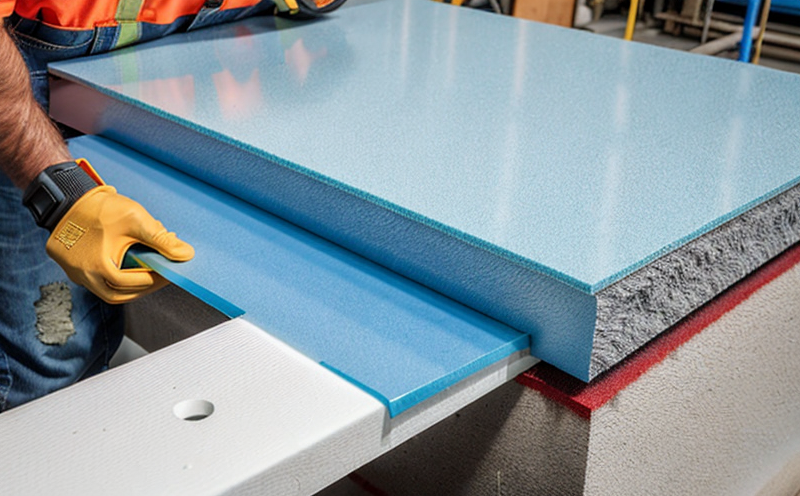

As the construction industry continues to evolve and prioritize sustainability, energy efficiency, and safety, the importance of verifying adhesion between materials used for insulation, membranes, and coatings has never been more critical. The adhesion of these materials to various surfaces is a crucial factor in determining their effectiveness, durability, and overall performance.

At Eurolab, our team of experts offers a comprehensive laboratory service designed specifically for this purpose Verifying the Adhesion of Materials Used for Insulation, Membranes, and Coatings to Various Surfaces. By partnering with us, businesses can ensure that their products meet stringent standards, comply with regulatory requirements, and provide maximum protection against environmental factors.

Why is Verifying Adhesion Essential for Businesses?

Inadequate adhesion between materials can lead to a host of problems, including

Reduced durability and lifespan

Increased risk of damage from weathering, temperature fluctuations, and other external factors

Compromised energy efficiency and insulation performance

Safety hazards due to potential structural weaknesses

By verifying the adhesion of their products, businesses can

Ensure compliance with building codes and regulations

Mitigate liability risks associated with product failure

Enhance customer trust and loyalty by guaranteeing superior quality and performance

Differentiate themselves from competitors through rigorous testing and validation

Key Benefits of Verifying Adhesion with Eurolab

Our laboratory service offers numerous benefits, including

Enhanced Product Performance Our expert analysis ensures that materials adhere to surfaces as intended, resulting in improved durability, energy efficiency, and overall performance.

Reduced Liability Risks By verifying adhesion, businesses can mitigate the risk of product failure, which can lead to costly lawsuits, damaged reputations, and lost revenue.

Improved Compliance Our services help ensure that products meet or exceed industry standards, regulatory requirements, and building codes.

Increased Customer Confidence Verified adhesion guarantees superior quality and performance, boosting customer trust and loyalty.

Competitive Advantage By partnering with Eurolab, businesses can differentiate themselves from competitors through rigorous testing and validation.

Comprehensive Laboratory Service

Our Verifying Adhesion service involves a range of specialized tests designed to assess the bond between materials used for insulation, membranes, and coatings. These include

Peel adhesion testing (e.g., ASTM D 3330)

Shear adhesion testing (e.g., ISO 4587)

Tensile adhesion testing (e.g., ISO 4624)

Adhesive properties analysis (e.g., tackiness, surface energy)

Our team of experts uses state-of-the-art equipment and follows international standards to ensure accurate and reliable results.

Frequently Asked Questions

Q What types of materials can be tested for adhesion?

A We test a wide range of materials used for insulation, membranes, and coatings, including polymers, elastomers, ceramics, and composites.

Q How long does the testing process take?

A The duration of our services depends on the specific tests required. However, we typically complete analyses within 1-5 working days.

Q What types of surfaces can be tested for adhesion?

A We test a variety of surfaces, including metals (e.g., steel, aluminum), plastics, wood, and concrete.

Q Can I request custom testing protocols or methods?

A Yes. Our team works closely with clients to develop customized testing plans tailored to their specific needs.

Q How do you ensure the accuracy and reliability of test results?

A We follow international standards (e.g., ASTM, ISO) and use calibrated equipment to guarantee precise and reliable results.

Conclusion

Verifying adhesion between materials used for insulation, membranes, and coatings is a critical step in ensuring building integrity and safety. At Eurolab, our comprehensive laboratory service provides businesses with the confidence that their products meet or exceed industry standards and regulatory requirements. By partnering with us, companies can enhance product performance, reduce liability risks, improve compliance, increase customer confidence, and gain a competitive advantage.

Dont compromise on adhesion testing choose Eurolab for expert analysis and reliable results. Contact us today to learn more about our Verifying Adhesion service.

-

Testing the ability of materials to adhere to surfaces without detaching or peeling

-

Evaluating the bond strength of adhesives used in construction materials and coatings

-

Testing whether adhesives maintain their integrity under stress, temperature changes, or environmental conditions

-

Simulating real-world conditions to test the durability of adhesive bonds over time

-

Ensuring that bonding agents used in construction materials such as tiles, paint, or flooring are durable

-

Testing for resistance to forces like shear, tension, and compression that could break the adhesive bond

-

Verifying that adhesive materials can withstand moisture, heat, and other environmental conditions

-

Testing the adhesion of coatings to substrates such as concrete, wood, or metal to ensure durability

-

Simulating heavy load conditions to test how adhesives perform under pressure or weight

-

Ensuring that adhesives used in outdoor and exposed construction applications remain stable

-

Testing the peel strength of adhesives used in construction to ensure that bonds do not fail prematurely

-

Simulating the impact of thermal cycling on the adhesion of building materials over time

-

Testing for resistance to chemical exposure that could weaken or break adhesive bonds

-

Ensuring that adhesives maintain their performance under harsh conditions, such as high humidity or freezing temperatures

-

Verifying that adhesives used in joints and seams do not weaken or detach during building settlement or movement

-

Testing the adhesion of materials in construction panels to ensure stability over time

-

Ensuring that adhesives provide a consistent and strong bond without creating voids or bubbles

-

Simulating mechanical stress and vibration to evaluate how adhesives perform in dynamic environments

-

Verifying that adhesives do not cause material degradation or compromise structural integrity over time

-

Ensuring that adhesives used for floor and wall coverings provide secure bonding without excessive wear

-

Testing for any potential failure points in adhesive joints that could cause materials to separate over time

-

Ensuring that adhesives maintain their performance even after long exposure to weather or UV rays