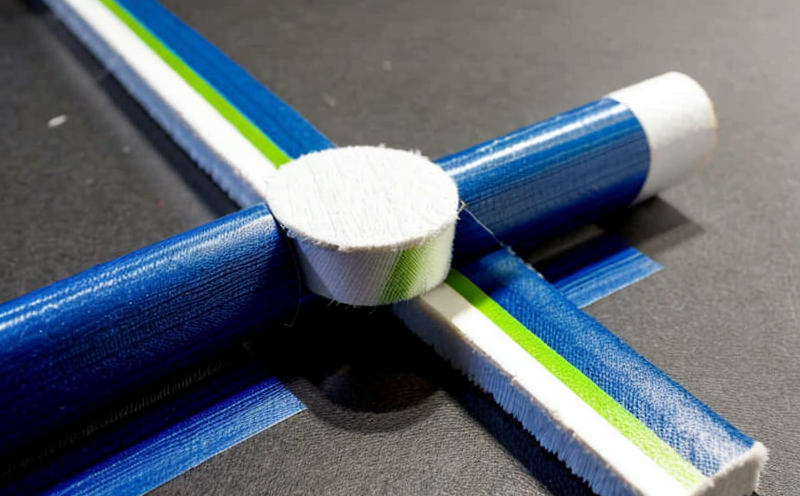

Testing for resistance to forces like shear, tension, and compression that could break the adhesive bond

The Crucial Role of Adhesive Bond Testing in Ensuring Product Integrity

In the world of manufacturing and product development, the adhesive bond is a critical component that holds various materials together. From consumer goods to industrial equipment, adhesives play a vital role in ensuring the structural integrity and performance of products. However, one question lingers How strong is the adhesive bond? Will it withstand forces like shear, tension, and compression that could potentially break it?

This is where Testing for resistance to forces like shear, tension, and compression that could break the adhesive bond comes into play a laboratory service provided by Eurolab. This testing procedure simulates real-world conditions to determine the adhesive bonds strength and durability under various loads.

In this article, we will delve into the importance of adhesive bond testing, its advantages, and the benefits it offers to businesses. Well also answer frequently asked questions about this crucial laboratory service.

Why Adhesive Bond Testing is Essential for Businesses

Adhesive bond testing is a critical step in ensuring product safety, performance, and reliability. With the increasing demand for quality products, manufacturers must guarantee that their adhesives can withstand various forces without compromising the integrity of their products. Failure to do so can result in costly recalls, damaged reputation, and even regulatory fines.

Some of the reasons why adhesive bond testing is essential for businesses include

Ensuring product safety Adhesive bond testing helps identify potential weaknesses in a products design or manufacturing process.

Improving product performance By determining an adhesives strength and durability, manufacturers can optimize their products performance and meet customer expectations.

Enhancing brand reputation Companies that invest in adhesive bond testing demonstrate their commitment to quality and reliability.

Advantages of Adhesive Bond Testing

Adhesive bond testing offers numerous benefits to businesses, including

Improved Product Reliability By simulating real-world conditions, manufacturers can identify potential weaknesses and improve the overall performance of their products.

Reduced Risk of Failure Adhesive bond testing helps minimize the risk of product failure, which can lead to costly recalls and damaged reputation.

Increased Efficiency Testing adhesives in a laboratory setting saves time and resources by identifying potential issues early on.

Enhanced Customer Satisfaction By guaranteeing product performance and reliability, manufacturers can meet customer expectations and increase satisfaction.

Some key benefits of adhesive bond testing include

Shear Testing Determines the adhesives resistance to shear forces, which can cause a bond to break apart.

Tension Testing Evaluates an adhesives ability to withstand tensile forces, such as stretching or pulling.

Compression Testing Simulates compressive forces that can cause adhesives to deform or fail.

How Adhesive Bond Testing Works

Eurolabs adhesive bond testing procedure involves a series of steps designed to simulate real-world conditions and determine an adhesives strength and durability. The process includes

Sample Preparation Adhesive samples are prepared according to specified protocols.

Loading Samples are subjected to various loads, including shear, tension, or compression forces.

Data Collection Data is collected using specialized equipment, such as tensiometers or load cells.

Analysis Results are analyzed to determine an adhesives strength and durability.

QA Section

Weve compiled a list of frequently asked questions about adhesive bond testing

Q What types of products require adhesive bond testing?

A Any product that uses adhesives, including consumer goods, industrial equipment, medical devices, and more.

Q How long does the testing process take?

A The duration varies depending on the type of test and sample preparation. Typically, it takes several days to a week or more for completion.

Q What types of loads are simulated during adhesive bond testing?

A Various loads, including shear, tension, and compression forces.

Q Can I request custom testing procedures?

A Yes, Eurolab offers customized testing procedures tailored to your specific needs.

Conclusion

Adhesive bond testing is a crucial step in ensuring product safety, performance, and reliability. By simulating real-world conditions, manufacturers can identify potential weaknesses and improve their products performance. Eurolabs laboratory service provides businesses with the assurance that their adhesives can withstand various forces without compromising product integrity.

Investing in adhesive bond testing not only enhances a companys reputation but also reduces the risk of failure and improves customer satisfaction. By choosing Eurolab, manufacturers can rest assured that their products meet industry standards and regulatory requirements.

Dont compromise on product safety and performance choose Eurolab for your adhesive bond testing needs today.

-

Testing the ability of materials to adhere to surfaces without detaching or peeling

-

Evaluating the bond strength of adhesives used in construction materials and coatings

-

Testing whether adhesives maintain their integrity under stress, temperature changes, or environmental conditions

-

Simulating real-world conditions to test the durability of adhesive bonds over time

-

Ensuring that bonding agents used in construction materials such as tiles, paint, or flooring are durable

-

Verifying that adhesive materials can withstand moisture, heat, and other environmental conditions

-

Testing the adhesion of coatings to substrates such as concrete, wood, or metal to ensure durability

-

Simulating heavy load conditions to test how adhesives perform under pressure or weight

-

Ensuring that adhesives used in outdoor and exposed construction applications remain stable

-

Verifying the adhesion of materials used for insulation, membranes, and coatings to various surfaces

-

Testing the peel strength of adhesives used in construction to ensure that bonds do not fail prematurely

-

Simulating the impact of thermal cycling on the adhesion of building materials over time

-

Testing for resistance to chemical exposure that could weaken or break adhesive bonds

-

Ensuring that adhesives maintain their performance under harsh conditions, such as high humidity or freezing temperatures

-

Verifying that adhesives used in joints and seams do not weaken or detach during building settlement or movement

-

Testing the adhesion of materials in construction panels to ensure stability over time

-

Ensuring that adhesives provide a consistent and strong bond without creating voids or bubbles

-

Simulating mechanical stress and vibration to evaluate how adhesives perform in dynamic environments

-

Verifying that adhesives do not cause material degradation or compromise structural integrity over time

-

Ensuring that adhesives used for floor and wall coverings provide secure bonding without excessive wear

-

Testing for any potential failure points in adhesive joints that could cause materials to separate over time

-

Ensuring that adhesives maintain their performance even after long exposure to weather or UV rays