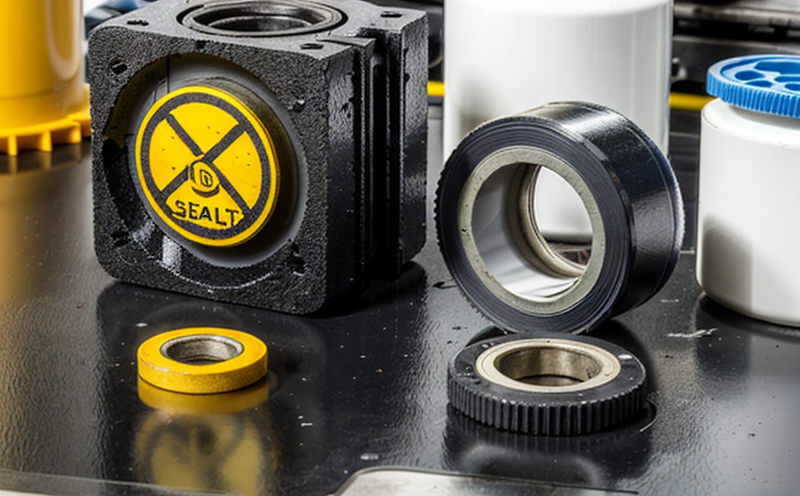

Testing for damage to packaging seals, labels, or other critical components after a drop event

The Hidden Dangers of Packaging Damage Why Testing for Critical Components after a Drop Event is Essential

As businesses navigate the complex landscape of supply chain management, product safety, and regulatory compliance, one critical aspect often flies under the radar packaging damage. A seemingly minor issue on the surface, damaged packaging can have far-reaching consequences that ripple throughout entire operations. From compromised product integrity to costly rework or even product recall, the stakes are high.

Thats where Eurolab comes in a leading laboratory service provider specializing in testing for damage to packaging seals, labels, or other critical components after a drop event. Our cutting-edge expertise and state-of-the-art facilities empower businesses like yours to identify and mitigate potential risks, ensuring compliance with industry standards and regulations.

What is Testing for Damage to Packaging Seals, Labels, or Other Critical Components after a Drop Event?

In essence, this laboratory service involves analyzing packaging components that have been subjected to a drop event whether its a shipping container falling off a pallet, a product being dropped during handling, or any other scenario where the packaging is compromised. Our team of experienced technicians employ advanced testing methods to assess damage severity and identify potential weaknesses.

This crucial evaluation process helps businesses

Verify packaging integrity Confirm that products remain secure and intact despite exposure to environmental stressors.

Comply with regulations Ensure adherence to industry standards, such as those set by the International Organization for Standardization (ISO) or relevant government agencies.

Mitigate product liability risks Identify potential issues before they become major concerns, protecting your brands reputation and bottom line.

The Advantages of Testing for Damage to Packaging Seals, Labels, or Other Critical Components after a Drop Event

Dont underestimate the importance of this laboratory service! Here are just a few key benefits

Reduced Product Liability Risks

Minimize potential financial losses due to product recalls or rework.

Safeguard your brands reputation by ensuring compliance with regulations.

Improved Packaging Design and Optimization

Receive expert analysis on packaging performance under various stress conditions.

Inform design changes that enhance overall packaging efficiency and effectiveness.

Enhanced Supply Chain Reliability

Verify that products are transported safely, reducing the risk of damage or loss.

Streamline logistics operations by identifying potential bottlenecks and inefficiencies.

Compliance with Industry Standards

Stay up-to-date on evolving regulatory requirements and industry best practices.

Demonstrate a commitment to quality and safety through rigorous testing and analysis.

Cost Savings through Proactive Risk Management

Identify and address issues early, preventing costly rework or product recalls.

Optimize packaging designs to minimize material waste and reduce shipping costs.

Frequently Asked Questions (FAQs)

We understand that you may have questions about our laboratory services. Below are some of the most common queries

Q What types of products can be tested for damage?

A Eurolabs testing services cover a wide range of products, including electronics, pharmaceuticals, cosmetics, food and beverages, and more.

Q How do I prepare my packaging samples for testing?

A Simply package your items according to standard procedures (e.g., sealing containers, attaching labels) and provide them to our laboratory team.

Q What methods are used to test packaging damage?

A Our experts employ a variety of advanced testing techniques, including drop impact testing, vibration analysis, and environmental stress screening.

Q How long does the testing process typically take?

A Turnaround times vary depending on sample volume and complexity. However, we strive to provide expedited services when needed.

Conclusion

Eurolabs laboratory service offering is designed to help businesses navigate the complex landscape of packaging damage and ensure compliance with industry standards. By leveraging our expertise in testing for critical components after a drop event, youll be well-equipped to

Reduce product liability risks

Enhance packaging design and optimization

Improve supply chain reliability

Comply with regulations

Achieve cost savings through proactive risk management

Dont wait until its too late trust Eurolab to provide the testing solutions you need to safeguard your products, protect your brand, and drive business success.

-

Simulating the impact of a drop from various heights to assess the durability of consumer product packaging

-

Testing the ability of packaging materials to withstand shock or impact during transportation

-

Verifying the strength and reliability of packaging designs to protect products from damage during handling

-

Assessing the resilience of fragile products like electronics, glassware, or cosmetics inside packaging

-

Simulating the conditions of product drops to test the performance of both inner and outer packaging layers

-

Evaluating the effectiveness of cushioning materials like foam or air pillows in protecting products during drops

-

Simulating drops on various surfaces (concrete, carpet, etc.) to assess the overall strength of packaging

-

Testing packaging for the ability to prevent contamination or exposure to the elements after a drop

-

Assessing the structural integrity of packaging boxes, bags, or containers under different drop conditions

-

Testing for leaks or breakage in packaging materials that hold liquids, powders, or fragile components

-

Evaluating the drop resistance of packaging used for consumer goods such as toys, appliances, or food products

-

Simulating multiple drop events to assess the long-term protection of packaging under continuous handling

-

Testing for punctures, cracks, or other forms of damage in packaging materials after impact tests

-

Verifying compliance with packaging standards and regulations to ensure products remain undamaged

-

Evaluating the performance of secondary packaging, such as protective films or wraps, during drop tests

-

Testing the ability of packaging to prevent the displacement or shifting of items during transit

-

Assessing whether packaging can protect products from being deformed or damaged due to high-impact forces

-

Simulating extreme drop conditions to assess packaging performance under worst-case scenarios

-

Verifying the ability of eco-friendly packaging materials to withstand drops without failure

-

Testing the resilience of packaging labels and printing after being subjected to drop-related stress