Testing for leaks or breakage in packaging materials that hold liquids, powders, or fragile components

Ensuring Packaging Integrity Why Testing for Leaks or Breakage Matters

As a business owner, youre well aware of the importance of packaging in protecting your products during transportation and storage. Whether its liquids, powders, or fragile components, packaging materials play a crucial role in maintaining product integrity. However, even with careful selection and handling, packaging can still fail, resulting in costly losses due to leakage, breakage, or other forms of damage.

This is where Testing for leaks or breakage in packaging materials that hold liquids, powders, or fragile components comes into play. At Eurolab, we offer a specialized laboratory service designed to simulate real-world conditions and assess the integrity of your packaging. By investing in this testing process, you can ensure that your products arrive at their destination safely and securely.

The Benefits of Testing for Leaks or Breakage

Incorporating leak and breakage testing into your quality control protocol offers numerous advantages, including

Reduced Product Loss Leak testing helps identify faulty packaging before its shipped out, minimizing the risk of product loss due to leakage or damage during transit.

Improved Customer Satisfaction When products arrive at their destination intact, customers are more likely to be satisfied with their purchase. This leads to increased customer loyalty and retention rates.

Compliance with Regulations Many industries have specific regulations regarding packaging standards. Leak testing helps ensure that your products meet these requirements, reducing the risk of fines or penalties.

Cost Savings Identifying faulty packaging before its used saves time and resources that would be spent on replacing or repairing damaged products.

Enhanced Brand Reputation Companies that prioritize product safety and integrity build trust with their customers, which can lead to increased brand loyalty and advocacy.

Increased Efficiency Leak testing streamlines the quality control process, allowing you to focus on other aspects of your business while ensuring that your packaging meets industry standards.

How Eurolabs Testing Services Work

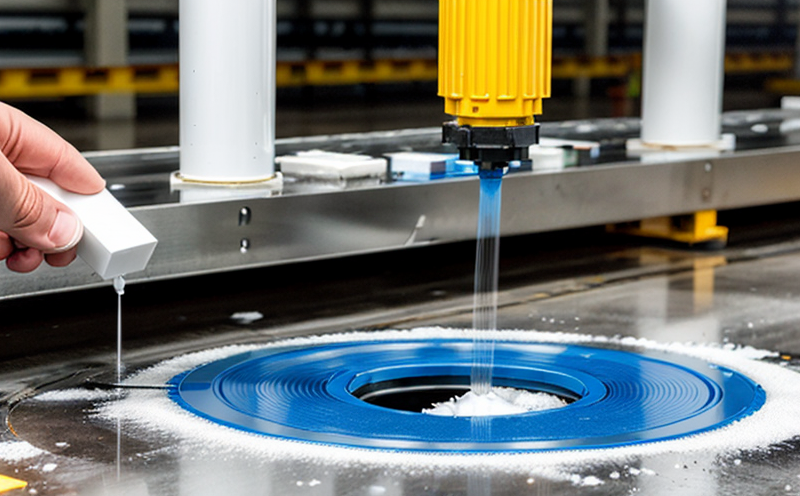

Our laboratory is equipped with state-of-the-art equipment designed to simulate real-world conditions. Our experienced technicians use a variety of methods to test for leaks or breakage in packaging materials, including

Drop Testing Products are dropped from various heights to assess the structural integrity of their packaging.

Vibration Testing Packaging is subjected to controlled vibrations to evaluate its ability to withstand movement and impact.

Pressure Testing Liquids or gases are introduced into packaging containers to check for leaks or other forms of damage.

Environmental Testing Packaging is exposed to various environmental conditions, such as temperature fluctuations, humidity, or exposure to chemicals, to assess its durability.

QA Frequently Asked Questions

What types of products can be tested?

At Eurolab, we test a wide range of packaging materials that hold liquids, powders, or fragile components. This includes bottles, cans, jars, tubes, and other containers used for cosmetics, pharmaceuticals, food products, chemicals, and more.

How long does the testing process take?

The length of time required for testing varies depending on the type of product and test method used. However, our laboratory is equipped to perform multiple tests simultaneously, ensuring that your products are tested efficiently and effectively.

What kind of equipment do you use for testing?

We utilize state-of-the-art equipment designed specifically for leak and breakage testing, including drop testers, vibration machines, pressure chambers, and environmental simulation units.

Can I witness the testing process?

Yes. We encourage our clients to observe the testing process to gain a better understanding of how their products are being evaluated. This also provides an opportunity for any questions or concerns you may have to be addressed directly by our technicians.

What kind of reports do you provide after testing?

After completing the testing process, we provide detailed reports outlining the results of each test. These reports include photographs, videos, and a comprehensive summary of the findings, making it easy to share with stakeholders or regulatory bodies.

Invest in Packaging Integrity Today

At Eurolab, we understand the importance of packaging integrity in protecting your products during transportation and storage. By investing in leak and breakage testing, you can ensure that your business is operating efficiently, safely, and compliantly. Contact us today to learn more about our laboratory services and how we can help you safeguard your products.

Additional Resources

For more information on the importance of packaging integrity or to discuss your specific testing needs, please visit our website for additional resources, including case studies, whitepapers, and industry insights.

In conclusion, Testing for leaks or breakage in packaging materials that hold liquids, powders, or fragile components is a critical aspect of product safety and quality control. By incorporating this laboratory service into your business practices, you can minimize product loss, improve customer satisfaction, comply with regulations, save costs, enhance brand reputation, and increase efficiency.

Dont let faulty packaging compromise the integrity of your products. Partner with Eurolab today to ensure that your packaging meets industry standards and protects your investment in every way possible.

-

Simulating the impact of a drop from various heights to assess the durability of consumer product packaging

-

Testing the ability of packaging materials to withstand shock or impact during transportation

-

Verifying the strength and reliability of packaging designs to protect products from damage during handling

-

Assessing the resilience of fragile products like electronics, glassware, or cosmetics inside packaging

-

Simulating the conditions of product drops to test the performance of both inner and outer packaging layers

-

Testing for damage to packaging seals, labels, or other critical components after a drop event

-

Evaluating the effectiveness of cushioning materials like foam or air pillows in protecting products during drops

-

Simulating drops on various surfaces (concrete, carpet, etc.) to assess the overall strength of packaging

-

Testing packaging for the ability to prevent contamination or exposure to the elements after a drop

-

Assessing the structural integrity of packaging boxes, bags, or containers under different drop conditions

-

Evaluating the drop resistance of packaging used for consumer goods such as toys, appliances, or food products

-

Simulating multiple drop events to assess the long-term protection of packaging under continuous handling

-

Testing for punctures, cracks, or other forms of damage in packaging materials after impact tests

-

Verifying compliance with packaging standards and regulations to ensure products remain undamaged

-

Evaluating the performance of secondary packaging, such as protective films or wraps, during drop tests

-

Testing the ability of packaging to prevent the displacement or shifting of items during transit

-

Assessing whether packaging can protect products from being deformed or damaged due to high-impact forces

-

Simulating extreme drop conditions to assess packaging performance under worst-case scenarios

-

Verifying the ability of eco-friendly packaging materials to withstand drops without failure

-

Testing the resilience of packaging labels and printing after being subjected to drop-related stress