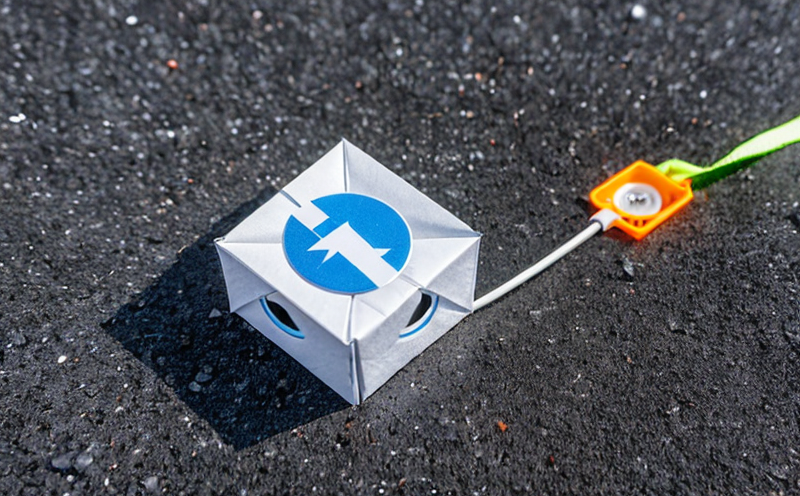

Testing packaging for the ability to prevent contamination or exposure to the elements after a drop

The Crucial Role of Testing Packaging for Contamination Prevention Why Your Business Needs Eurolabs Expertise

In todays fast-paced and highly competitive business landscape, companies are constantly seeking innovative ways to improve product quality, reduce costs, and enhance brand reputation. One often-overlooked yet critical aspect of ensuring product integrity is packaging testing specifically, the ability to prevent contamination or exposure to the elements after a drop. This specialized laboratory service, offered by Eurolab, is designed to simulate real-world scenarios, providing businesses with invaluable insights into their packagings performance.

What is Testing Packaging for Contamination Prevention?

Testing packaging for the ability to prevent contamination or exposure to the elements after a drop involves subjecting products to rigorous and controlled conditions that mimic the effects of accidental drops, spills, or environmental stressors. This laboratory service employs advanced equipment and techniques to evaluate packaging materials resistance to damage, leakage, or other forms of degradation.

Why is Testing Packaging for Contamination Prevention Essential for Businesses?

Product Safety Preventing contamination and exposure to the elements after a drop ensures consumer safety and compliance with regulatory requirements.

Brand Reputation Demonstrating a commitment to product integrity and quality reinforces your brands reputation, fostering trust among customers and stakeholders.

Cost Savings Identifying packaging vulnerabilities early on can help reduce costs associated with returns, refunds, or even lawsuits related to faulty products.

Innovation and Competitiveness Investing in testing and improvement of packaging materials sets your business apart from competitors, showcasing a dedication to innovation and excellence.

Advantages of Using Eurolabs Testing Packaging Services

Enhanced Product Integrity Our expert analysis provides actionable insights into packaging performance under various conditions.

Reduced Risk of Contamination Identify potential vulnerabilities and develop strategies to minimize risks of contamination or exposure to the elements after a drop.

Increased Efficiency Streamline your supply chain by selecting materials that meet specific standards, reducing time-to-market and waste.

Cost Savings Avoid costly rework or redesigns by identifying packaging issues early on.

Key Benefits of Eurolabs Testing Packaging Services

Objective Evaluation Our unbiased testing procedures ensure accurate results, eliminating any potential conflicts of interest.

Comprehensive Reporting Receive detailed reports highlighting strengths and weaknesses in your packaging materials.

Customized Solutions Collaborate with our experts to develop tailored solutions addressing specific business needs.

Scalability As your business grows, Eurolabs testing services adapt to meet increasing demands.

Eurolabs Testing Packaging Services A Closer Look

Our state-of-the-art laboratory is equipped with cutting-edge equipment and staffed by experienced professionals dedicated to delivering exceptional results. With our extensive range of testing protocols, we can evaluate packaging materials under various conditions, including

Drop testing (simulating accidental drops from different heights)

Vibration testing (assessing resistance to vibrations and shocks)

Compression testing (evaluating impact resistance and seal integrity)

Frequently Asked Questions

Q What types of products benefit from Testing packaging for contamination prevention?

A Any product that requires protection against environmental stressors or accidental damage, such as electronics, pharmaceuticals, cosmetics, food and beverage items, and more.

Q How long does the testing process typically take?

A The duration of our testing services varies depending on the complexity of the project. However, most tests can be completed within a few days to several weeks.

Q Are your testing protocols compliant with industry standards?

A Yes, Eurolabs testing protocols meet or exceed international standards for packaging and material testing.

Q Can I collaborate with your experts to develop customized testing solutions?

A Absolutely! Our team is dedicated to providing tailored services that cater to specific business needs.

-

Simulating the impact of a drop from various heights to assess the durability of consumer product packaging

-

Testing the ability of packaging materials to withstand shock or impact during transportation

-

Verifying the strength and reliability of packaging designs to protect products from damage during handling

-

Assessing the resilience of fragile products like electronics, glassware, or cosmetics inside packaging

-

Simulating the conditions of product drops to test the performance of both inner and outer packaging layers

-

Testing for damage to packaging seals, labels, or other critical components after a drop event

-

Evaluating the effectiveness of cushioning materials like foam or air pillows in protecting products during drops

-

Simulating drops on various surfaces (concrete, carpet, etc.) to assess the overall strength of packaging

-

Assessing the structural integrity of packaging boxes, bags, or containers under different drop conditions

-

Testing for leaks or breakage in packaging materials that hold liquids, powders, or fragile components

-

Evaluating the drop resistance of packaging used for consumer goods such as toys, appliances, or food products

-

Simulating multiple drop events to assess the long-term protection of packaging under continuous handling

-

Testing for punctures, cracks, or other forms of damage in packaging materials after impact tests

-

Verifying compliance with packaging standards and regulations to ensure products remain undamaged

-

Evaluating the performance of secondary packaging, such as protective films or wraps, during drop tests

-

Testing the ability of packaging to prevent the displacement or shifting of items during transit

-

Assessing whether packaging can protect products from being deformed or damaged due to high-impact forces

-

Simulating extreme drop conditions to assess packaging performance under worst-case scenarios

-

Verifying the ability of eco-friendly packaging materials to withstand drops without failure

-

Testing the resilience of packaging labels and printing after being subjected to drop-related stress