Unlocking Accurate Measurements The Power of 3D Profilometry Scanning with Eurolab

In todays fast-paced business landscape, staying ahead of the competition requires more than just innovative products and services it demands precision and accuracy in every aspect of operations. For industries such as manufacturing, quality control, and research and development, accurate measurements are crucial for product design, production optimization, and defect detection. This is where 3D profilometry scanning comes into play, a cutting-edge laboratory service offered by Eurolab that revolutionizes measurement technology.

What is 3D Profilometry Scanning?

3D profilometry scanning is a non-contact, high-precision technique used to capture the surface topography of an object in three dimensions. By employing advanced sensors and sophisticated algorithms, this method provides detailed profiles of the objects shape, allowing for accurate measurements, analysis, and comparison. Unlike traditional contact methods, 3D profilometry scanning does not damage or alter the object being measured, making it a versatile tool across various industries.

Why is 3D Profilometry Scanning Essential for Businesses?

The advantages of using 3D profilometry scanning in your business are multifaceted and substantial. Heres a detailed breakdown

Key Benefits

Accuracy 3D profilometry scanning offers unparalleled accuracy, reducing measurement errors and ensuring that data is reliable.

Speed The process is remarkably fast, allowing for quick turnaround times and minimizing downtime.

Non-Destructive Testing Unlike traditional methods, it does not damage or alter the object being measured.

Multi-Angle Analysis Captures detailed profiles from various angles, providing a comprehensive understanding of an objects surface topography.

Material Inspection Useful for inspecting the micro-structure of materials to identify defects and flaws.

Quality Control Enables businesses to set precise standards for product quality and performance.

Advantages in Different Industries

3D profilometry scanning has far-reaching applications across various sectors, offering specific benefits tailored to each industrys unique needs

Manufacturing Enhances product design and production optimization by providing detailed measurements of surface topography.

Quality Control Ensures precise standards for product quality and performance.

Research and Development Facilitates innovation in fields such as material science, mechanical engineering, and more.

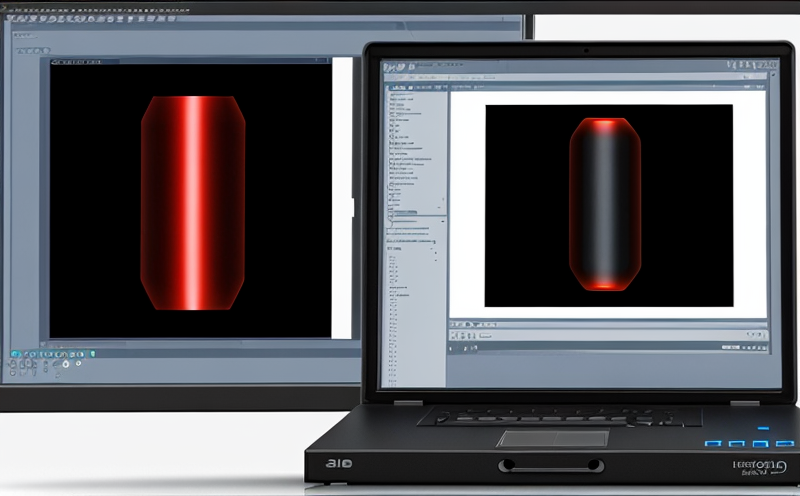

How 3D Profilometry Scanning Works

The process involves several steps

Preparation of the object being measured.

Setting up the scanning equipment according to specific requirements.

Conducting the scanning procedure, which may involve capturing multiple angles or views.

Processing and analyzing the captured data.

QA Your Questions Answered

Q Is 3D profilometry scanning a contact method?

A No, it is non-contact, ensuring that your objects are not damaged during measurement.

Q How accurate is 3D profilometry scanning compared to traditional methods?

A Significantly more accurate, with reduced measurement errors and reliable data.

Q Can I use 3D profilometry scanning for inspecting materials?

A Yes, its useful for inspecting the micro-structure of materials to identify defects and flaws.

Trust Eurolab for Your 3D Profilometry Scanning Needs

At Eurolab, we pride ourselves on delivering cutting-edge laboratory services that meet the most stringent demands. With our state-of-the-art equipment and expert team, you can trust us to provide accurate measurements and comprehensive analysis. Dont settle for anything less choose the best and unlock the full potential of your business with 3D profilometry scanning from Eurolab.