The Crucial Role of Edge Surface Roughness in Ensuring Product Quality

In the world of manufacturing and production, precision is key to delivering high-quality products that meet customer expectations. One critical aspect of ensuring product quality is edge surface roughness, a laboratory service provided by Eurolab. But what exactly is edge surface roughness, and why is it essential for businesses? In this article, we will delve into the world of edge surface roughness, exploring its significance, benefits, and how our expert team at Eurolab can help you achieve superior product quality.

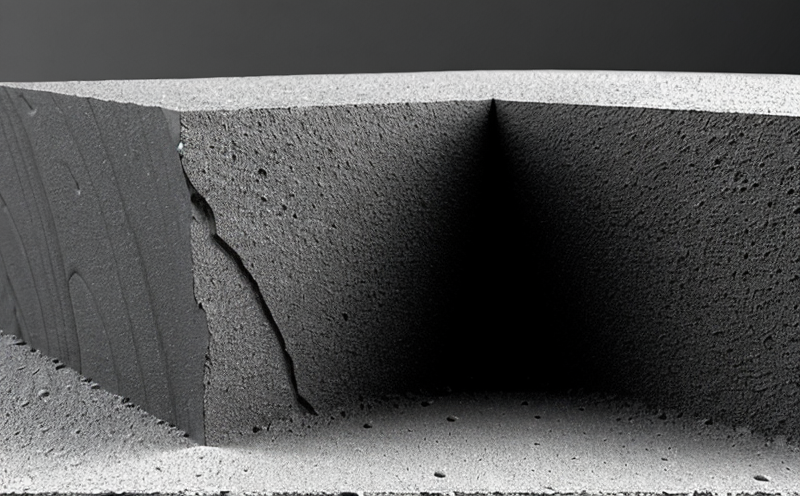

What is Edge Surface Roughness?

Edge surface roughness refers to the measurement of the roughness or smoothness of a materials edge. It is an essential parameter in determining the quality of a product, particularly in industries such as aerospace, automotive, and medical devices. A high-quality edge surface requires a precise balance between smoothness and roughness, ensuring that it meets specific industry standards.

Why is Edge Surface Roughness Crucial for Businesses?

In todays competitive market, businesses must adhere to strict quality control measures to ensure product reliability and performance. Edge surface roughness plays a vital role in this process by

Ensuring compliance with industry regulations

Enhancing product safety and reliability

Improving production efficiency and reducing waste

Reducing costs associated with rework or replacement

The Advantages of Using Eurolabs Edge Surface Roughness Service

By partnering with Eurolab for edge surface roughness testing, businesses can enjoy numerous benefits that contribute to their growth and success. Some of these advantages include

Improved Product Quality Our expert team at Eurolab utilizes state-of-the-art equipment to provide accurate and reliable measurements, ensuring your products meet the highest quality standards.

Enhanced Customer Satisfaction With precise edge surface roughness measurements, you can rest assured that your products will meet customer expectations, leading to increased satisfaction and loyalty.

Reduced Costs By identifying potential issues early on, our testing services help minimize rework or replacement costs, saving you time and resources.

Increased Efficiency Our streamlined testing process enables quick turnaround times, allowing you to get back to production without delays.

Compliance with Industry Regulations Our expert team ensures that your products meet specific industry standards, minimizing the risk of non-compliance and associated penalties.

How Does Edge Surface Roughness Testing Work?

At Eurolab, we employ advanced techniques and equipment to accurately measure edge surface roughness. The process typically involves

Sampling Collecting a representative sample from the production line.

Preparation Preparing the sample for testing by cleaning or etching it as required.

Measurement Utilizing specialized equipment, such as profilometers or interferometers, to measure the edge surface roughness.

Analysis Interpreting the data and providing a detailed report on the edge surface roughness.

QA Frequently Asked Questions About Edge Surface Roughness

At Eurolab, we understand that you may have questions about our edge surface roughness service. Below are some frequently asked questions that provide insight into our testing process

Q What is the purpose of edge surface roughness testing?

A The primary goal of edge surface roughness testing is to ensure that products meet specific industry standards and regulations, ensuring product quality and reliability.

Q How do you measure edge surface roughness?

A We utilize advanced equipment, such as profilometers or interferometers, to accurately measure the edge surface roughness.

Q What types of industries benefit from edge surface roughness testing?

A Various industries, including aerospace, automotive, medical devices, and more, can benefit from our edge surface roughness service.

Q How long does the testing process typically take?

A Our streamlined testing process enables quick turnaround times, usually within 24-48 hours.

Conclusion

In conclusion, edge surface roughness is a critical aspect of product quality that cannot be overlooked. By partnering with Eurolab for our edge surface roughness service, businesses can ensure compliance with industry regulations, enhance product safety and reliability, improve production efficiency, and reduce costs associated with rework or replacement. Our expert team at Eurolab is dedicated to providing accurate and reliable measurements, helping you achieve superior product quality that meets the highest standards.

Dont compromise on product quality choose Eurolab for your edge surface roughness testing needs today!