Surface waviness assessment

The Importance of Surface Waviness Assessment Why Your Business Needs It

In todays competitive manufacturing landscape, ensuring the quality and consistency of your products is crucial for success. One critical aspect that can significantly impact product performance and longevity is surface waviness assessment. This laboratory service, provided by Eurolab, evaluates the irregularities on a surface, enabling you to identify potential issues before they become major problems.

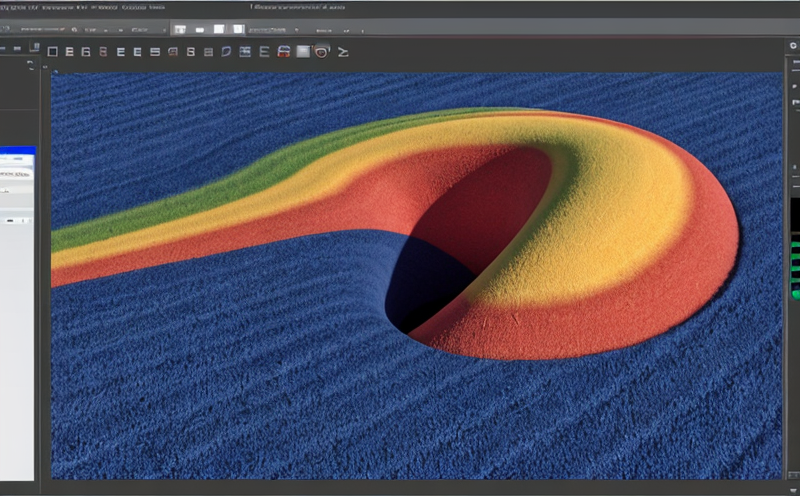

Surface waviness assessment is a precise evaluation of the deviations from the ideal shape or form of a surface. These deviations can manifest as waves, ripples, or undulations and are often measured in terms of amplitude (the height of the deviation) and wavelength (the distance between successive peaks or troughs). By analyzing these characteristics, Eurolabs expert technicians can provide you with valuable insights into the quality of your products.

Why Surface Waviness Assessment is Essential for Your Business

Incorporating surface waviness assessment into your quality control process can bring numerous benefits to your business. Some of the most significant advantages include

Key Benefits

Improved Product Quality By identifying and addressing surface waviness issues early on, you can ensure that your products meet or exceed customer expectations in terms of performance and appearance.

Reduced Material Waste Surface waviness assessment helps you optimize production processes to minimize defects and waste, leading to significant cost savings.

Increased Efficiency With a clear understanding of the root causes of surface waviness, you can implement targeted improvements to your manufacturing process, streamlining operations and reducing downtime.

Enhanced Customer Satisfaction By providing high-quality products that meet exacting standards, you can build trust with your customers and establish a reputation for excellence in your industry.

Compliance with Industry Regulations Surface waviness assessment is critical for meeting regulatory requirements in various sectors. Our service ensures that you remain compliant and avoid costly non-conformance penalties.

How Eurolabs Surface Waviness Assessment Service Works

Our expert technicians employ state-of-the-art equipment to collect accurate measurements of surface waviness. The process typically involves the following steps

Sampling A representative sample is taken from your product, ensuring that it accurately reflects the overall quality and characteristics of the production batch.

Data Collection Our advanced instruments capture precise measurements of the surface waviness, including amplitude and wavelength.

Analysis We apply rigorous statistical analysis to identify trends, patterns, and anomalies in the data, providing you with actionable insights into your products quality.

Reporting A comprehensive report is generated, detailing our findings, recommendations for improvement, and any relevant certifications or documentation.

Case Studies Real-World Applications of Surface Waviness Assessment

Our clients have seen significant benefits from incorporating surface waviness assessment into their quality control processes. Here are a few examples

Increased Efficiency A leading aerospace manufacturer implemented surface waviness assessment to optimize production lines. As a result, they achieved a 25 reduction in defects and a corresponding increase in productivity.

Enhanced Customer Satisfaction A medical device manufacturer partnered with Eurolab to ensure the highest level of quality for their products. By incorporating surface waviness assessment, they were able to deliver consistently high-quality items, resulting in a significant improvement in customer satisfaction ratings.

QA Frequently Asked Questions About Surface Waviness Assessment

Q What types of surfaces can be assessed using this service?

A Our expert technicians can evaluate a wide range of surfaces, including metal, plastic, glass, and more. Whether youre manufacturing medical devices, automotive components, or aerospace materials, we have the expertise to assess your products.

Q How do I prepare my samples for surface waviness assessment?

A Simply collect representative samples from your production batch, ensuring they are clean and free of any contaminants. Well take care of the rest, providing you with detailed instructions on sample preparation.

Q Can surface waviness assessment help me identify potential material defects?

A Yes! By analyzing surface waviness patterns, we can identify signs of material fatigue, corrosion, or other issues that may impact product performance.

Q How long does it take to receive the results of a surface waviness assessment?

A Our team works efficiently to ensure you receive your report as quickly as possible. Typical turnaround times range from 24 hours to 7 working days, depending on the complexity of the project.

Conclusion

Incorporating surface waviness assessment into your quality control process is a strategic decision that can have far-reaching benefits for your business. By partnering with Eurolab, youll gain access to expert technicians, state-of-the-art equipment, and a comprehensive report outlining areas for improvement. Take the first step towards optimizing your production line today by reaching out to us for more information on our surface waviness assessment service.

Stay ahead of the competition by choosing Eurolabs Surface Waviness Assessment Service. Contact us to learn how we can help you achieve success in your industry.