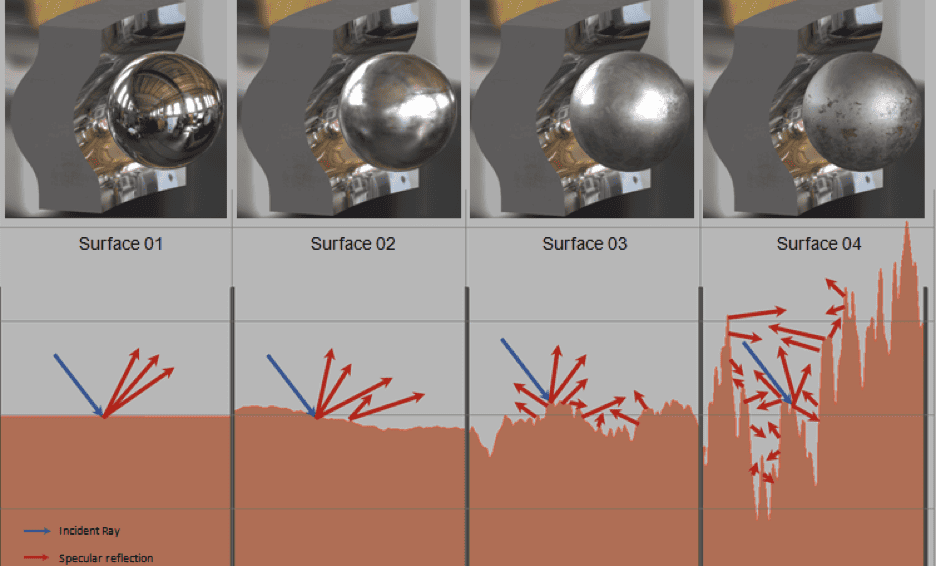

Roughness profile comparison

Unlock the Secrets of Your Materials Why Roughness Profile Comparison is a Game-Changer for Businesses

In todays fast-paced manufacturing world, understanding the intricate characteristics of materials is crucial for businesses to stay ahead of the competition. Among these characteristics, surface roughness plays a pivotal role in determining the performance and lifespan of products. Roughness profile comparison is a laboratory service provided by Eurolab that allows businesses to accurately assess the surface texture of their materials, making informed decisions about product development, quality control, and material selection.

In this article, well delve into the importance of roughness profile comparison, its numerous advantages, and how it can revolutionize your businesss material evaluation process. Whether youre a manufacturer, engineer, or quality assurance specialist, understanding the benefits of roughness profile comparison will help you optimize your operations and improve product performance.

What is Roughness Profile Comparison?

Roughness profile comparison involves analyzing the surface topography of materials using advanced techniques such as profilometry, interferometry, and atomic force microscopy. These methods provide detailed measurements of surface roughness parameters, including Ra (average roughness), Rz (ten-point mean roughness), and Rq (root mean square roughness). By comparing these parameters across different samples or batches, businesses can identify patterns, trends, and correlations between surface texture and product performance.

The Advantages of Roughness Profile Comparison

Eurolabs Roughness profile comparison service offers a wide range of benefits that can transform your business. Here are just a few

Improved Product Quality and Reliability

Accurately assess the surface roughness of materials to ensure compliance with industry standards

Identify and mitigate defects, such as scratches or corrosion, that can compromise product performance

Optimize material selection for specific applications, reducing the risk of premature wear or failure

Enhanced Material Selection and Optimization

Compare the surface roughness of different materials to determine their suitability for various applications

Identify correlations between surface texture and mechanical properties, such as hardness or toughness

Develop predictive models to forecast material performance based on surface roughness data

Increased Efficiency and Cost Savings

Reduce the time and resources required for material evaluation and quality control

Minimize rework and scrap rates by identifying and addressing surface roughness issues early on

Improve supply chain management by selecting materials with consistent, predictable surface textures

Better Decision-Making and Data-Driven Insights

Gain a deeper understanding of the complex relationships between surface roughness and product performance

Develop data-driven strategies to optimize material selection, processing conditions, and quality control protocols

Stay ahead of competitors by leveraging Eurolabs expert analysis and cutting-edge technology

Compliance with Industry Standards and Regulations

Ensure compliance with industry standards, such as ISO 4287 or ASTM E18-16

Meet regulatory requirements for product safety and performance

Maintain a competitive edge by demonstrating commitment to quality and excellence

Frequently Asked Questions

Q What types of materials can be analyzed using roughness profile comparison?

A Eurolabs service is suitable for a wide range of materials, including metals, polymers, ceramics, and composites.

Q How does the analysis process work?

A Our expert technicians use advanced equipment to collect data on surface roughness parameters. The results are then analyzed and compared using specialized software.

Q What is the typical turnaround time for roughness profile comparison services?

A Turnaround times vary depending on the complexity of the project, but most analyses can be completed within 1-3 working days.

Q Can I request a customized analysis or specific parameters to be measured?

A Absolutely! Our team works closely with clients to understand their unique requirements and develop tailored analysis plans.

Q Is my data secure and confidential?

A Eurolab is committed to maintaining the confidentiality and security of client data. All results are presented in a clear, concise manner, ensuring easy interpretation and decision-making.

Get Started with Eurolabs Expert Roughness Profile Comparison Services

Dont let surface roughness issues compromise your businesss success. Contact us today to learn more about our Roughness profile comparison services and how we can help you unlock the full potential of your materials. With our expert analysis, cutting-edge technology, and commitment to quality, youll be able to make informed decisions with confidence.

At Eurolab, were dedicated to providing world-class laboratory services that support business growth and innovation. Trust us to guide you through the complexities of material evaluation and surface roughness analysis, empowering you to take your products and processes to new heights.