Adhesion performance in coatings under mechanical stress

The Crucial Role of Adhesion Performance in Coatings under Mechanical Stress Why Businesses Must Invest

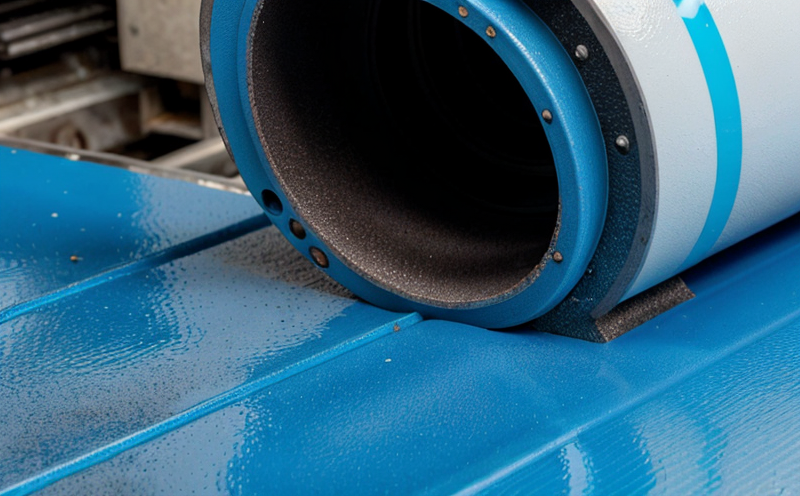

As a leading manufacturer or processor of various products, you understand the importance of coatings and their ability to withstand the rigors of mechanical stress. A coatings adhesion performance is crucial in determining its overall effectiveness and longevity on your product. When subjected to mechanical stress, coatings can fail to adhere properly, leading to reduced lifespan, decreased functionality, and compromised safety.

At Eurolab, we specialize in providing laboratory services that help businesses like yours evaluate the adhesion performance of their coatings under mechanical stress. Our state-of-the-art facilities and expert technicians ensure that your products are subjected to rigorous testing protocols, providing you with accurate data on how well they perform under real-world conditions.

Why Adhesion Performance is Essential for Businesses

Adhesion performance in coatings under mechanical stress is a critical factor in various industries, including

Aerospace Coatings on aircraft components must withstand extreme temperatures, vibrations, and exposure to chemicals.

Automotive Car manufacturers rely on durable coatings to protect surfaces from corrosion, fading, and wear.

Medical Devices Medical implants and equipment require coatings that resist biocompatibility issues and maintain their adhesion under stress.

Failure to meet these demands can result in costly recalls, production delays, and compromised product safety. By testing the adhesion performance of your coatings, you can

Advantages of Using Adhesion Performance Testing

Eurolabs laboratory services offer numerous benefits that set us apart from other providers

Improved Product Quality Accurate data on coating adhesion ensures that your products meet industry standards and regulatory requirements.

Increased Product Lifespan By identifying areas for improvement, you can extend the lifespan of your coatings and reduce maintenance costs.

Enhanced Brand Reputation Demonstrating a commitment to quality and safety through rigorous testing protocols enhances your brands reputation among customers and stakeholders.

Reduced Liability Risks Testing coatings under mechanical stress helps mitigate liability risks associated with product failures or recalls.

Key Benefits of Adhesion Performance in Coatings Under Mechanical Stress

Our services offer the following key benefits

Standardized Testing Protocols Our expert technicians follow internationally recognized testing standards to ensure accuracy and reproducibility.

High-Sensitivity Equipment Advanced equipment, such as dynamic mechanical analyzers (DMA), enables precise measurement of coating adhesion under various stress conditions.

Customizable Testing Options We offer tailored test plans to accommodate your specific product requirements and industry regulations.

Comprehensive Data Analysis Expert analysis and reporting ensure that you receive actionable insights to inform future development and production decisions.

Frequently Asked Questions

Q What types of coatings can be tested for adhesion performance?

A Eurolab tests a wide range of coatings, including paints, primers, varnishes, and thin films.

Q How do I prepare my products for testing?

A Our expert technicians will guide you through the preparation process to ensure that your products are ready for testing.

Q What types of mechanical stress can be simulated in the laboratory?

A We simulate various forms of mechanical stress, including peel, scratch, and impact.

Q How do I interpret the test results provided by Eurolab?

A Our expert technicians will provide a comprehensive report explaining the test results and recommendations for improvement.

Conclusion

In todays competitive business landscape, investing in adhesion performance testing is no longer optional its essential. By partnering with Eurolab, you can ensure that your coatings meet industry standards and regulatory requirements, reducing liability risks and improving product quality.

Dont compromise on coating performance. Choose the experts at Eurolab for accurate, reliable, and actionable data that drives informed decision-making in your organization.