Adhesion strength testing under thermal cycling conditions

Unveiling the Secrets of Adhesion Strength Why Thermal Cycling Testing Matters for Your Business

In todays fast-paced manufacturing landscape, ensuring the reliability and performance of materials is crucial for businesses seeking to stay ahead of the competition. One critical aspect that often goes overlooked is adhesion strength testing under thermal cycling conditions. At Eurolab, we specialize in providing laboratory services that help companies like yours evaluate the adhesion properties of their materials, exposing them to the harsh realities of temperature fluctuations.

What is Adhesion Strength Testing Under Thermal Cycling Conditions?

Adhesion strength testing under thermal cycling conditions is a comprehensive evaluation of how well a material adheres to its substrate when subjected to repeated cycles of heating and cooling. This laboratory service simulates real-world scenarios where materials are exposed to varying temperatures, such as those encountered in automotive, aerospace, or construction applications. By testing adhesion under these conditions, companies can identify potential weaknesses in their products and make informed decisions about material selection, design optimization, and manufacturing processes.

The Importance of Adhesion Strength Testing Under Thermal Cycling Conditions

Adhesion strength testing under thermal cycling conditions is more than just a laboratory service its a business enabler. Here are the key advantages of using this type of testing

Advantages of Using Adhesion Strength Testing Under Thermal Cycling Conditions

Improved Product Reliability By simulating real-world temperature fluctuations, companies can ensure that their products perform consistently and reliably in various environments.

Reduced Warranty Claims Testing adhesion under thermal cycling conditions helps manufacturers identify potential weaknesses before products reach the market, minimizing warranty claims and associated costs.

Enhanced Material Selection Companies can make informed decisions about material selection by evaluating the adhesion properties of different materials under various temperature conditions.

Design Optimization Adhesion strength testing under thermal cycling conditions enables designers to optimize product designs for improved performance and reduced failure rates.

Compliance with Industry Standards Eurolabs laboratory services are designed to meet or exceed industry standards, ensuring that your products comply with regulatory requirements.

Benefits of Partnering with Eurolab

Expertise Our team of experienced scientists and engineers provides specialized knowledge in materials science and testing.

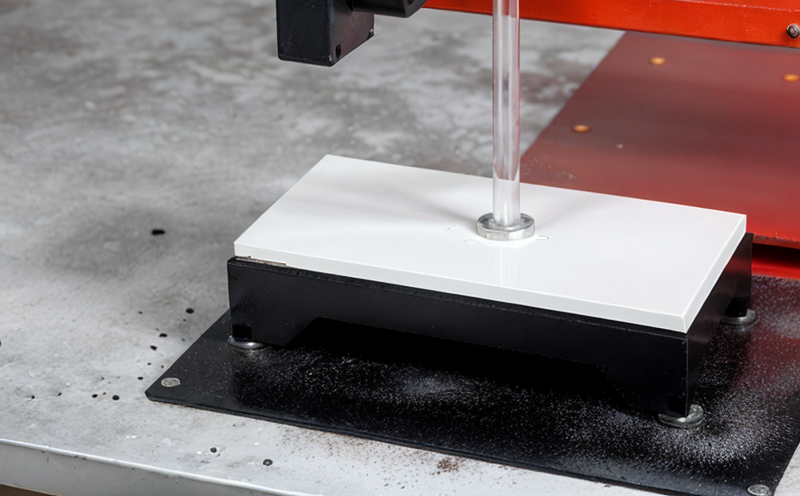

State-of-the-Art Equipment We utilize cutting-edge equipment to simulate real-world temperature fluctuations and evaluate adhesion strength accurately.

Customized Testing Programs We work closely with clients to develop tailored testing programs that meet their specific needs and requirements.

Frequently Asked Questions (FAQs)

What types of materials can be tested using this service?

Adhesion strength testing under thermal cycling conditions is suitable for a wide range of materials, including adhesives, coatings, composites, and substrates used in various industries such as automotive, aerospace, construction, and more.

How does the testing process work?

Our team will guide you through the testing process, which typically involves preparing test specimens, subjecting them to thermal cycling conditions, and evaluating adhesion strength using specialized equipment.

What are the advantages of in-house versus outsourced testing?

Outsourcing testing to Eurolab provides several benefits, including access to state-of-the-art equipment, expertise, and the ability to focus on core business activities while ensuring compliance with industry standards.

How long does a typical testing program take?

The duration of a testing program depends on factors such as sample preparation, test parameters, and data analysis. Our team will work closely with you to develop a customized testing plan that meets your needs.

What kind of reports and data analysis can I expect from Eurolab?

We provide comprehensive reports detailing test results, including adhesion strength values, thermal cycling conditions, and recommendations for material improvement or design optimization.

Conclusion

Adhesion strength testing under thermal cycling conditions is a critical aspect of ensuring product reliability, performance, and compliance with industry standards. At Eurolab, we understand the importance of this laboratory service and are committed to helping businesses like yours navigate the complexities of materials science. By partnering with us, you can ensure that your products meet or exceed customer expectations while minimizing warranty claims and associated costs.

Dont wait until its too late contact Eurolab today to discuss how our adhesion strength testing under thermal cycling conditions laboratory service can help take your business to the next level!