Adhesion testing under UV exposure

The Crucial Role of Adhesion Testing under UV Exposure Ensuring the Longevity and Performance of Your Products

In todays fast-paced business environment, companies are constantly seeking innovative ways to improve the quality and performance of their products. One critical aspect that often goes overlooked is the adhesion properties of materials, particularly when exposed to harsh environmental conditions such as ultraviolet (UV) light. Adhesion testing under UV exposure is a laboratory service provided by Eurolab, and it plays a vital role in ensuring the durability and effectiveness of your products.

What is Adhesion Testing under UV Exposure?

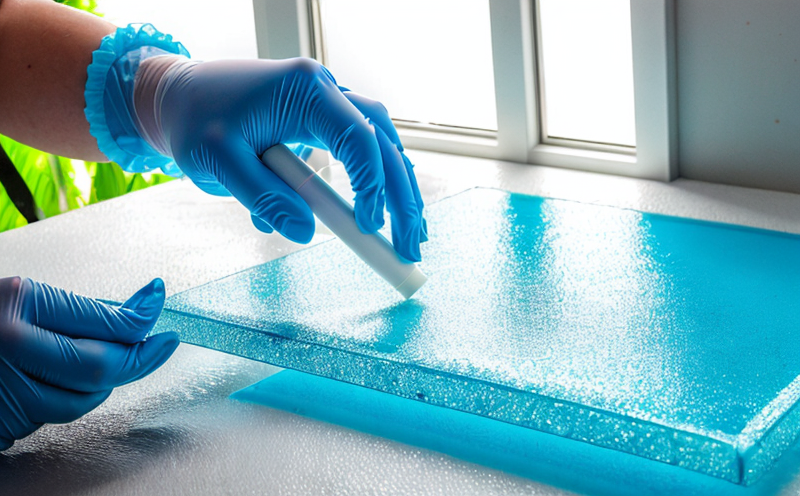

Adhesion testing under UV exposure involves evaluating the bonding strength between two materials or coatings when exposed to ultraviolet light. This type of testing simulates real-world conditions where products are often exposed to sunlight, which can cause adhesives to degrade and fail over time. By conducting adhesion tests under UV exposure, manufacturers can identify potential weaknesses in their products and make necessary adjustments to prevent costly failures.

Why is Adhesion Testing under UV Exposure Essential for Businesses?

In todays competitive market, businesses are constantly looking for ways to differentiate themselves from the competition. Conducting adhesion testing under UV exposure not only ensures product quality but also provides a unique selling point in the marketplace. Here are some key benefits of using this laboratory service

Key Benefits

Improved Product Reliability Adhesion testing under UV exposure helps identify potential weaknesses in products, allowing manufacturers to make necessary adjustments and prevent costly failures.

Enhanced Durability By simulating real-world conditions, manufacturers can ensure their products will withstand the rigors of everyday use and environmental exposure.

Increased Customer Satisfaction Products that meet adhesion standards under UV exposure are more likely to perform as expected, leading to higher customer satisfaction rates and reduced returns.

Compliance with Industry Standards Conducting adhesion testing under UV exposure helps manufacturers comply with industry standards and regulations, reducing the risk of recalls and reputational damage.

Competitive Advantage Businesses that prioritize product quality through adhesion testing under UV exposure can differentiate themselves from competitors and establish a reputation for excellence.

Advantages of Using Eurolabs Adhesion Testing under UV Exposure Service

At Eurolab, we understand the importance of accurate and reliable results. Our state-of-the-art laboratory equipment and experienced team ensure that your samples are tested with precision and care. Here are some advantages of choosing our adhesion testing under UV exposure service

Fast Turnaround Times We strive to provide fast turnaround times without compromising on quality, ensuring you can make informed decisions quickly.

Accurate Results Our expert technicians use advanced equipment to conduct thorough tests, providing accurate results that meet or exceed industry standards.

Wide Range of Materials Tested Eurolabs laboratory is equipped to test a wide range of materials, including plastics, coatings, adhesives, and more.

QA Adhesion Testing under UV Exposure

Q What types of products can be tested for adhesion under UV exposure?

A Our laboratory specializes in testing various materials, including plastics, coatings, adhesives, and other substrates commonly used in industrial applications.

Q How long does the testing process typically take?

A Turnaround times vary depending on the complexity of the test, but most tests can be completed within 1-5 business days.

Q What types of UV exposure conditions are simulated during testing?

A Our laboratory simulates various UV exposure conditions, including accelerated weathering and high-intensity UV light exposure.

Q Can you provide custom testing services to meet specific industry requirements?

A Yes, our team works closely with clients to develop customized testing protocols that meet their unique needs and industry standards.

Conclusion

In todays demanding business environment, companies must prioritize product quality and performance. Adhesion testing under UV exposure is a critical laboratory service provided by Eurolab, ensuring the longevity and effectiveness of your products. By choosing our service, you can improve product reliability, enhance durability, increase customer satisfaction, comply with industry standards, and establish a competitive advantage in the marketplace.

Dont compromise on quality; trust Eurolab to provide accurate and reliable adhesion testing under UV exposure results. Contact us today to learn more about our laboratory services and how we can help you take your products to the next level.