Adhesion strength of coatings on various substrates

The Crucial Importance of Adhesion Strength Ensuring Coatings Stick on Various Substrates

In the world of materials science and coatings technology, adhesion strength is a critical parameter that determines the success or failure of a coating on various substrates. Its the unseen force that holds the coating in place, resisting separation and delamination under different environmental conditions. For businesses across industries, ensuring strong adhesion between coatings and substrates is essential for maintaining product performance, durability, and safety.

As manufacturers strive to develop innovative products with improved functionality, they often overlook the significance of adhesion strength. However, a weak bond can lead to catastrophic consequences, including reduced product lifespan, increased maintenance costs, and even safety risks. This is where Eurolab comes in as a trusted partner for businesses seeking expert analysis and testing services.

In this article, well delve into the world of adhesion strength, exploring its importance, advantages, and the benefits of partnering with Eurolab for laboratory services.

What is Adhesion Strength?

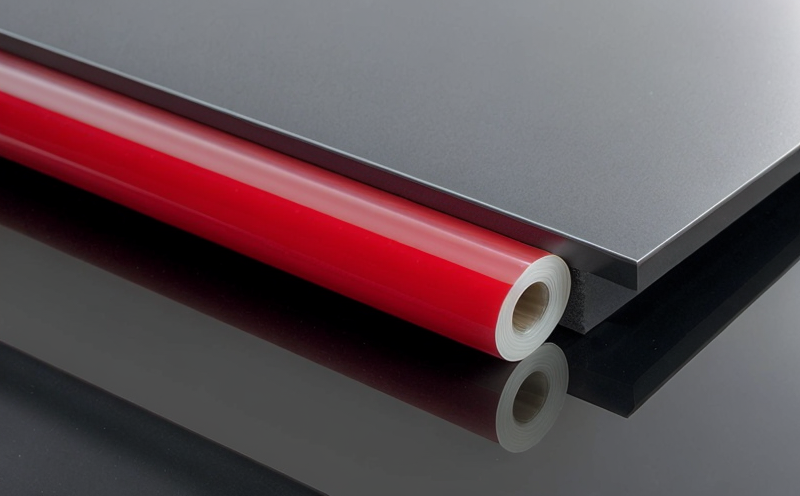

Adhesion strength refers to the ability of a coating to bond with a substrate, resisting separation or delamination under various environmental conditions. Its a complex phenomenon influenced by factors such as surface energy, chemical bonding, mechanical interlocking, and electrostatic attraction.

In essence, adhesion strength is a measure of how well the coating adheres to the substrate, ensuring a durable and long-lasting bond. This property is critical in various industries, including aerospace, automotive, construction, and consumer goods, where coatings are used for corrosion protection, wear resistance, or aesthetic purposes.

Why Adhesion Strength Matters

The significance of adhesion strength cannot be overstated. Here are some compelling reasons why businesses should prioritize this parameter

Product Performance Strong adhesion ensures that coatings maintain their intended properties, such as corrosion resistance, wear resistance, or thermal protection.

Durability and Lifespan A weak bond can lead to premature coating failure, reducing product lifespan and increasing maintenance costs.

Safety Risks Inadequate adhesion can result in catastrophic failures, compromising the safety of users and products.

Cost Savings By ensuring strong adhesion, businesses can reduce waste, minimize rework, and avoid costly repairs or replacements.

Compliance and Regulatory Requirements Adherence to industry standards and regulations often depends on demonstrating robust adhesion strength.

Benefits of Adhesion Strength Testing

At Eurolab, our laboratory services help businesses overcome the challenges associated with adhesion strength. Here are some key benefits of partnering with us

Accurate Results Our state-of-the-art facilities and experienced analysts provide precise measurements of adhesion strength.

Comprehensive Analysis We offer a range of testing methods to evaluate adhesion under various conditions, including temperature, humidity, and mechanical stress.

Improved Product Development By understanding the relationship between coating formulation, substrate properties, and adhesion strength, businesses can optimize their products for enhanced performance and durability.

Reduced Risks Our expert analysis helps identify potential issues before they become critical problems, minimizing risks associated with product failure or regulatory non-compliance.

Eurolabs Adhesion Strength Laboratory Services

Our team of experts provides a range of laboratory services to evaluate adhesion strength on various substrates

Pull-off Testing Measures the force required to separate the coating from the substrate.

Cross-cut Adhesion Testing Evaluates adhesion by applying a series of cuts to the coated surface and measuring the resulting bond strength.

Wedge Test Assesses adhesion under compressive stress, simulating real-world conditions.

Frequently Asked Questions (FAQs)

Q What types of substrates can be tested for adhesion strength?

A We test a wide range of substrates, including metals, ceramics, plastics, and composites.

Q How do I choose the right testing method for my application?

A Our experts will work with you to select the most suitable testing methodology based on your specific requirements and industry standards.

Q What are the common causes of poor adhesion strength?

A Inadequate surface preparation, incompatible coating-substrate combinations, or environmental factors can contribute to weak adhesion.

Q Can Eurolab provide customized testing protocols for my product?

A Yes, our team will work with you to develop tailored testing procedures that meet your specific needs and industry requirements.

Conclusion

Adhesion strength is a critical parameter in coatings technology, and its importance cannot be overstated. By partnering with Eurolab, businesses can ensure strong adhesion between coatings and substrates, reducing risks associated with product failure or regulatory non-compliance. Our laboratory services provide accurate results, comprehensive analysis, and improved product development, helping you make informed decisions about your products.

Dont compromise on the performance and safety of your products choose Eurolab for expert analysis and testing services. Contact us today to learn more about our adhesion strength laboratory services and take the first step towards ensuring strong bonds between coatings and substrates.