Assessing the impact of surface treatment on medical device performance

Assessing the Impact of Surface Treatment on Medical Device Performance Unlocking Reliability and Safety

In the realm of medical devices, surface treatment plays a vital role in determining the overall performance and efficacy of these critical tools. A precise understanding of how surface treatments affect medical device functionality is essential for manufacturers seeking to ensure reliability, safety, and compliance with regulatory standards. This is where Assessing the Impact of Surface Treatment on Medical Device Performance comes into play a laboratory service provided by Eurolab that helps businesses navigate the complex world of surface treatment analysis.

What is Assessing the Impact of Surface Treatment on Medical Device Performance?

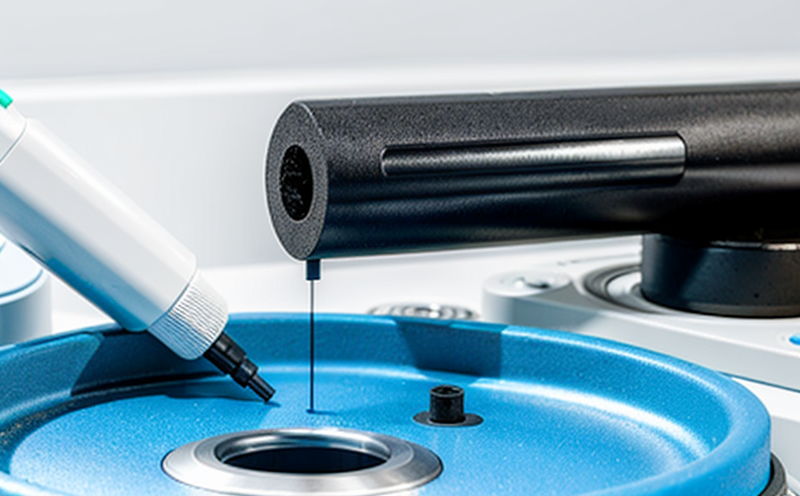

In essence, this laboratory service entails an in-depth examination of how various surface treatments influence the performance characteristics of medical devices. By subjecting these devices to a range of rigorous tests and analyses, Eurolabs experts can provide actionable insights into their chemical, mechanical, and biological properties. This comprehensive evaluation is crucial for companies that wish to optimize device functionality, minimize risks associated with device failure, and ensure seamless integration with other system components.

Why is Assessing the Impact of Surface Treatment on Medical Device Performance Essential?

Investing in surface treatment analysis can have far-reaching benefits for businesses, including

Improved Reliability By understanding how surface treatments impact medical device performance, manufacturers can identify areas for improvement, reducing the likelihood of device failure and subsequent patient harm.

Enhanced Safety Comprehensive analysis of surface-treated devices allows for identification of potential risks associated with material degradation, corrosion, or other factors that may compromise device safety.

Regulatory Compliance Demonstrating adherence to regulatory standards is crucial for medical device manufacturers. Eurolabs laboratory service helps companies ensure compliance with relevant regulations by providing detailed data on device performance characteristics.

Increased Efficiency By identifying optimal surface treatment strategies, businesses can streamline production processes, reduce material waste, and optimize resource allocation.

Key Benefits of Assessing the Impact of Surface Treatment on Medical Device Performance

Data-Driven Decision-Making Eurolabs laboratory service provides manufacturers with actionable data to inform surface treatment decisions, ensuring that devices are designed and constructed with optimal performance characteristics.

Minimized Material Waste By identifying areas for improvement in device design or manufacturing processes, companies can reduce material waste and associated costs.

Improved Device Efficacy Comprehensive analysis of surface-treated devices enables manufacturers to fine-tune their products functionality, ensuring they meet the highest standards of performance and efficacy.

Reduced Risk of Device Failure Identifying potential risks associated with device failure allows manufacturers to take proactive steps to mitigate these risks, reducing the likelihood of costly recalls or product liability claims.

How Can Eurolabs Assessing the Impact of Surface Treatment on Medical Device Performance Benefit Your Business?

Our laboratory service offers a unique combination of technical expertise and state-of-the-art facilities. By partnering with Eurolab, your business can

Benefit from Expertise Our team of experienced analysts and scientists possess in-depth knowledge of surface treatment analysis and its applications in medical device manufacturing.

Access Advanced Facilities Eurolabs laboratory is equipped with cutting-edge equipment and technologies, ensuring that our testing and analysis processes are as precise and efficient as possible.

Ensure Compliance We help manufacturers navigate complex regulatory landscapes, ensuring adherence to relevant standards and regulations.

Frequently Asked Questions (FAQs)

Q What types of surface treatments can be analyzed through Eurolabs laboratory service?

A Our experts can analyze a wide range of surface treatments, including but not limited to electroplating, anodizing, passivation, blasting, and coating.

Q How long does the analysis process typically take?

A The duration of our laboratory service varies depending on the specific requirements of your project. However, most analyses can be completed within 2-4 weeks.

Q What types of medical devices can be assessed through Eurolabs laboratory service?

A Our experts can analyze a broad range of medical devices, including but not limited to implants, surgical instruments, diagnostic equipment, and prosthetics.

Q Can I trust the accuracy and reliability of data generated by Eurolabs laboratory service?

A Absolutely. We adhere to strict quality control measures and employ rigorous testing protocols to ensure that our data is accurate, reliable, and actionable for your business needs.

Conclusion

Assessing the impact of surface treatment on medical device performance is a critical aspect of ensuring the reliability, safety, and efficacy of these essential tools. By partnering with Eurolabs laboratory service, businesses can unlock valuable insights into their products chemical, mechanical, and biological properties, enabling informed decision-making and streamlined production processes. Dont compromise your business invest in surface treatment analysis today and take the first step towards improved reliability, safety, and regulatory compliance.