Testing the hydrophobicity or hydrophilicity of medical device surfaces

Testing the Hydrophobicity or Hydrophilicity of Medical Device Surfaces Unlocking the Secrets to Preventing Contamination and Ensuring Patient Safety

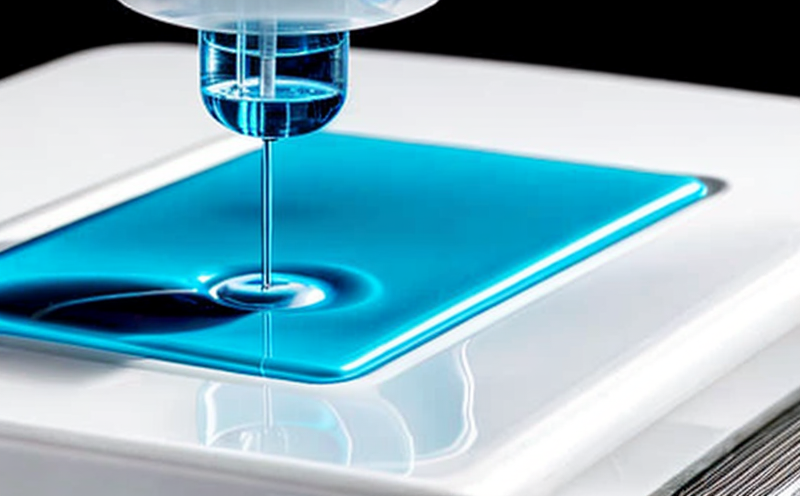

In the medical device industry, ensuring the safety and efficacy of products is paramount. One crucial aspect of this endeavor is understanding the hydrophobicity (water-repelling) or hydrophilicity (water-attracting) properties of surfaces. Medical devices that come into contact with bodily fluids must be carefully designed to prevent contamination, infection, and other complications. Testing the hydrophobicity or hydrophilicity of medical device surfaces has become an essential service for businesses seeking to guarantee the quality and performance of their products.

At Eurolab, our team of experts offers a comprehensive laboratory service dedicated to testing the hydrophobicity or hydrophilicity of medical device surfaces. By partnering with us, you can rest assured that your devices meet the highest standards of safety and effectiveness, ultimately protecting patients and enhancing your brands reputation.

The Importance of Hydrophobicity/Hydrophilicity Testing

Hydrophobicity/hydrophilicity testing is crucial for several reasons

Preventing contamination Medical devices must be able to withstand exposure to bodily fluids without compromising their integrity or allowing the spread of microorganisms. Our testing services help ensure that your products meet these requirements.

Ensuring patient safety By verifying the hydrophobicity/hydrophilicity properties of your device surfaces, we can prevent adverse reactions and infections in patients, safeguarding their well-being and trust in medical technology.

Compliance with regulations Regulatory agencies demand strict adherence to guidelines for medical device testing. Our services will help you meet these standards, reducing the risk of costly recalls or non-compliance penalties.

Advantages of Hydrophobicity/Hydrophilicity Testing

Here are some key benefits of partnering with Eurolab

Benefits for Medical Device Manufacturers

Enhanced product quality By testing your device surfaces, we can identify potential issues and optimize their design to prevent contamination and ensure patient safety.

Reduced recall risk Our testing services help you avoid costly recalls by identifying and addressing potential problems before they reach the market.

Improved regulatory compliance Well work with you to ensure that your products meet all relevant regulations, reducing the likelihood of non-compliance penalties.

Benefits for Hospitals and Healthcare Providers

Reduced infection rates By selecting devices that have been thoroughly tested for hydrophobicity/hydrophilicity properties, hospitals can lower the risk of infections and improve patient outcomes.

Enhanced patient trust When medical devices are designed with safety in mind, patients feel more confident in their care, leading to improved satisfaction and loyalty.

Cost savings By reducing the likelihood of contamination and infection, hospitals can save on healthcare costs associated with treating these complications.

Benefits for Regulatory Agencies

Improved product safety Our testing services support regulatory agencies by ensuring that medical devices meet strict guidelines for hydrophobicity/hydrophilicity properties.

Reduced enforcement efforts By partnering with Eurolab, regulatory agencies can rely on our expertise to verify compliance and minimize the need for enforcement actions.

Benefits for Research Institutions

Advancements in medical technology Our testing services contribute to research and development by helping scientists and engineers optimize device design and materials.

Collaborative opportunities We welcome partnerships with research institutions, fostering a shared commitment to advancing medical technology.

Frequently Asked Questions

Q What is the process for testing hydrophobicity/hydrophilicity properties?

A Our team will work closely with you to determine the best approach for your specific device. This may involve surface analysis techniques such as contact angle measurement or X-ray photoelectron spectroscopy (XPS).

Q How long does the testing process take?

A The duration of our services varies depending on the complexity of the project, but we typically deliver results within 2-6 weeks.

Q What types of medical devices can be tested for hydrophobicity/hydrophilicity properties?

A We offer testing services for a wide range of medical devices, including implants, surgical instruments, and diagnostic equipment.

Q Are your testing services ISO/IEC 17025 accredited?

A Yes, our laboratory is certified to the international standard for calibration and testing laboratories (ISO/IEC 17025), ensuring the highest level of quality and reliability.

Conclusion

At Eurolab, we understand the critical importance of testing hydrophobicity/hydrophilicity properties in medical device surfaces. By partnering with us, businesses can ensure that their products meet the strictest standards for safety and performance. Our comprehensive laboratory service is dedicated to supporting manufacturers, hospitals, healthcare providers, regulatory agencies, and research institutions in their pursuit of excellence.

With our expertise and state-of-the-art facilities, you can trust that your medical devices will be thoroughly tested to prevent contamination and ensure patient safety. Join the ranks of companies that have already benefited from our services and experience the Eurolab difference for yourself.

Get Started Today

Contact us to learn more about our hydrophobicity/hydrophilicity testing services and how we can help you achieve your goals. Together, lets unlock the secrets to preventing contamination and ensuring patient safety through advanced medical device testing.