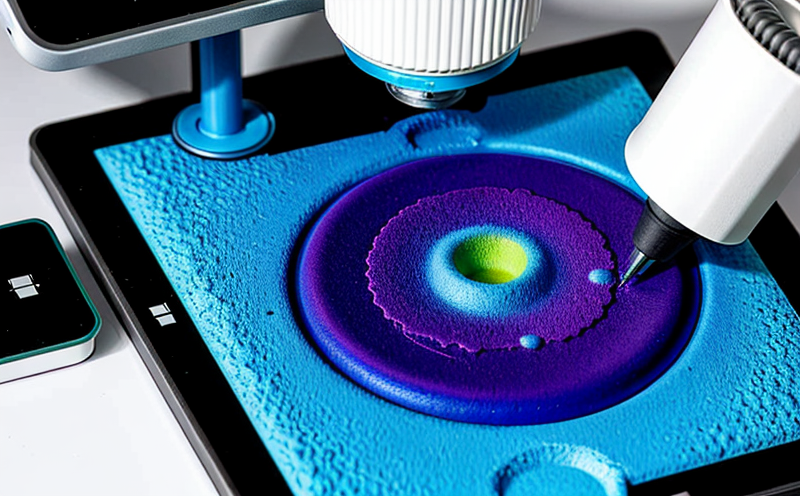

Testing the surface topography of medical devices using microscopy

Unlock the Secrets of Medical Device Surface Topography with Eurolabs Advanced Microscopy Services

In the rapidly evolving landscape of medical device manufacturing, the demands for precision and reliability are at an all-time high. With increasingly complex devices being developed to meet the needs of patients worldwide, its crucial for manufacturers to ensure their products surface topography meets stringent quality control standards. Thats where Eurolab comes in a trusted leader in laboratory services providing cutting-edge microscopy solutions to test the surface topography of medical devices.

What is Testing the Surface Topography of Medical Devices using Microscopy?

Surface topography refers to the intricate details and irregularities on a devices surface, which can significantly impact its functionality, safety, and overall performance. The surface topography of medical devices, in particular, must be meticulously examined to guarantee their efficacy, minimize the risk of complications, and ensure compliance with regulatory requirements.

Our microscopy services utilize state-of-the-art equipment and expert techniques to inspect the surface morphology of various medical device components, including implantable devices, surgical instruments, and diagnostic equipment. By leveraging Eurolabs advanced microscopy capabilities, manufacturers can gain invaluable insights into their products surface characteristics, enabling them to optimize design, improve quality, and enhance patient outcomes.

Why is Testing the Surface Topography of Medical Devices using Microscopy Essential?

The advantages of utilizing microscopy services to assess medical device surface topography are multifaceted and far-reaching. Here are some key benefits

Advantages of Eurolabs Microscopy Services

Enhanced Product Reliability By identifying potential issues with surface topography, manufacturers can minimize the risk of device failure, reducing costly recalls and improving overall product reliability.

Improved Patient Safety Accurate inspection of medical device surfaces ensures that patients are protected from potential complications associated with flawed or defective products.

Compliance with Regulatory Requirements Our microscopy services help manufacturers meet stringent regulatory standards, such as those set by the FDA (US) and CE Marking (EU), ensuring seamless market access and minimizing the risk of costly compliance issues.

Cost Savings By detecting defects early in the manufacturing process, companies can avoid costly rework, reducing waste and minimizing financial losses.

Increased Efficiency Our microscopy services enable manufacturers to optimize production processes, streamline quality control procedures, and reduce testing times, leading to improved productivity and competitiveness.

Key Benefits of Eurolabs Microscopy Services

Non-Destructive Testing (NDT) Our advanced microscopy techniques allow for non-destructive inspection of medical devices, preserving the integrity of the product and eliminating the need for destructive testing methods.

High-Resolution Imaging Eurolabs state-of-the-art equipment provides exceptional resolution and detail, enabling precise analysis of even the smallest surface features.

Expert Analysis Our team of experienced microscopists and engineers provide in-depth interpretation of results, offering valuable insights and recommendations to manufacturers.

Frequently Asked Questions (FAQs)

Q What types of medical devices can be inspected using Eurolabs microscopy services?

A We offer inspection services for a wide range of medical device components, including implantable devices, surgical instruments, diagnostic equipment, and more.

Q What is the typical turnaround time for microscopy services at Eurolab?

A Our dedicated team strives to deliver results within an expedited timeframe, often as quickly as 24-48 hours, depending on the scope of work.

Q How do I ensure compliance with regulatory requirements through Eurolabs microscopy services?

A Our experienced staff will guide you through the inspection process and provide detailed reports that meet or exceed regulatory standards, ensuring seamless market access.

Q Can Eurolabs microscopy services be integrated into our existing quality control processes?

A Absolutely! We work closely with manufacturers to integrate our microscopy services seamlessly into their existing QA protocols, streamlining their testing procedures.

Conclusion

In the world of medical device manufacturing, surface topography inspection is a critical component of product development and validation. By partnering with Eurolab for advanced microscopy services, manufacturers can ensure their products meet stringent quality control standards, enhance patient safety, and drive business success. Trust our team of experts to unlock the secrets of your medical devices surface topography contact us today to learn more about how Eurolab can help your business thrive.

Learn More About Eurolabs Microscopy Services

Stay ahead in the fast-paced world of medical device manufacturing by leveraging Eurolabs cutting-edge microscopy solutions. Our team is committed to delivering exceptional service, ensuring that your products meet or exceed regulatory requirements, and enhancing patient outcomes through precision surface topography inspection.