Assessing the influence of surface finish on medical device mechanical properties

The Crucial Role of Surface Finish in Medical Device Mechanical Properties Why Assessing its Influence is Essential for Your Business

As the medical device industry continues to evolve and innovate, manufacturers are under increasing pressure to produce high-quality products that meet rigorous standards. One critical aspect of ensuring the integrity of these devices is assessing the influence of surface finish on mechanical properties. In this article, well delve into the importance of this laboratory service, provided by Eurolab, and explore its numerous benefits for businesses.

What is Assessing the Influence of Surface Finish on Medical Device Mechanical Properties?

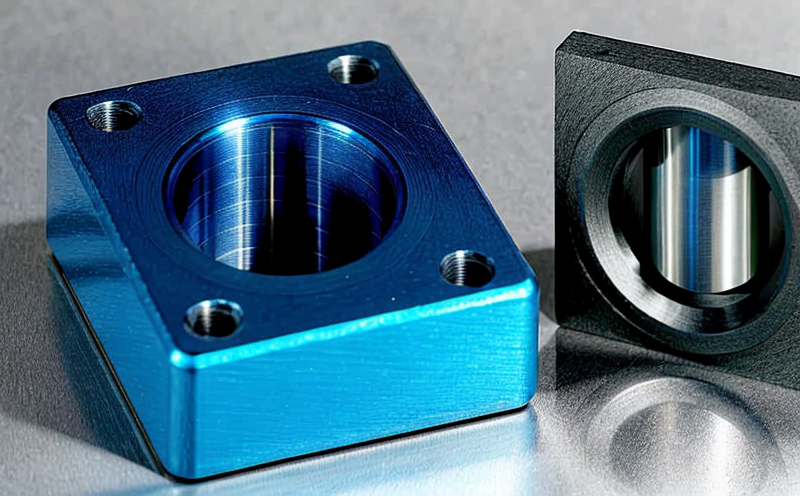

Surface finish refers to the texture and characteristics of a materials surface, which can significantly impact its mechanical properties. In medical devices, a smooth surface finish can improve biocompatibility, reduce wear and tear, and enhance overall performance. Conversely, a rough or uneven surface finish can lead to compromised device functionality, reduced lifespan, and even patient harm.

Eurolabs Assessing the Influence of Surface Finish on Medical Device Mechanical Properties service enables manufacturers to evaluate the impact of surface finish on their products mechanical properties. By conducting rigorous testing and analysis, our team of experts provides actionable insights that inform design improvements, material selection, and process optimization.

Advantages of Using Eurolabs Assessment Service

The benefits of assessing the influence of surface finish on medical device mechanical properties are multifaceted

Improved product reliability By understanding how surface finish affects device performance, manufacturers can mitigate risks associated with faulty or compromised products.

Enhanced biocompatibility Smooth surfaces reduce the risk of adverse reactions and ensure better compatibility with bodily tissues.

Increased lifespan Devices with optimal surface finishes exhibit reduced wear and tear, extending their useful life and reducing maintenance costs.

Reduced recalls and liability Manufacturers can minimize the risk of product recalls by identifying and addressing surface finish-related issues early on.

Cost savings By optimizing material selection and manufacturing processes, businesses can reduce production costs without compromising quality.

Key Benefits

Comprehensive analysis Eurolabs experts conduct thorough testing and evaluation to determine how surface finish impacts mechanical properties.

Customized solutions Our team develops tailored recommendations for design improvements, material selection, and process optimization based on individual client needs.

Industry-recognized standards We adhere to rigorous standards and guidelines set by regulatory bodies, ensuring that our assessments meet or exceed industry requirements.

Scalability Eurolabs assessment service is adaptable to various product sizes and complexities, accommodating the diverse needs of clients.

QA Frequently Asked Questions about Assessing the Influence of Surface Finish on Medical Device Mechanical Properties

Q1 What types of medical devices can benefit from this assessment?

A Our assessment service applies to a wide range of medical devices, including implants, surgical instruments, diagnostic equipment, and more. Any product that requires evaluation of surface finish for mechanical properties is suitable.

Q2 How does Eurolabs team conduct the assessment?

A Our experts employ state-of-the-art testing equipment and methodologies to evaluate the impact of surface finish on mechanical properties. We analyze data from various parameters, including roughness, waviness, and surface topography.

Q3 What are the typical results and outputs of this assessment service?

A Clients receive a comprehensive report detailing our findings, including recommendations for design improvements, material selection, and process optimization. This information enables businesses to make informed decisions about their products and manufacturing processes.

Q4 Can Eurolabs assessment service be integrated with other laboratory services?

A Yes! Our team offers a range of complementary services, including mechanical testing, materials characterization, and contamination control. We can customize packages to suit your specific needs and requirements.

Conclusion

Assessing the influence of surface finish on medical device mechanical properties is an essential step in ensuring the quality and performance of medical devices. Eurolabs laboratory service provides manufacturers with actionable insights that inform design improvements, material selection, and process optimization.

By partnering with Eurolab, businesses can

Enhance product reliability

Improve biocompatibility

Increase lifespan

Reduce recalls and liability

Save costs

Dont compromise on the integrity of your medical devices. Contact Eurolab today to learn more about our Assessing the Influence of Surface Finish on Medical Device Mechanical Properties service.

Learn More About Our Services (link)

Get in Touch with Us (link)