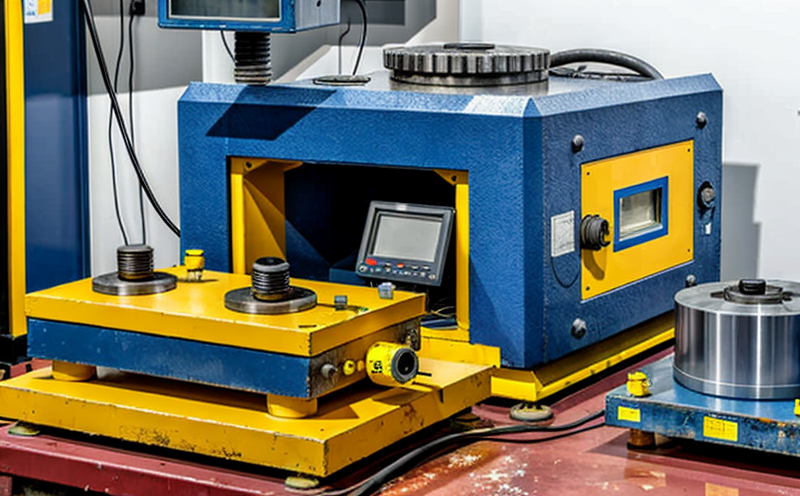

Equipment used in fatigue testing

The Crucial Role of Equipment Used in Fatigue Testing Ensuring the Reliability and Longevity of Your Products

In todays fast-paced business landscape, companies are constantly striving to improve their products performance, efficiency, and lifespan. One critical aspect of achieving this goal is through fatigue testing a laboratory service that simulates real-world conditions to evaluate a products endurance under repeated stress. At Eurolab, our expertise in equipment used for fatigue testing enables businesses like yours to make informed decisions about product design, material selection, and manufacturing processes.

Fatigue testing is an essential tool for manufacturers seeking to reduce costs associated with product failures, recalls, and warranty claims. By understanding how products behave under various loads, companies can optimize their designs to prevent premature wear and tear, ultimately reducing the likelihood of costly downtime and increasing overall customer satisfaction.

The Benefits of Equipment Used in Fatigue Testing

Improved Product Reliability Equipments used for fatigue testing help identify potential weaknesses in product design or material selection, allowing manufacturers to make targeted improvements.

Enhanced Customer Satisfaction By ensuring products can withstand real-world conditions, companies reduce the likelihood of customer complaints and increase overall satisfaction.

Reduced Costs Fatigue testing helps eliminate costly product failures, recalls, and warranty claims, saving businesses millions in potential losses.

Increased Product Lifespan Equipments used for fatigue testing enable manufacturers to design products that last longer, reducing the need for frequent replacements and minimizing waste.

Key Benefits of Equipment Used in Fatigue Testing

Accurate Predictive Modeling Our equipment allows for precise simulation of real-world conditions, providing accurate predictive modeling and reduced risk of product failure.

Real-Time Monitoring Advanced sensors and monitoring systems enable real-time tracking of product performance, allowing for swift identification of potential issues.

Customizable Testing Parameters Equipments used for fatigue testing can be tailored to meet specific industry or application requirements, ensuring relevant results and actionable insights.

Compliance with Industry Standards Our equipment ensures compliance with relevant industry standards and regulations, reducing the risk of non-compliance and associated penalties.

QA Frequently Asked Questions about Equipment Used in Fatigue Testing

What is fatigue testing?

Fatigue testing is a laboratory service that simulates real-world conditions to evaluate a products endurance under repeated stress.

Why is fatigue testing essential for my business?

Fatigue testing helps identify potential weaknesses in product design or material selection, ensuring products can withstand real-world conditions and reducing the likelihood of costly downtime.

How does Eurolab ensure accurate results?

Our expert team uses state-of-the-art equipment and follows strict quality control procedures to guarantee precise and reliable results.

Can I customize testing parameters for my specific industry or application?

Yes, our equipment can be tailored to meet your unique needs and requirements, ensuring relevant results and actionable insights.

Do you offer any certification or compliance services?

Yes, we provide certification and compliance services to ensure that your products meet relevant industry standards and regulations.

The Eurolab Advantage

At Eurolab, our commitment to innovation, quality, and customer satisfaction sets us apart from other laboratory service providers. With a team of experienced experts and state-of-the-art equipment, we offer

Comprehensive Testing Services Our equipment is designed to simulate real-world conditions, providing comprehensive testing services for a wide range of industries.

Customized Solutions We work closely with clients to develop tailored testing programs that meet their specific needs and requirements.

Certification and Compliance Services Our team ensures that your products meet relevant industry standards and regulations, reducing the risk of non-compliance.

In conclusion, equipment used in fatigue testing is a critical tool for businesses seeking to improve product reliability, customer satisfaction, and overall performance. By partnering with Eurolab, you can trust that our expertise and state-of-the-art equipment will provide accurate and actionable insights, enabling informed decisions about product design, material selection, and manufacturing processes.