Importance of cyclic loading in fatigue testing

The Crucial Role of Cyclic Loading in Fatigue Testing Unlocking Material Reliability and Safety

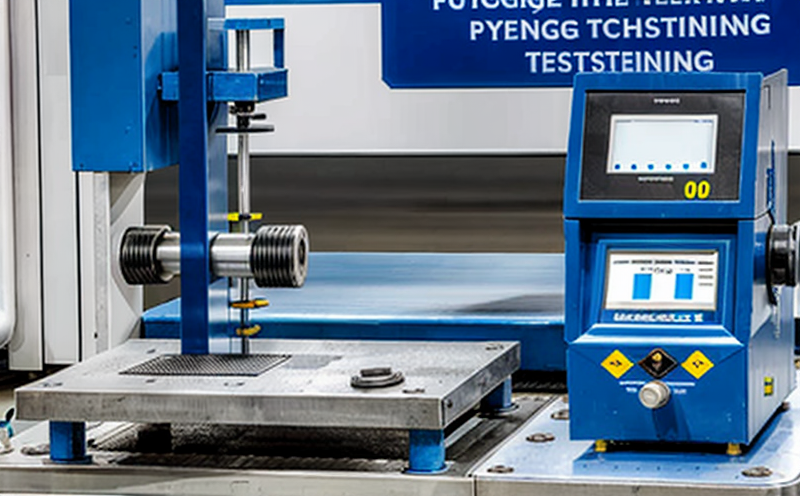

In the world of materials science and engineering, fatigue testing is a critical process that helps determine the lifespan and reliability of various products and structures subjected to cyclic loading. Cyclic loading, which involves repeated loading and unloading cycles, can cause materials to fail prematurely due to fatigue cracking or plastic deformation. As manufacturers strive to create safer, more efficient, and durable products, its essential to understand the significance of cyclic loading in fatigue testing.

At Eurolab, our laboratory service specializes in providing comprehensive fatigue testing solutions, including cyclic loading tests, to help businesses ensure material reliability and safety. In this article, well delve into the importance of cyclic loading in fatigue testing, highlighting its advantages, key benefits, and applications across various industries.

What is Cyclic Loading in Fatigue Testing?

Cyclic loading refers to the repeated application and removal of forces or stresses on a material or structure, causing it to cycle through different stages of tension and compression. This process can lead to material fatigue, where small cracks initiate and propagate under cyclic loading, ultimately resulting in failure.

Fatigue testing with cyclic loading is an essential tool for engineers and researchers to

Evaluate the durability and reliability of materials

Identify potential failure modes and mechanisms

Develop predictive models for material lifespan

Optimize design and manufacturing processes

Advantages of Using Cyclic Loading in Fatigue Testing

Eurolabs cyclic loading fatigue testing service offers numerous benefits, including

Accurate Material Characterization Cyclic loading tests provide a comprehensive understanding of material behavior under repeated loading conditions, enabling engineers to accurately predict material lifespan and reliability.

Improved Product Design and Manufacturing By simulating real-world load cycles, our testing services help manufacturers identify potential design flaws and optimize product configurations for improved performance and durability.

Enhanced Safety and Reliability Cyclic loading fatigue testing reduces the risk of premature failure, ensuring that products meet or exceed regulatory standards and customer expectations.

Cost Savings Our expert team can help you avoid costly redesigns, retooling, and production delays by identifying material limitations and potential failure modes early in the development process.

Increased Efficiency and Productivity With our cyclic loading fatigue testing services, businesses can accelerate product development, reduce time-to-market, and stay competitive in their respective industries.

Key Benefits of Cyclic Loading Fatigue Testing

Here are some key benefits of using cyclic loading in fatigue testing

Predictive Modeling Our cyclic loading tests provide valuable data for developing predictive models that estimate material lifespan under various loading conditions.

Material Selection We help you choose the most suitable materials for your application, considering factors like strength, toughness, and resistance to fatigue.

Design Optimization By simulating real-world load cycles, our testing services enable engineers to optimize product designs for improved performance, reduced weight, and increased durability.

Quality Control Cyclic loading fatigue testing ensures that products meet or exceed quality standards, reducing the risk of premature failure and warranty claims.

QA Section Frequently Asked Questions about Cyclic Loading in Fatigue Testing

Q1 What is the primary purpose of cyclic loading in fatigue testing?

A1 The primary goal of cyclic loading in fatigue testing is to simulate real-world load cycles and evaluate material behavior under repeated loading conditions, enabling engineers to predict material lifespan and reliability.

Q2 How does Eurolabs cyclic loading fatigue testing service differ from other laboratory services?

A2 Our expert team uses state-of-the-art equipment and customized testing protocols to provide accurate and reliable results. We also offer a range of testing frequencies, load amplitudes, and sample sizes to meet specific client requirements.

Q3 Can cyclic loading fatigue testing be applied to various industries?

A3 Yes! Cyclic loading fatigue testing is applicable across multiple industries, including aerospace, automotive, energy, construction, and medical devices. Our expert team works closely with clients to understand their specific needs and tailor our services accordingly.

Conclusion

In conclusion, cyclic loading in fatigue testing plays a vital role in ensuring material reliability and safety across various industries. By using Eurolabs laboratory service, businesses can

Accurately characterize material behavior under cyclic loading conditions

Identify potential failure modes and mechanisms

Develop predictive models for material lifespan

Optimize design and manufacturing processes

Dont compromise on product quality and safety choose Eurolabs cyclic loading fatigue testing service to unlock the full potential of your materials and ensure compliance with regulatory standards.

About Eurolab

At Eurolab, our expert team is dedicated to providing comprehensive laboratory services that meet or exceed client expectations. With a focus on cyclic loading fatigue testing, we help businesses ensure material reliability and safety across various industries. Contact us today to learn more about our services and how we can support your product development needs!