Long-term effects of fatigue testing on material properties

The Hidden Consequences of Fatigue Testing Unveiling the Long-term Effects on Material Properties

As a business leader, you understand the importance of ensuring that your products meet the highest standards of quality and reliability. One crucial aspect of achieving this goal is through the process of fatigue testing, which simulates real-world conditions to predict how materials will perform over time. However, what happens after the initial test? Do the results hold up in the long term? This is where our expert laboratory service comes in Eurolabs Long-term effects of fatigue testing on material properties.

In this article, well delve into the world of fatigue testing and explore its long-term consequences on material properties. Well discuss why this specialized service is essential for businesses looking to optimize their products performance and lifespan.

Why Long-term Effects of Fatigue Testing Matter

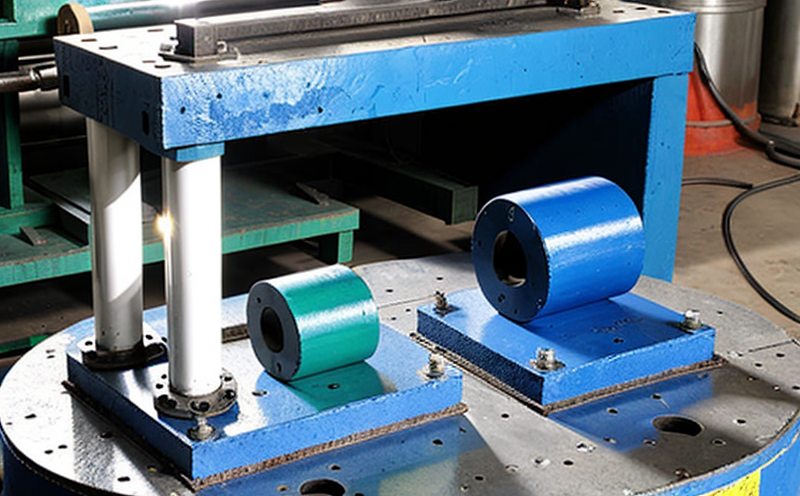

Fatigue testing is a widely recognized method used to evaluate the durability of materials under repeated stress or loading conditions. By simulating real-world scenarios, manufacturers can gain valuable insights into how their products will behave over time. However, the initial fatigue test only provides a snapshot of a materials performance at that specific moment. What about the long-term effects?

The truth is, many factors can influence a materials behavior after the initial test. Temperature fluctuations, exposure to environmental stressors, and changes in loading conditions can all impact its properties over time. These subtle variations can lead to unexpected failures or decreased product lifespan.

Advantages of Long-term Effects of Fatigue Testing on Material Properties

Our laboratory service, offered by Eurolab, provides businesses with a comprehensive understanding of their materials long-term performance. Here are the key benefits

Improved Product Reliability By simulating real-world conditions over an extended period, our experts can identify potential issues before they become major problems.

Increased Product Lifespan Armed with data on material degradation, manufacturers can optimize product design and maintenance schedules to extend their products lifespan.

Reduced Warranty Claims With a deeper understanding of material behavior, businesses can develop more accurate warranty claims and reduce associated costs.

Enhanced Consumer Confidence By demonstrating commitment to quality and reliability, companies can build trust with customers and establish themselves as industry leaders.

Long-term Effects of Fatigue Testing A Breakdown

Here are the key aspects to consider when evaluating the long-term effects of fatigue testing

Material Degradation Fatigue testing reveals how materials break down over time due to repeated stress or loading conditions. Our experts analyze this degradation to provide insights into potential lifespan and product performance.

Stress Corrosion Cracking (SCC) This phenomenon occurs when a material is subjected to both tensile stress and corrosive environments, leading to premature failure. Eurolabs long-term fatigue testing helps identify SCC risks and mitigate them through design improvements or coatings.

Fatigue Crack Growth Fatigue testing exposes the rate at which cracks propagate through materials under cyclic loading conditions. Our analysis provides data on crack growth rates, enabling manufacturers to predict product lifespan and optimize maintenance schedules.

QA Long-term Effects of Fatigue Testing on Material Properties

We understand you might have questions about our laboratory service. Here are some answers to common queries

What materials can be tested?

Our long-term fatigue testing services cover a wide range of materials, including metals, polymers, ceramics, and composites.

How do I know which test conditions to apply?

Eurolabs experts will work with you to select the most relevant test conditions based on your specific application and material properties.

Can fatigue testing be performed at elevated temperatures?

Yes, our laboratory facilities allow for temperature-controlled testing, enabling simulation of real-world operating conditions.

By partnering with Eurolab, businesses can ensure their products meet the highest standards of quality and reliability. Dont let the long-term effects of fatigue testing catch you off guard schedule a test today to uncover hidden consequences and optimize your products performance.

At Eurolab, our mission is to empower manufacturers with the knowledge they need to create exceptional products that exceed customer expectations. Our laboratory service provides unparalleled insights into material behavior under various conditions, enabling businesses to

Reduce warranty claims

Increase product lifespan

Enhance consumer confidence

Establish a reputation for quality and reliability

Dont wait until its too late take the first step towards optimizing your products performance and lifespan with Eurolabs Long-term effects of fatigue testing on material properties.