Impact of fatigue testing on material selection

The Crucial Role of Fatigue Testing in Material Selection Why Businesses Cant Afford to Ignore It

In todays fast-paced and highly competitive business landscape, companies are constantly seeking ways to improve the performance, durability, and efficiency of their products. One crucial aspect that is often overlooked but plays a pivotal role in achieving these goals is material selection. Choosing the right materials for your products can make all the difference between success and failure. However, with an overwhelming array of options available, selecting the most suitable materials can be a daunting task.

Thats where fatigue testing comes into play. By understanding how different materials behave under repeated stress and strain, businesses can ensure that their products withstand the rigors of real-world usage. In this article, we will delve into the impact of fatigue testing on material selection and explore why it is an essential laboratory service for companies looking to stay ahead of the curve.

What is Fatigue Testing?

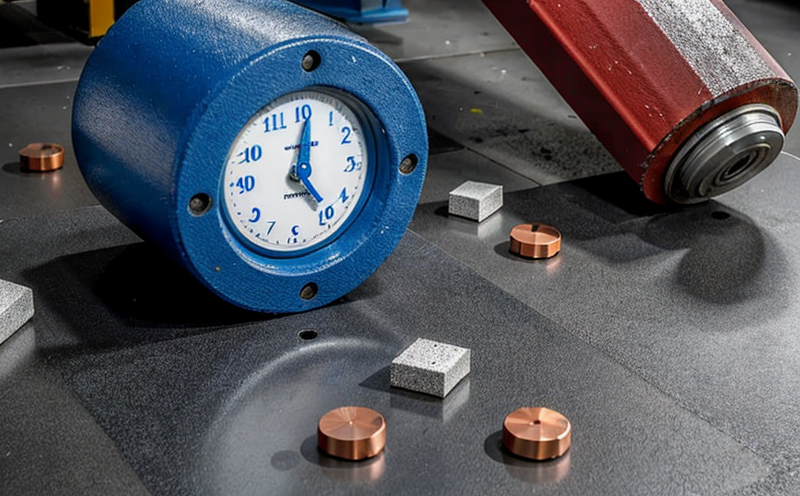

Fatigue testing involves subjecting materials or components to repeated cycles of stress and strain until failure occurs. This process allows researchers to understand how different materials respond to various loading conditions, including cyclic loading, dynamic loading, and impact loading. By analyzing the results of fatigue tests, businesses can make informed decisions about which materials are best suited for their products.

Why is Fatigue Testing Crucial for Material Selection?

Fatigue testing plays a vital role in material selection because it provides valuable insights into the behavior of different materials under various loading conditions. By understanding how materials respond to repeated stress and strain, businesses can

Reduce the risk of product failure Fatigue testing helps identify which materials are more prone to cracking or breaking due to repeated stress and strain.

Improve material durability By selecting materials that have proven to withstand repeated loading cycles, businesses can ensure their products remain durable over time.

Enhance product performance Fatigue testing enables researchers to optimize material selection based on specific application requirements, ensuring that products meet the necessary standards for safety and functionality.

Minimize maintenance costs By selecting materials with a longer lifespan, businesses can reduce the need for frequent repairs or replacements, resulting in significant cost savings.

Key Benefits of Using Impact of Fatigue Testing on Material Selection

Here are some key benefits of incorporating fatigue testing into your material selection process

Improved product reliability By understanding how different materials behave under repeated stress and strain, businesses can select materials that ensure their products perform reliably over time.

Reduced warranty claims Companies can minimize the risk of product failure and subsequent warranty claims by selecting materials with a proven track record of durability.

Increased customer satisfaction Fatigue testing enables businesses to develop products that meet or exceed customer expectations, resulting in higher levels of satisfaction and loyalty.

Competitive advantage By leveraging fatigue testing to select the most suitable materials for their products, companies can differentiate themselves from competitors and establish a reputation for quality and reliability.

Frequently Asked Questions (FAQs)

Here are some common questions about fatigue testing and material selection

Q What types of materials can be tested using fatigue testing?

A Fatigue testing can be applied to various materials, including metals, alloys, polymers, ceramics, and composites.

Q How do I choose the right testing method for my specific application?

A Eurolabs experienced team will work with you to determine the most suitable testing method based on your specific requirements and material selection needs.

Q Can fatigue testing be conducted in-house or must it be outsourced?

A While some companies may have the necessary expertise and equipment to conduct fatigue testing in-house, outsourcing to a reputable laboratory like Eurolab often provides more accurate and reliable results.

Q How long does fatigue testing typically take?

A The duration of fatigue testing varies depending on the specific requirements and complexity of the project. Our team will provide you with a customized timeline to ensure your project is completed efficiently.

Conclusion

In conclusion, fatigue testing plays a critical role in material selection by providing businesses with valuable insights into how different materials behave under repeated stress and strain. By understanding the advantages of using impact of fatigue testing on material selection, companies can reduce the risk of product failure, improve material durability, enhance product performance, and minimize maintenance costs.

At Eurolab, our team of experts is dedicated to helping you navigate the complexities of material selection. With a comprehensive range of laboratory services, including fatigue testing, we can help you make informed decisions about which materials are best suited for your products.

Dont compromise on quality or reliability trust Eurolab to provide you with the expertise and support you need to succeed in todays competitive business landscape. Contact us today to learn more about our fatigue testing services and how they can benefit your business.