Evaluating the Influence of Flux on Solder Joint Quality

Evaluating the Influence of Flux on Solder Joint Quality Unlocking Optimal Reliability and Efficiency

In todays fast-paced electronics industry, the demand for high-quality solder joints is higher than ever. The reliability and performance of electronic devices depend significantly on the quality of their solder joints. However, achieving optimal solder joint quality can be a daunting task, especially when considering the influence of flux on this critical process.

Flux plays a vital role in the soldering process, as it helps to remove oxidation from the metal surfaces and facilitates the flow of molten solder. While flux is essential for successful soldering, excessive or inadequate use of flux can compromise the quality of solder joints. Inadequate flux removal can lead to weak bonds, while excessive flux can cause electrical shorts.

What is Evaluating the Influence of Flux on Solder Joint Quality?

At Eurolab, our team of experienced engineers and technicians offers a specialized laboratory service designed to evaluate the influence of flux on solder joint quality. Our Evaluating the Influence of Flux on Solder Joint Quality (EIFFSQ) service is a comprehensive analysis that assesses the impact of flux on the reliability and performance of electronic devices.

Why is Evaluating the Influence of Flux on Solder Joint Quality Essential for Businesses?

In todays competitive electronics industry, manufacturers are under increasing pressure to deliver high-quality products with minimal defects. The EIFFSQ service from Eurolab provides businesses with a critical tool to ensure optimal solder joint quality and minimize the risk of product failure.

Key Benefits of Evaluating the Influence of Flux on Solder Joint Quality

Improved Product Reliability By evaluating the influence of flux on solder joints, manufacturers can identify potential issues before they become major problems. This proactive approach ensures that products are reliable and meet customer expectations.

Enhanced Efficiency The EIFFSQ service helps manufacturers optimize their soldering processes, reducing production time and increasing efficiency. By identifying areas for improvement, businesses can streamline their operations and focus on delivering high-quality products more quickly.

Reduced Defects and Reworks Inadequate flux removal or excessive flux usage can lead to defective products. The EIFFSQ service identifies potential issues before they cause problems, reducing the need for costly reworks and minimizing waste.

Increased Customer Satisfaction By delivering reliable and high-quality products, manufacturers can build trust with their customers and improve customer satisfaction ratings.

Compliance with Industry Standards The EIFFSQ service ensures that products meet industry standards and regulatory requirements, reducing the risk of non-compliance and costly recalls.

How Does Evaluating the Influence of Flux on Solder Joint Quality Work?

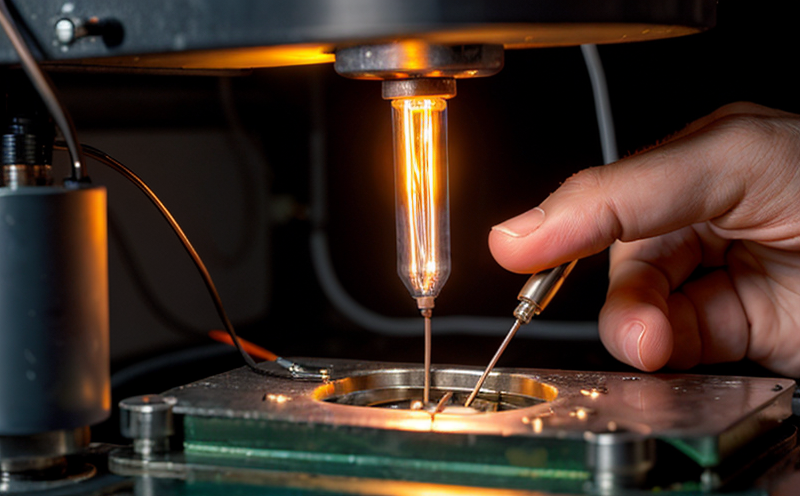

Our expert technicians at Eurolab use advanced equipment and techniques to evaluate the influence of flux on solder joints. The process involves

Sample Preparation We receive samples from manufacturers, which are carefully prepared for analysis.

Flux Removal Analysis Our team analyzes the flux removal process to determine if it is adequate or excessive.

Solder Joint Evaluation We examine the solder joints to assess their quality and identify any potential issues.

Data Analysis and Reporting We provide detailed reports outlining our findings, including recommendations for improving solder joint quality.

Frequently Asked Questions (FAQs)

Q What types of devices can be analyzed using the EIFFSQ service?

A Our team at Eurolab can analyze a wide range of electronic devices, including PCBs, connectors, and other components.

Q How long does the EIFFSQ process take?

A The duration of the EIFFSQ process varies depending on the complexity of the analysis. Typically, our team completes the process within 2-5 working days.

Q Can I get immediate results from the EIFFSQ service?

A Yes, we offer an expedited option for urgent analyses, which can be completed within a shorter timeframe (24-48 hours).

Q Is the EIFFSQ service accredited to industry standards?

A Our team at Eurolab is committed to maintaining the highest standards of quality and accuracy. We adhere to industry standards, including ISO 90012015 and IPC.

Conclusion

In todays competitive electronics industry, manufacturers require tools that help them deliver high-quality products with minimal defects. The Evaluating the Influence of Flux on Solder Joint Quality service from Eurolab provides businesses with a critical tool to ensure optimal solder joint quality and minimize the risk of product failure.

By partnering with us, you can

Improve product reliability and efficiency

Reduce defects and reworks

Increase customer satisfaction

Ensure compliance with industry standards

Dont compromise on product quality. Trust Eurolabs expert engineers and technicians to provide you with accurate and reliable results. Contact us today to learn more about our Evaluating the Influence of Flux on Solder Joint Quality service.

Get a Quote Now

Our team at Eurolab is committed to delivering high-quality services that meet your needs. To get a quote for the EIFFSQ service, please provide us with the following information

Device type and description

Sample quantity and preparation requirements

Desired analysis timeframe (standard or expedited)

We will respond promptly with a customized quote and any additional questions we may have.

Let Eurolabs experts help you optimize your solder joint quality today.